A New Welding Choice: Comparison of Handheld Laser Welding Machines and TIG Welding

The welding industry is undergoing a seismic shift as innovative technologies challenge traditional methods. Among these advancements, handheld laser welding machines are emerging as game-changers. Meanwhile, TIG (Tungsten Inert Gas) welding, a long-standing favorite for precision work, continues to hold its ground in specific applications.

This article provides a detailed comparison of these two technologies, focusing on their strengths, limitations, and real-world applications. Whether you’re a factory manager seeking cost-effective solutions or an engineer exploring advanced welding techniques, this guide will help you determine which method aligns with your needs.

What Are Handheld Laser Welding Machines and TIG Welding?

Handheld Laser Welding Machines:

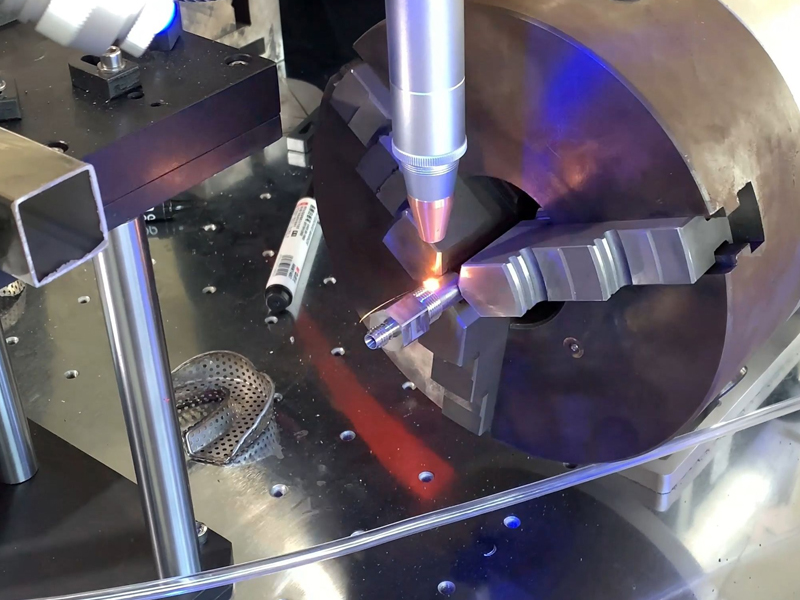

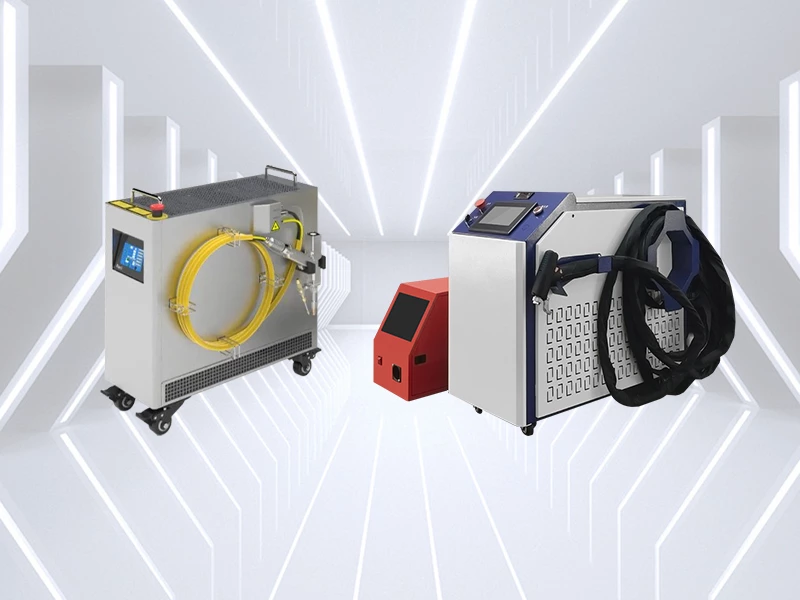

Handheld laser welding machines use a focused laser beam to melt and fuse materials. This technology offers unparalleled precision and speed, allowing for intricate welding with minimal heat input. The portability of these machines enables on-site repairs and flexible manufacturing processes. Zixu is at the forefront of this technology, providing robust and reliable China handheld laser welding machines designed for various industrial applications.

These machines typically consist of a laser source, fiber optic cable, and a handheld welding gun. The laser beam is precisely directed onto the workpiece, creating narrow and deep welds with minimal deformation. These devices are ideal for precision tasks, ensuring seamless operation on stainless steel, aluminum, and carbon steel.

