Can Laser Marking On Wood?

Laser marking on wood has become increasingly popular across industries due to its precision, versatility, and ability to create intricate designs without damaging the material. The process involves using a laser beam to mark or engrave various types of wood for different applications, ranging from decorative and artistic projects to industrial labeling and product branding.

What is Laser Marking On Wood

Laser marking on wood is a precise and non-contact process that involves using a focused laser beam to create permanent marks or engravings on wood surfaces. This method works by emitting a high-energy laser that interacts with the surface of the wood, causing localized heating, burning, or vaporization. As a result, the laser alters the appearance of the wood—leaving behind darkened, lightened, or etched designs, depending on the specific technique used. The beauty of laser marking is that it can produce detailed, intricate designs without compromising the wood’s structural integrity or requiring physical contact with the material.

How Does Laser Marking Work?

Laser marking on wood works by focusing a laser beam on specific areas of the wood’s surface. The energy from the laser heats and vaporizes the upper layers, leaving a precise mark that matches the design programmed into the machine. The intensity, speed, and focus of the laser can be adjusted, giving operators control over the depth and style of the mark.

Different settings produce varied effects. For instance, adjusting the power and speed allows the operator to either engrave deeply into the wood or create a more subtle surface mark. High-power settings burn deeper, resulting in strong contrast and bold engravings, while lower-power settings create more delicate, surface-level marks. These subtle marks are ideal for decorative or intricate designs, giving the operator flexibility to achieve a wide range of visual outcomes.

Why Use Laser Marking for Wood?

One of the primary advantages of laser marking on wood is its versatility:

- Wide Material Compatibility: Laser marking works effectively on nearly all types of wood, including softwoods, hardwoods, plywood, and MDF (medium-density fiberboard). This flexibility makes it ideal for a variety of applications, from signage to decorative items.

- Precision: The laser marking process offers exceptional accuracy, allowing for intricate details, sharp lines, and even complex images or text. This level of precision surpasses manual carving and traditional burning techniques, providing clean, professional results every time.

Another key benefit of laser marking is its efficiency:

- Non-Contact Process: Unlike traditional methods, laser marking does not involve direct physical contact with the wood, reducing the risk of damage like warping or splintering.

- Minimizes Waste: The highly controlled laser process targets only specific areas, ensuring minimal waste. Additionally, it eliminates the need for extra tools or consumables, such as ink or chemicals, further increasing cost efficiency.

What Type of Laser Marks Wood

Several types of lasers can be used to mark wood, each with different characteristics and suitability for the material. The most commonly used lasers for wood marking include:

1. CO2 Lasers

CO2 lasers are the most widely used for marking wood. They operate by emitting a laser beam in the infrared spectrum, which is absorbed efficiently by organic materials like wood. This absorption causes the surface of the wood to heat up rapidly, resulting in vaporization or burning, which creates a clean and precise mark. CO2 lasers are highly versatile, capable of engraving, cutting, and marking wood at varying depths. Their ability to create intricate designs makes them the top choice for most wood marking applications, from decorative engravings to industrial labeling.

3. Diode Lasers

Diode lasers are a lower-power option compared to CO2 and fiber lasers, and they can be used for light surface marking on wood. These lasers are often employed for hobbyist or small-scale projects due to their lower cost and accessibility. Diode lasers are most effective on softer woods or when only light etching is required, such as for creating surface patterns, small texts, or simple designs. While not as powerful as CO2 lasers, diode lasers can still achieve good results on wood with the proper settings and patience.

In a word, CO2 lasers are the best option for most wood marking projects due to their power, precision, and versatility. Diode lasers may be used in certain niche applications, but they are less efficient for deep or detailed markings on wood surfaces.

Can Fiber Lasers Used to Mark Wood?

While fiber lasers can be used to mark wood, the results are often less satisfactory. The shorter wavelength of fiber laser light tends to be absorbed unevenly by wood, leading to inconsistent and often unattractive marks. This can result in charred areas, uneven lines, and overall poor-quality engravings.

- Uncontrolled Absorption: Wood has a complex structure with varying densities and moisture content. This can lead to uneven absorption of the laser beam, resulting in inconsistent and often charred marks.

- Short Wavelength: Fiber lasers emit a short wavelength (typically 1064nm), which is less efficiently absorbed by wood compared to longer wavelengths used by CO2 lasers. This can lead to less effective marking and a higher risk of fire.

- Fire Hazard: Due to the uncontrolled absorption and shorter wavelength, there is a higher risk of wood igniting when using a fiber laser. This can be dangerous and damage the material being marked.

For marking wood, CO2 lasers are generally preferred as they emit a longer wavelength (10.6µm) that is more effectively absorbed by wood, leading to cleaner and more consistent marks.

So it is not suggested to use fiber laser to mark on wood.

