5 FAQs About UV Laser Marking Machine as Glass Laser Marking Machine

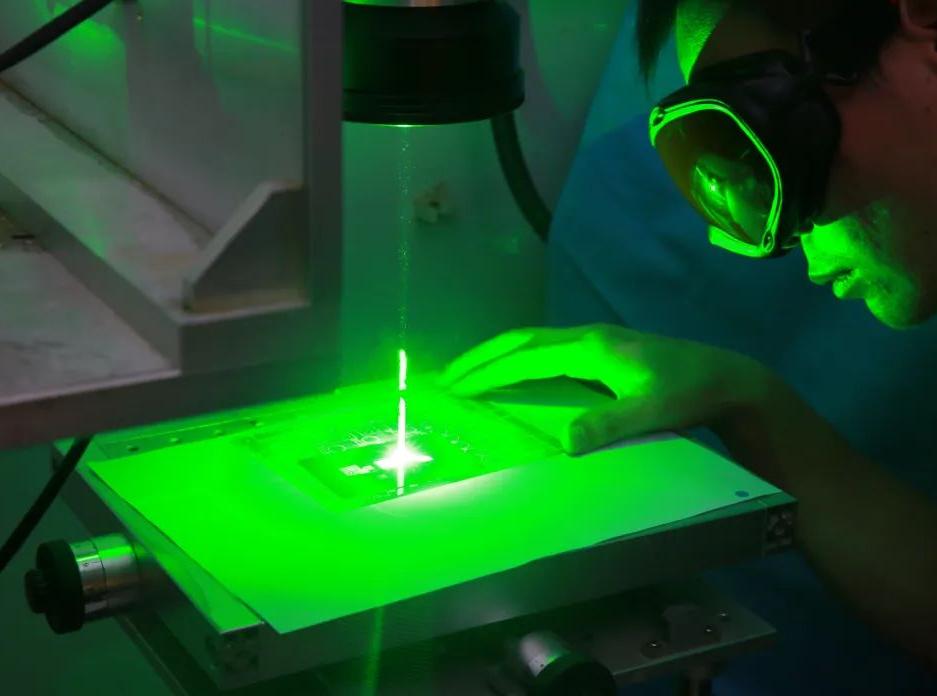

UV laser marking machines have become increasingly popular for marking glass due to their ability to produce precise, permanent, and high-quality marks. This technology offers several advantages over traditional marking methods, making it a preferred choice for many industries. Zixu published this article and aims to provide answers to some of the most frequently asked questions about UV laser marking machines as glass laser marking machines. By understanding these key points, you can better assess whether this technology is suitable for your specific glass marking needs.

Q1: Why Choose UV Laser Marking Machine as Glass Laser Marking Machine?

Precision and Detail

- High-resolution markings: UV lasers can create extremely fine and detailed markings, even on small or intricate designs.

- Accurate positioning: The laser beam can be precisely positioned to ensure accurate marking of various shapes and patterns.

Permanence and Durability

- Resistant to fading: UV laser-marked glass is resistant to fading, even when exposed to sunlight or harsh weather conditions.

- Scratch-resistant: The markings are typically scratch-resistant, ensuring they remain legible over time.

Versatility and Flexibility

- Wide range of applications: UV laser marking can be used for various applications, including logos, barcodes, serial numbers, and decorative patterns.

- Adaptable to different glass types: The process can be adjusted to accommodate different types of glass, such as soda-lime, borosilicate, and tempered glass.

Efficiency and Speed

- Fast marking times: UV lasers can mark glass quickly, improving production efficiency.

- Minimal downtime: The non-contact nature of laser marking reduces the need for maintenance and downtime.

Non-Destructive and Environmentally Friendly

- No physical damage: The laser marking process does not cause any physical damage to the glass, preserving its integrity.

- Minimal environmental impact: UV lasers are generally more energy-efficient and produce fewer emissions compared to traditional marking methods.

In summary, UV laser marking machines offer a combination of precision, durability, versatility, efficiency, and environmental friendliness, making them an excellent choice for marking glass in various industries.

Q2: Can UV Laser Marking Be Used for Marking Glass That Is Already Coated or Treated?

Yes, UV laser marking can indeed be a viable option for glass that has already been coated or treated. However, it’s essential to carefully consider the specific characteristics of the coating or treatment to ensure optimal results. Here’s a more detailed breakdown of the factors involved:

Coating Type

- Reflective Coatings: Highly reflective coatings can deflect the laser beam, reducing its effectiveness. In such cases, the coating may need to be removed or modified before marking.

