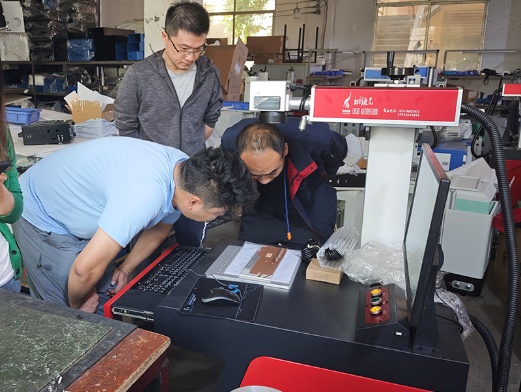

April 19, ZIXU Sample Cleaning for a Visited Electronic Industry Customer, Helping It for Potential Both Quality and Productivity Growth

In early April, we received a request from a manufacturer in the 3C industry, also located in Chongqing, to visit and clean samples for testing. On a Friday morning, the customer’s Vice President of Technology led engineers to our facility and brought several samples of aluminum substrates with pure copper. After a thorough discussion with the customer about their cleaning goals and process requirements, we recommended that they use the MOPA fiber laser marker instead of a laser cleaner to clean these parts. Although the MOPA fiber laser marker is less efficient than a dedicated pulsed laser cleaning system of the same power due to the difference in laser and galvanometer tuning, the powerful marking software can reduce the area to be cleaned by entering specific pattern sizes and shapes, achieve stable cleaning quality based on a fixed focal length and parameter settings, and achieve easier and more efficient workpiece changeover by using customized fixture.

For reasons of confidentiality, we cannot show a sample of the workpiece with a specific raised shape, but only the workpiece initially provided by the customer for testing the material. The surface of the workpieces forms a thin oxidized layer of small black dots that are difficult to see with the naked eye due to the process, and according to the customer, the thickness of the oxidized layer scanned by an electron microscope is only 5 to 12 microns. Therefore, the customer initially preferred to use a lower power continuous or pulsed laser cleaner for rapid scanning. After testing, although the laser cleaner can quickly remove the oxide layer, but whether it is operated by handheld or CNC platform, the heat and energy of the cleaner is very easy to damage the workpiece, and it is difficult to guarantee the cleaning yield, and the cost of a single workpiece according to the customer is more than 300 US dollars.

Since the surface of copper is not flat, the customer wanted to improve the flatness of the surface while laser cleaning the oxide layer, which would improve the efficiency of the subsequent process. In the end, we used a 300W MOPA fiber laser marker with a high-speed scanning galvanometer for the test and tried dozens of different settings to form enough samples for the customer to analyze with an electron microscope. Based on the results of the initial evaluation by touch and the naked eye, the customer believes that the cleaning effect and the performance of the cleaned substrate are best when using the highest power and the highest pulse width setting with two cross-fills at different angles at a speed of 9000 mm/sec. The customer is pleased with the results to date and signed a Letter of Intent on the spot for several systems with customized semi-automatic loading fixtures totaling nearly half a million US dollars. The customer said that although the cost is not low, this type of equipment will help them significantly improve yield and processing efficiency, and be able to recoup the investment in one year by reducing rework and outsourcing cleaning.