Automotive

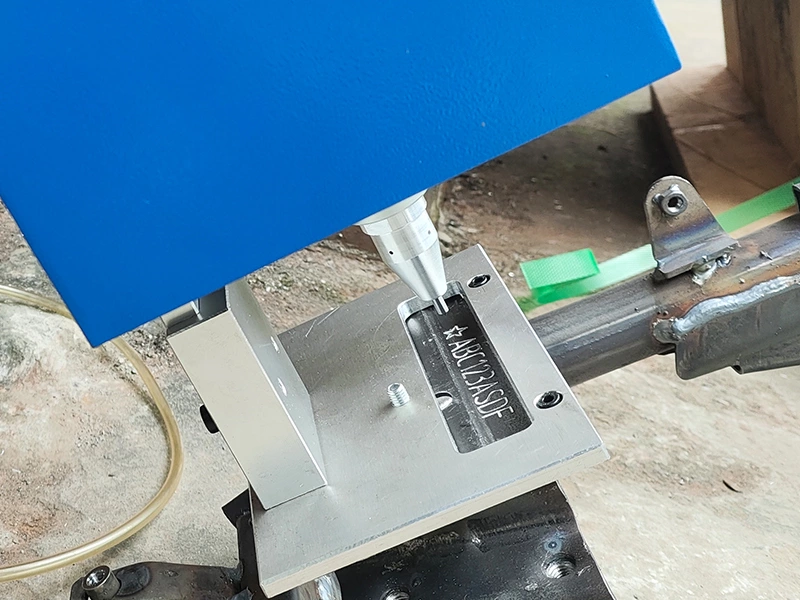

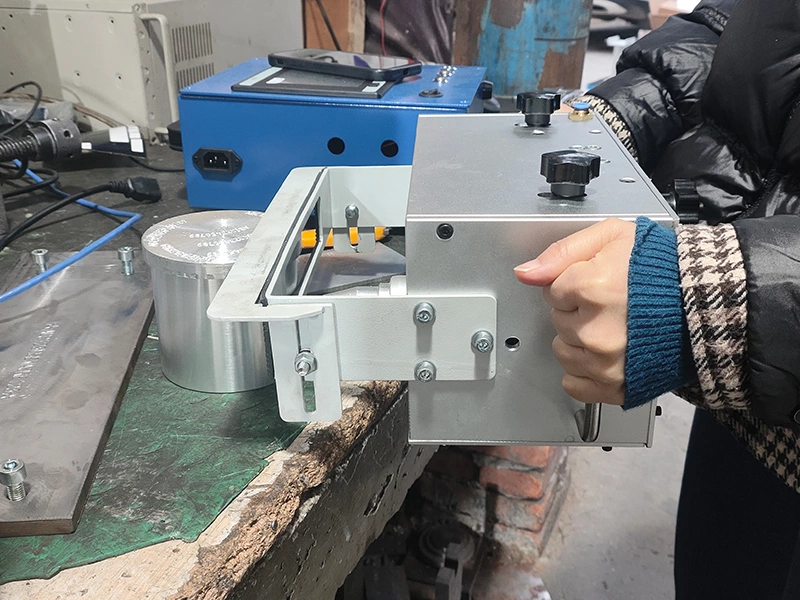

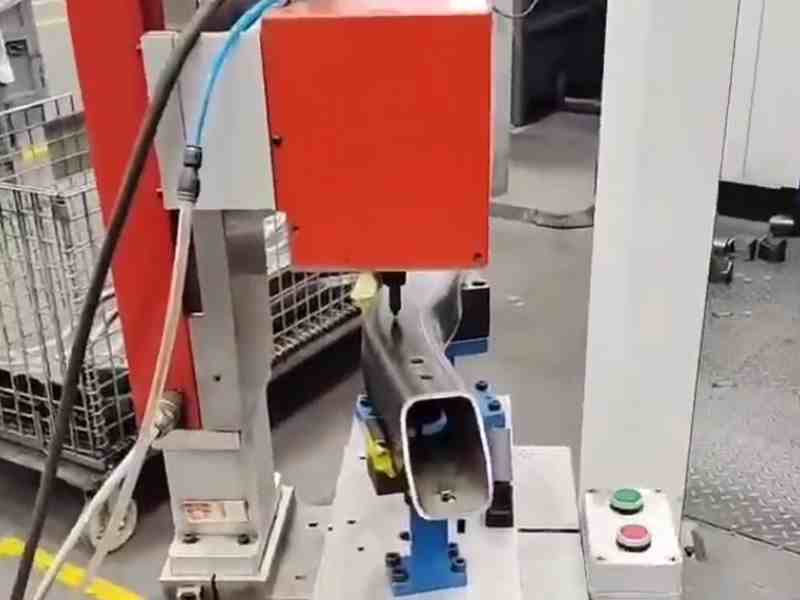

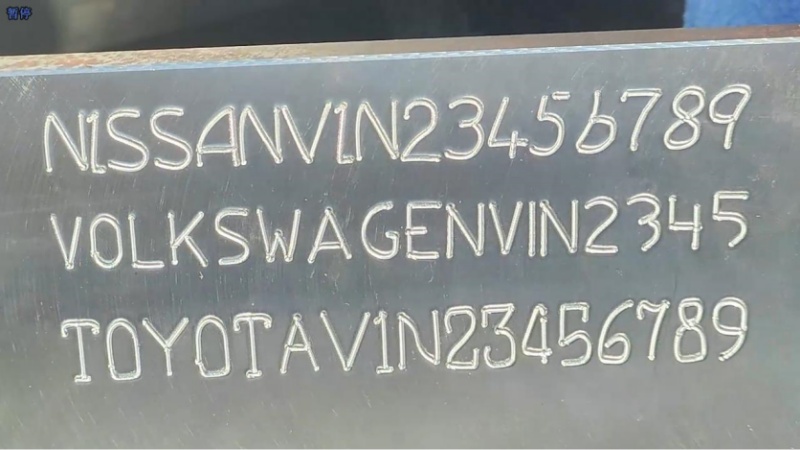

The 17-digit VIN is the equivalent of a vehicle ID, and car and motorcycle manufacturers invariably use pneumatic pinning, pneumatic scribing and laser engraving for permanent marking, while the used car market also requires re-marking of rusted or worn chassis. We started our business with VIN marking and expanded it to include traceability marking, laser welding and cleaning of all types of components for the automotive industry to provide a one-stop solution.

Technologies For Automotive

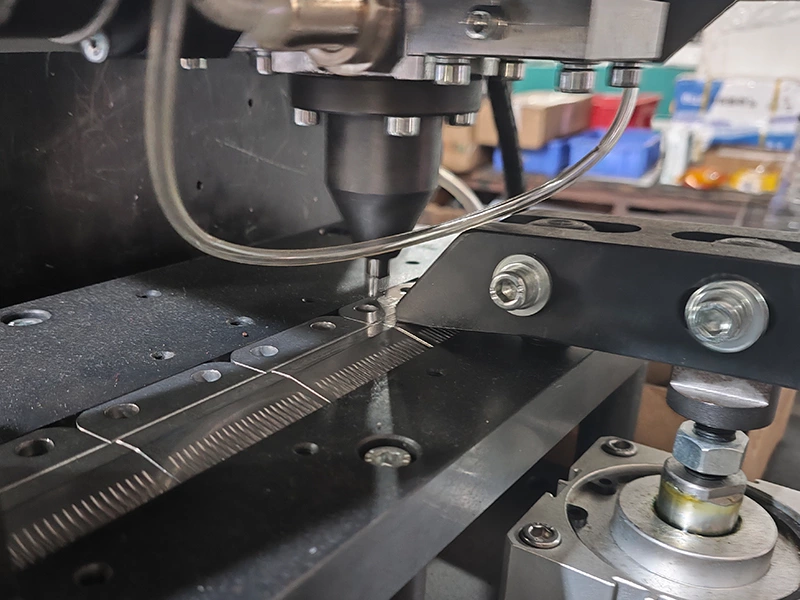

The automotive industry uses a wide range of standardized and non-standardized metal parts that require Direct Part Marking (DPM). The identification and traceability of these critical metal parts is critical to the quality and subsequent maintenance of the vehicle. We entered this field with pneumatic