- Protective Coatings: Coatings designed to protect the glass from scratches or damage can sometimes interfere with laser marking. The coating’s thickness and composition can influence its interaction with the laser beam.

- Color-Changing Coatings: Coatings that change color under certain conditions may not respond well to laser marking, as the heat generated by the laser could affect the coating’s properties.

Treatment Type

- Tempering: Tempered glass, which is strengthened through a heat treatment process, can generally be marked with UV lasers. However, the specific tempering process and the glass’s composition may influence the marking results.

- Annealing: Annealed glass, which is heated and cooled slowly to relieve internal stresses, can also be marked with UV lasers. However, the annealing process may affect the glass’s surface properties, potentially influencing the marking outcome.

Laser Parameters

- Power: The laser power can be adjusted to penetrate through coatings or treatments of varying thicknesses. A higher power may be necessary for thicker or more reflective coatings.

- Wavelength: The wavelength of the UV laser can be optimized to interact effectively with specific coating materials. Some coatings may be more sensitive to certain wavelengths.

- Pulse Duration: The pulse duration can be adjusted to control the amount of energy delivered to the glass surface. Shorter pulses can help minimize damage to coatings or treatments.

Q3: Can UV Laser Marking Be Used for Marking Glass with Curved Surfaces?

Yes, UV laser marking can be used for marking glass with curved surfaces. However, it requires specialized equipment and techniques to ensure accurate and consistent marking. Here’s how it’s typically done:

- Motion Control: The laser head must be able to move in multiple axes to follow the contours of the curved surface. This is achieved using precise motion control systems.

- Focus Adjustment: The laser beam must be focused accurately at the marking point, even on curved surfaces. This requires real-time focus adjustment based on the surface geometry.

- Software Integration: Specialized software is used to control the laser’s movement and focus, as well as to compensate for the curvature of the glass.

- Marking Strategies: Different marking strategies may be employed for curved surfaces, such as using multiple passes or adjusting the laser power to account for varying distances.

By utilizing these techniques, UV laser marking can effectively create high-quality marks on glass with complex shapes and curves.

Q4: Can UV Laser Marking Affect the Glass’s Physical Properties?

Generally, UV laser marking does not significantly affect the glass’s physical properties. The marking process is primarily confined to a thin surface layer, and the bulk of the glass remains unaffected. However, there are a few factors to consider:

Glass Type

- Hardness: Harder glasses, such as tempered glass, may be less susceptible to changes from laser marking due to their increased resistance to stress.

- Composition: The specific composition of the glass can affect its response to laser energy. For instance, glasses containing impurities or additives may exhibit different behaviors.

- Thickness: Thicker glass may require higher laser power to achieve the desired marking depth, which could potentially affect its properties more significantly.

Marking Parameters

- Power: Excessive laser power can lead to deeper marks, which may weaken the glass surface in localized areas.

- Speed: Slower marking speeds can allow for more controlled energy delivery, reducing the risk of damage.

- Pulse Duration: Short pulse durations can minimize thermal effects, preserving the glass’s physical properties.

Post-Processing

- Heat Treatment: Heat treatments applied after laser marking can potentially affect the glass’s properties, especially if the marking process has introduced stress or microcracks.

- Coatings: Coatings applied to the marked glass can alter its surface characteristics and may interact with any residual effects of the laser marking process.

Q5: Can UV Laser Marking Be Used for Creating Intricate Patterns or Designs on Glass?

Yes, UV laser marking is well-suited for creating intricate patterns or designs on glass. The high precision and detail capabilities of UV lasers allow for the creation of complex markings, including:

- Logos and branding: Detailed logos and branding elements can be marked onto glass surfaces.

- Barcodes and QR codes: High-quality barcodes and QR codes can be etched onto glass for identification and tracking purposes.

- Artwork and decorative patterns: Intricate artwork and decorative patterns can be created using various laser marking techniques.

- Text and numbering: Clear and legible text and numbering can be marked onto glass for labeling or identification.

The ability to create intricate designs depends on factors such as the laser’s power, resolution, and the software used to control the marking process. With the right equipment and expertise, UV laser marking can be used to produce stunning and detailed patterns on glass.

UV Laser Marking: A Versatile Solution for Glass

UV laser marking machines offer a versatile and efficient solution for marking glass. Their ability to produce precise, permanent, and high-quality marks, combined with their versatility in handling different glass types and applications, makes them a valuable asset for various industries. By carefully considering the factors discussed by UV laser marking machine supplier Zixu, such as coating compatibility, marking on curved surfaces, potential effects on glass properties, and the ability to create intricate designs, you can make an informed decision about whether a UV laser marking machine is the right choice for your glass marking requirements.

Recommended Products