2025 Laser World of Photonics China.

A quick look at what’s new at 2025 Laser World of Photonics China.

Laser World of Photonics China 2025, the annual event for the global laser and optoelectronics industry, successfully concluded at the Shanghai New International Expo from March 11-13. This year marks the 20th anniversary of Laser World of Photonics China, and thanks to the technological breakthroughs and innovative applications of the exhibitors, the show has become a technology vane for laser manufacturing and cutting-edge applications. Although we did not participate in this event due to various factors such as staff travel, as a strategic partner of many well-known laser components and a professional laser automation solution provider, we can still provide customers with the latest and most efficient automated laser marking, cleaning, welding and cutting solutions.

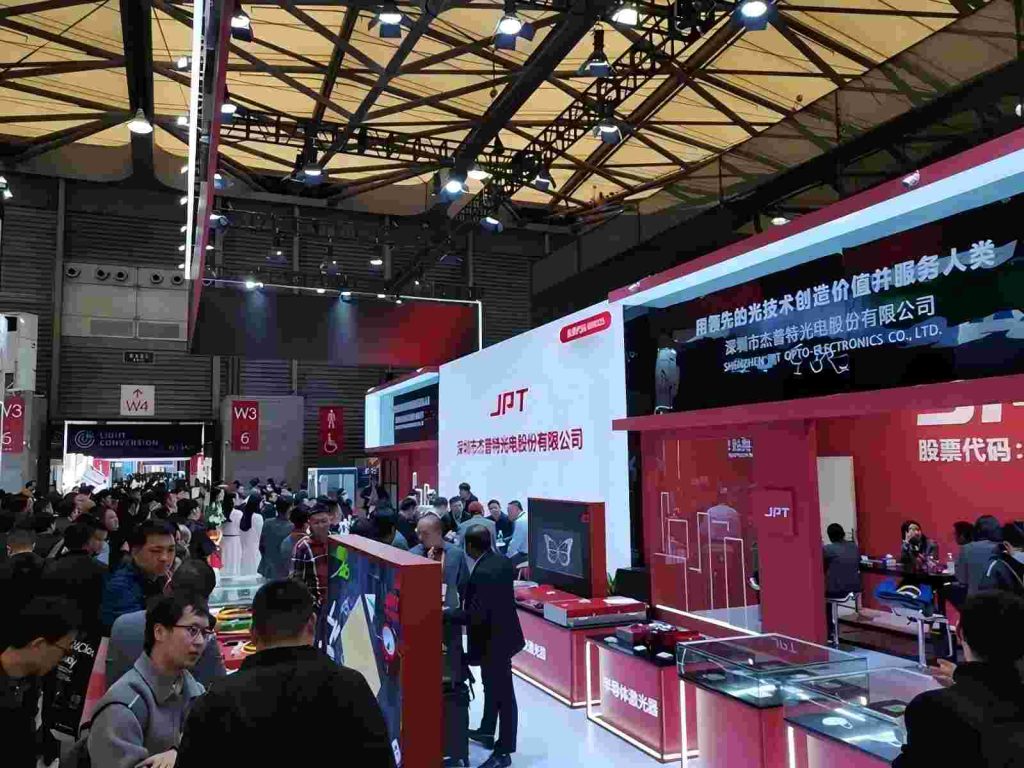

JPT

As the first manufacturer of commercial MOPA pulsed fiber lasers in China and a technology leader in this category, JPT is more focused on laser design and manufacturing than some other manufacturers who are actively expanding their complete machine lines. We equip many customers around the world with lasers using JPT’s MOPA pulsed fiber lasers or solid state UV lasers (DPSS UV), mainly for laser marking, engraving and cleaning applications. At this year’s show, JPT showcased its latest 500W air-cooled MOPA pulsed fiber laser, compact QCW laser, compact 10W/15W solid-state UV laser, and picosecond ultra-high speed red, green and UV lasers that are now available.