needle marking and over the years we are now able to offer a wide range of marking solutions from mobile marking to fully automated in-line marking including pneumatic needle, pneumatic scribing and electric needle.

- Fast: to mark with same specific depth such as 0.3mm, our peen marking machine is 8~10X faster than a 100W fiber laser system;

- Depth: our peen marking machine offer 0.1~0.3mm depth in one pass, and able to precise repeat for deeper marks;

- Traceability: in addition to serial numbers or date marks, our peen markers can mark scannable DPM or QR codes for digital management.

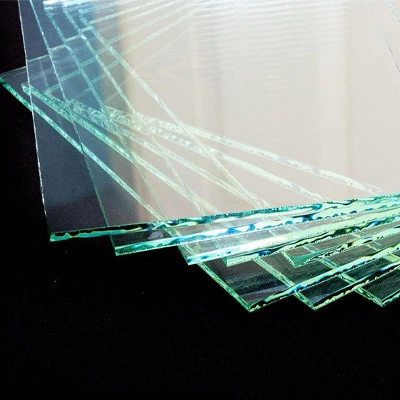

In fact, the automotive industry has tended to switch to laser marking, especially for smaller metal parts and other non-metallic materials such as circuit boards, wires, glass, etc., as well as for some brands of VINs. In addition to desktop and automated workstations, we have a wide range of portable laser marking machines that allow our customers to work where and when they want.