Wood Laser Marking Machine Applications

Wood laser marking machines have a wide array of applications across various industries, thanks to their precision, efficiency, and versatility. Here are some of the key areas where these machines are utilized:

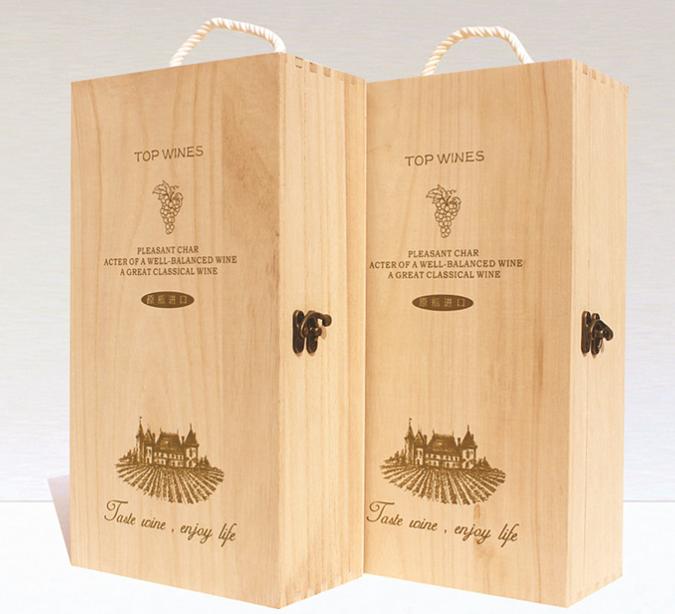

Product Branding and Labeling

Many businesses use wood laser marking machines for branding and labeling their products. This includes engraving logos, serial numbers, barcodes, and other identifying information directly onto wooden products. For instance, furniture manufacturers may mark their logo onto tables, chairs, and cabinets, providing a professional finish and enhancing brand recognition. Laser marking ensures that these labels are durable, permanent, and resistant to wear, which is crucial for maintaining product integrity and authenticity over time.

Industrial Applications

In industrial settings, wood laser marking machines are used for labeling and identification purposes. They can mark plywood, MDF, and other engineered wood products with important information such as part numbers, dimensions, and handling instructions. This application is crucial for maintaining organization and traceability within manufacturing processes. Laser marking provides a clean and legible alternative to traditional labeling methods, reducing the risk of mislabeling and improving overall efficiency.

Furniture Manufacturing

The furniture industry benefits significantly from laser marking technology. Manufacturers use laser marking machines to engrave intricate designs or branding onto furniture pieces, such as tables, chairs, and cabinets. This adds a unique touch to the products, increasing their value and appeal to consumers. Additionally, laser marking can be used to create assembly instructions, safety labels, or even design elements that enhance the functionality and aesthetics of the furniture. The precision of laser marking ensures that even the smallest details are rendered beautifully, contributing to the overall quality of the finished product.

Art and Design

Laser marking has revolutionized the art and design industries, allowing artists and craftsmen to create intricate and detailed woodwork. Artists can use laser marking machines to engrave elaborate designs, patterns, and textures onto wooden surfaces, producing stunning visual effects that enhance the aesthetic appeal of their creations. This technology enables artists to explore new creative avenues by allowing for precise reproductions of complex designs that would be time-consuming and challenging to achieve by hand. From customized sculptures and decorative panels to personalized home decor items, laser marking empowers artists to push the boundaries of traditional woodworking.

Laser marking on wood is a versatile, efficient, and precise technology that offers numerous benefits across various industries. With the right laser, such as a CO2 laser, and the proper machine, users can achieve exceptional results, making this technique a valuable tool for both hobbyists and professionals alike. As technology continues to evolve, the potential for wood laser marking will only grow, opening up new possibilities for creativity and functionality.

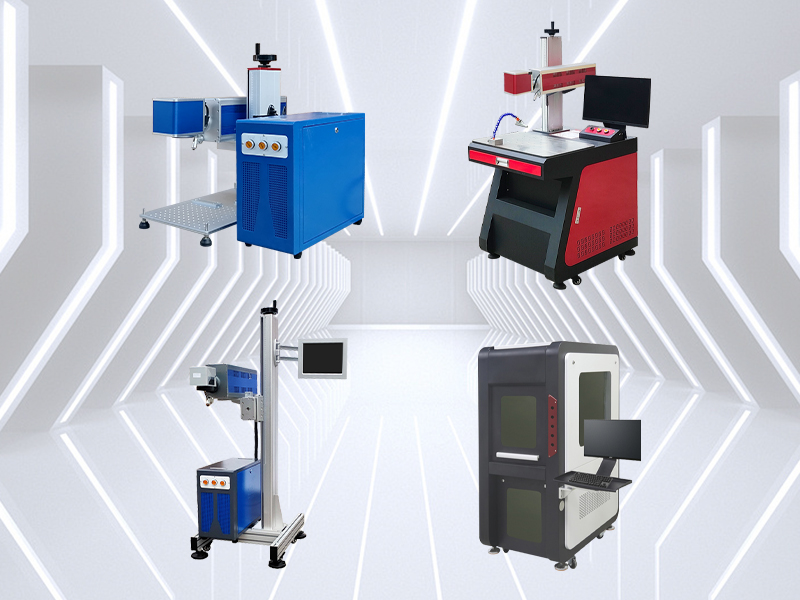

Recommended Products