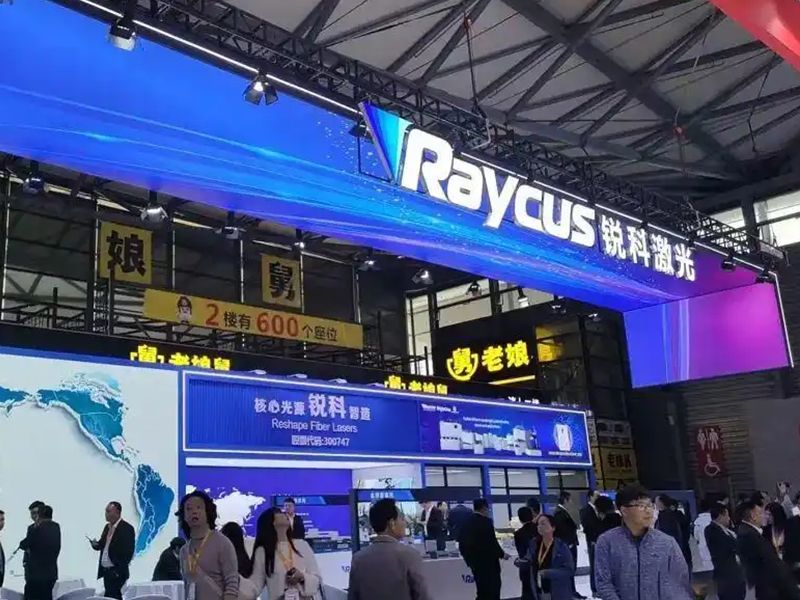

RAYCUS

Raycus introduced new products this year, mainly focusing on the whole machine and the whole business to try to get rid of the current power race and price war in the laser welding and cutting field. The most popular new products are the 10kW single-mode fiber laser based on wavelength-locked semiconductor pumping and the sub-nanometer high-power fiber laser based on this series of technological breakthroughs. These new products are conducive to high-efficiency black marking stainless steel, anodized aluminum alloys and titanium alloys, and high-efficiency translucent paint stripping of plastics, which are conducive to the further popularization of this laser marking process in the appearance of home appliances, consumer electronics, automobiles and daily necessities for personalized content marking. In addition, Raycus’ high-power fiber lasers have become the mainstream choice for laser cladding applications such as SLM 3D printing, mold repair, parts hardening and strengthening, and other heavy-duty industrial equipment.

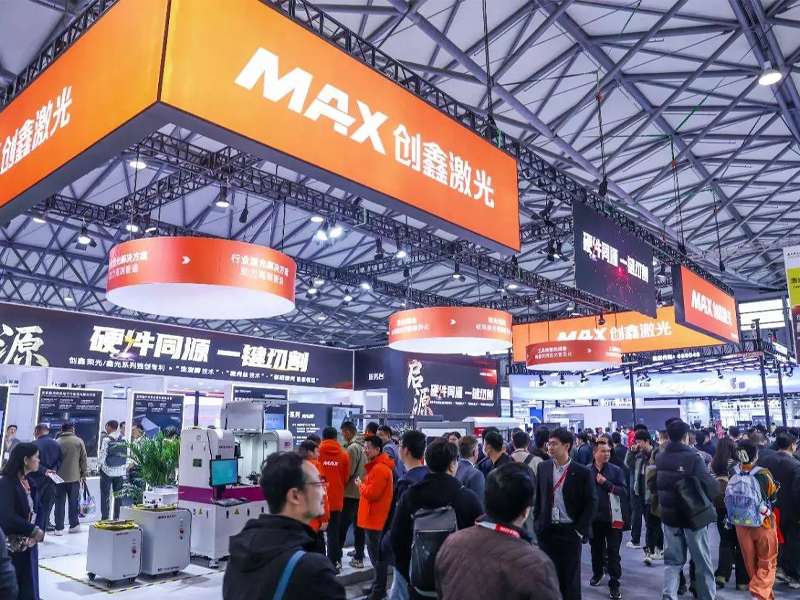

MAX

Similar to Raycus, MAX‘s new products this year also focus on vertical segments of the whole machine and the whole line of solutions to avoid the market competition of rolled specification and rolled price. For us and our customers, the most important new product from MAX this year is the 20kW single-mode fiber laser. In addition to the power upgrade, the biggest highlight of this series is the extreme miniaturization and lightweight, and more than 50% volume reduction has been achieved in both single-mode 20kW and multi-mode 60kW lasers. In addition, this series of technological breakthroughs has also been applied to the conventional air-cooled 1500W, 2000W, and 3000W lasers, the size and weight of the series of lasers have been reduced by more than 60%, which is conducive to the realization of smaller and lighter air-cooled continuously-wave (CW) laser cleaners and welders.

Inno

In recent years, we have provided laser marking solutions to a number of mid- to high-end direct-to-consumer brands and manufacturers using Inno‘s DPSS UV lasers, and have received positive feedback from our customers for the low-cost FIT Series, mainstream FOTIA Series, and high-end FORMULA Series UV lasers. At this show, Inno displayed its newly upgraded FOTIA PRO Series, nanosecond FORMULA ULTRA Series, and picosecond AMARK Series solid-state UV lasers, further expanding its green UV laser marking product line. We especially recommend the use of Inno lasers on plastic bags, bottles and boxes for food and pharmaceuticals, replacing the more traditional CO2 laser marking with higher contrast, lower thermal deformation and sharper lines for traceability markings such as production dates, expiration dates and serial numbers.

In addition, we can also provide a series of international advanced automated laser marking, cleaning, welding and cutting solutions with the brand exhibitors, such as advanced lasers from IPG, Coherent, Huaray and more brands, Han’s Laser’s motion control system, Han’s Laser’s welding head, Bochu’s precision laser cutting control system, etc., in order to meet the different customers for the laser of all kinds of requirements.