- Quiet: laser marking of metal also generates noise especially deep engraving, but this is negligible compared to the peen marking process;

- Accuracy: Laser marking can mark metal in extremely small size, such as 3.7*3.7mm Data Matrix code or 0.03mm line width characters, which are impossible for peen marking;

- Visibility: Using MOPA fiber or UV laser for laser annealing instead of engraving for black or other color marking on metal workpiece with high contrast.

Laser welding is widely used in the automotive industry, from welding subsystems such as engines and exhaust pipes to robotic welding of frames and complete vehicles. The use of automated laser table welders provides extremely consistent weld quality compared to MAG and is simpler in design, making it more suitable for integrated automation. Precision laser welding, including galvo welding, is also used in the manufacture of electric vehicle batteries.

- Efficiency: highly automated CNC or robotic laser welding solutions provide excellent welding speed and quality, effectively reducing manufacturing costs throughout the lifecycle;

- Easy to operate: Common automatic laser welders simply import engineering drawings and go, and are easy to maintain and calibrate;

- Precise: QCW or MOPA fiber laser welding system produces extremely small spots and weld marks for high-precision welding of thin sheets, films, electronic circuits and more.

Laser cleaning technology, which does not require detergents or intermediate catalysts, is now widely used in the automotive industry to clean oil and grease from all types of metal parts and rubber residue from tire molds. Compared with traditional cleaning methods, laser cleaning can be 2 to 10 times faster and easier to automate the cleaning process, resulting in less damage and higher cleaning efficiency.

- Efficient: the high-energy laser beam vaporizes contaminants in a very short time with minimal damage to the workpiece.

- Non-consumable: laser cleaning can be operated without detergents or catalysts, significant savings for high-volume industrial metal de-rusting.

- Non-contact: the laser beam can remove rust, oxides, oil, grease, paint, and coatings at a distance, making it suitable for cleaning hard-to-reach workpieces such as tire molds.

Explore Our Machines For Automotive

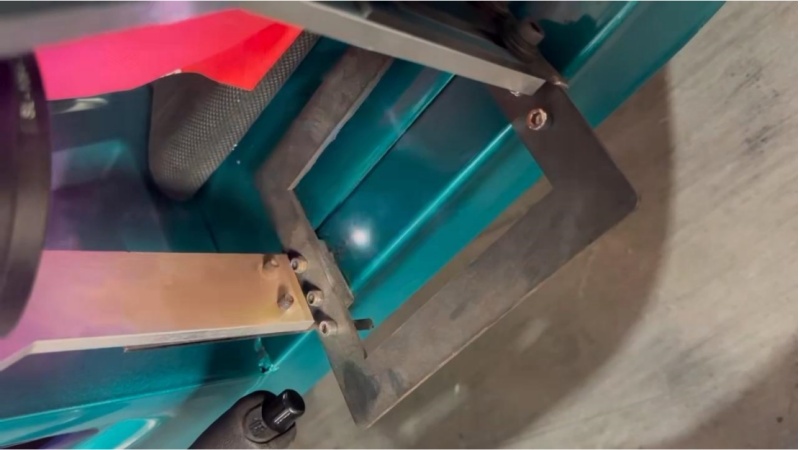

The pneumatic peen VIN Marker is the product we started our business with and by far the product we have designed, manufactured and sold the most. We offer a range of standardized and customizable solutions, from in-line dot peen markers or scribers for manufacturing customers to portable pneumatic and electric dot markers for small repair shops and ground transportation companies.

In addition to the hardware and software of the marking machine itself, we have also accumulated a great deal of experience and brand fonts over the years. Whether it’s pneumatic dot peen, pneumatic scribing, electric dot peen or laser VIN marking, we offer the same equipment and brand fonts originally produced by the world’s major brands, allowing our customers to keep their VIN codes visible.

Because of its excellent marking and engraving results, laser marking is often used for materials that are more in contact with the end user, such as custom marking on various types of leather, custom text marking on automotive paint, engraving on glass and crystal, and translucent effects on some buttons, in addition to VIN coding and part quality tracking.

Automotive manufacturers around the world are now fully utilizing all types of automation technology, from metal parts to electronic components to EV batteries, and welding robots are most commonly used for more complex tasks such as frame welding. With many years of experience in automated welding, we are able to offer a wide range of automated welding solutions.

Laser cleaning is still in its infancy in the automotive industry, mainly for degreasing metal raw materials and components in the manufacturing process, pre-weld treatment and cleaning tire mold residue, followed by a small number of applications such as removing old paint from old cars and cleaning carbon and oil deposits in exhaust pipes. Because the cost of automated cleaning of complex shapes is still much higher than that of dry ice cleaning systems, it is still in the market penetration stage.

Related Cases

Want an un art handing video demonstration on specialized material? Looking for a solution to your specialized environment or automatic process demand?