TIG Welding:

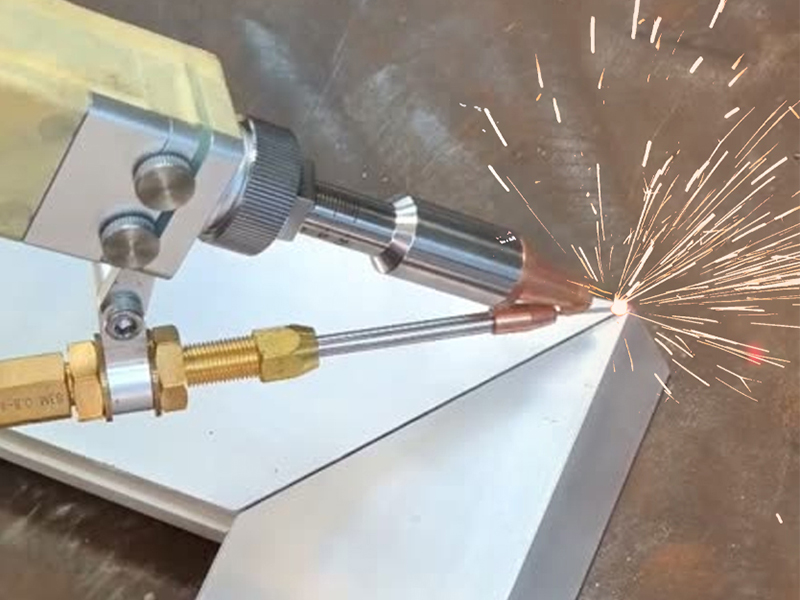

TIG welding relies on a non-consumable tungsten electrode to generate an arc that heats the workpiece, while an inert gas (typically argon) shields the weld pool from contamination. TIG welding is known for producing clean, high-quality welds and is widely used in aerospace, automotive, and artistic metalwork. However, it requires a skilled operator and is generally slower than laser welding.

Advantages of Handheld Laser Welding Machines

Micro-Welding and High-Quality Welding

Handheld laser welding machines enable micro-welding with extreme precision. The laser beam provides a small, concentrated heat source, allowing for delicate and detailed welds with minimal spatter. This makes them ideal for applications requiring aesthetically appealing and structurally sound welds, such as electronics and medical devices.

No Loss, Environmentally Friendly, and Energy-Saving

Unlike TIG welding, handheld laser welding minimizes material waste and eliminates the need for filler materials in many cases. The process is also more energy-efficient, as it requires less power to achieve deep penetration and strong welds. Additionally, laser welding produces low emissions, making it an environmentally friendly alternative.

Flexible and Versatile, Widely Applicable

Handheld laser welding machine offers unmatched flexibility in terms of portability and ease of operation. Operators can work on complex geometries and hard-to-reach areas without the constraints of traditional welding setups. Industries such as automotive, aerospace, jewelry, and construction benefit greatly from this versatility.

Fast Speed, High Power, and Small Deformation

Handheld laser welding machines deliver high-speed welding with minimal heat-affected zones. This results in less thermal distortion, reducing post-weld processing and improving efficiency. Compared to TIG welding, laser welding achieves stronger bonds at a fraction of the time, making it an attractive choice for high-volume production.

Advantages and Limitations of Traditional TIG Welding

Advantages:

- Exceptional Weld Aesthetics: Produces smooth, spatter-free surfaces. Strong and reliable joints suitable for critical applications.

- Material Versatility: Applicable to a wide range of metals, effective on copper, titanium, and rare alloys, including stainless steel and aluminum.

- Mature Process: Decades of industry adoption.

Limitations:

- High Labor Costs: Requires highly skilled operators, making operator training essential.

- Slow Speed: Average speed of 0.3-0.5 meters per minute. Slower welding speed compared to handheld laser welding machines.

- Thermal Distortion: Higher heat input leads to greater material deformation.

Handheld Laser Welding Machine vs. TIG Welding: In-Depth Comparison

In recent years, the development momentum of handheld laser welding machines has been strong, with major manufacturers introducing their own models. Judging from their functional characteristics, small laser welding machines are most likely to replace traditional TIG welding processes. Compared to TIG welding, what advantages do small laser welding machines have?

| Feature | Handheld Laser Welding Machines | TIG Welding |

| Speed | Faster, up to 10 times quicker | Slower process |

| Precision | High, suitable for micro-welding | High, but depends on operator skill |

| Heat Affected Zone | Minimal, reducing deformation | Larger, causing material distortion |

| Versatility | Portable and flexible | Limited flexibility due to setup requirements |

| Energy Efficiency | More efficient, requires less power | Higher energy consumption |

| Cost | Higher initial cost, but lower operational expenses | Lower equipment cost, but higher operational expenses |

| Skill Requirement | Easy to learn, user-friendly | Requires extensive training and experience |

Applications of Handheld Laser Welding Machines

Handheld laser welding machines are transforming multiple industries due to their efficiency and versatility. Some key applications include:

Automotive Industry: Welding of car bodies, exhaust systems, and intricate metal components.

Aerospace Industry: High-precision welding for aircraft components requiring lightweight and strong materials.

Jewelry and Watchmaking: Micro-welding for delicate and intricate designs.

Medical Equipment: Seamless welding of surgical instruments and medical devices.

Electronics Industry: Solder-free welding for electronic components, ensuring high conductivity and reliability.

Conclusion

Both handheld laser welding machines and TIG welding have their respective advantages, but for industries seeking speed, precision, and energy efficiency, laser welding is the superior choice. With leading manufacturers like Zixu offering state-of-the-art China handheld laser welding machines, businesses can enhance productivity while maintaining high-quality welding standards. As the demand for efficient and versatile welding solutions grows, laser welding is poised to become the preferred choice for modern manufacturing.

Recommended Products