Can Scribe Marking Machines Used in the Electronics Industry?

Precision, efficiency, and invention are key factors in the electronics industry. As electronic devices become smaller and more complicated, producers must use new techniques to meet demanding quality requirements. One such instrument is the scribe marking machine, which is a cutting-edge solution for precise marking and scribing. Let’s take a deep look at this.

What is Scribe Marking?

Scribe marking is a technique for leaving a permanent mark on a surface by engraving it with a marking needle. The scribe marking machine exerts pressure on the surface, leaving a visible, permanent depression that can be utilized for identification, tracking, or design reasons. Unlike typical engraving processes, scribe marking does not use heat, lasers, or chemicals; instead, it depends on mechanical force to make the marking, making it ideal for applications that require high precision and low distortion.

Principle of Scribe Marking Machines

Scribe marking machines employ a strong, durable stylus—typically made of diamond or tungsten carbide—that glides across a material’s surface to produce precise, permanent marks. Unlike laser engraving, which utilizes heat, scribe marking employs mechanical force, making it perfect for materials that are sensitive to heat or require high precision. The stylus gently engraves the material, creating a small, legible mark that causes no deformation or damage to the component.

The equipment is normally controlled automatically or manually, with the stylus following a preprogrammed path to make marks such as serial numbers, logos, or bar codes. This procedure enables clear, lasting identification even on hard metals, polymers, and other materials widely used in electronics.

Applications of Scribe Marking Machines in the Electronics Industry

Scribe marking machines have become an essential component of modern electronics manufacturing, providing remarkable precision and versatility. Their ability to leave clean, lasting traces on delicate and complex components makes them important in a wide range of industrial applications. Here are some of the major applications of scribe marking machines in electronics:

Scribe marking machines label printed circuit boards (PCBs) with serial numbers, barcodes, and component identifiers. These markers ensure traceability throughout the production process, facilitate assembly, and aid in quality control.

Microelectronics and Micro-Electro-Mechanical Systems (MEMS):

The small size of microelectronic components necessitates high precision. Scribe marking machines excel in this sector, as they provide the accuracy required to mark and identify microscopic items. This is critical to ensuring appropriate assembly and performance of devices such as sensors, actuators, and microchips.

Semiconductor Wafer Scribing:

In semiconductor manufacturing, scribe marking machines are used to create precise grooves on silicon wafers. These grooves guide the dicing and cutting processes, ensuring clean breaks and minimizing material waste. Additionally, scribe marks are used for wafer identification, enabling manufacturers to track each piece through the production line.

Consumer Electronics Branding:

From smartphones to laptops, consumer electronics require clear and durable branding. Scribe marking machines are used to engrave logos, regulatory markings, and product information onto devices and components. These marks not only enhance brand visibility but also ensure compliance with industry standards.

Flexible Electronics and Displays:

As flexible electronics and displays gain popularity, scribe marking machines are being used to mark and cut flexible substrates like polyimide films. This enables the production of innovative products such as foldable smartphones and wearable devices.

To summarize, scribe marking machines are critical to the electronics sector, allowing producers to attain the precision, traceability, and durability required in today’s fast-paced and innovative market. Their uses range from PCBs and semiconductors to consumer electronics, making them an essential tool in modern production.

Types of Scribe Marking Machines in Electronics

In the electronics industry, the type of scribe marking machine used is determined by the application’s specific requirements, such as the material being marked and the level of precision needed. The following are some of the most widely used types of scribe marking machines:

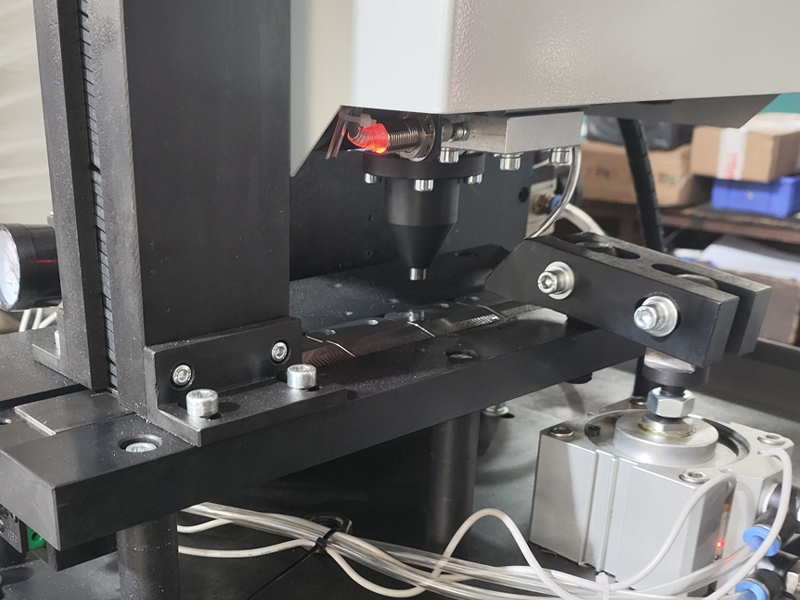

Pneumatic Scribe Marking Machines

Pneumatic machines use compressed air to drive the marking stylus across the material. These machines are known for their ability to mark tough materials like metals, ceramics, and even some plastics commonly found in electronics. Pneumatic scribe markers are favored in high-volume production environments due to their reliability and ability to handle hard, durable materials without causing damage.

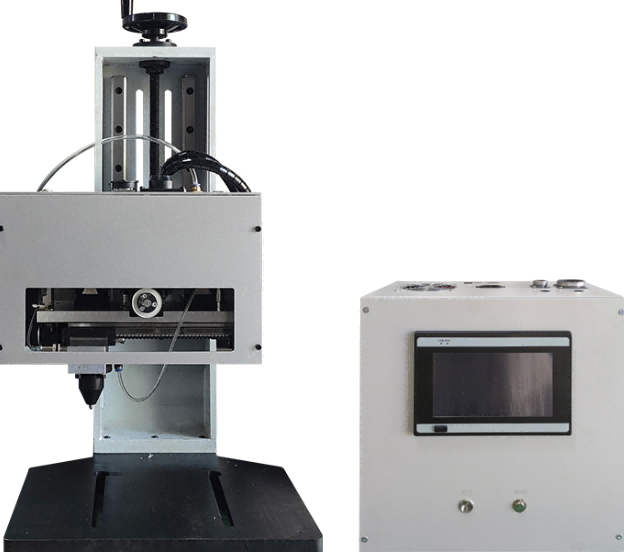

Electronic Scribe Marking Machines

Electric motors power electric scribe marking devices, which move the marking tool. These machines offer higher precision and control, making them suitable for applications that require detailed, high-quality markings. They are extensively used in electronics to label delicate components such as microchips, PCBs, and other small parts that require high accuracy. Electric machines are also more adaptable, allowing for faster and more consistent marking than pneumatic counterparts.

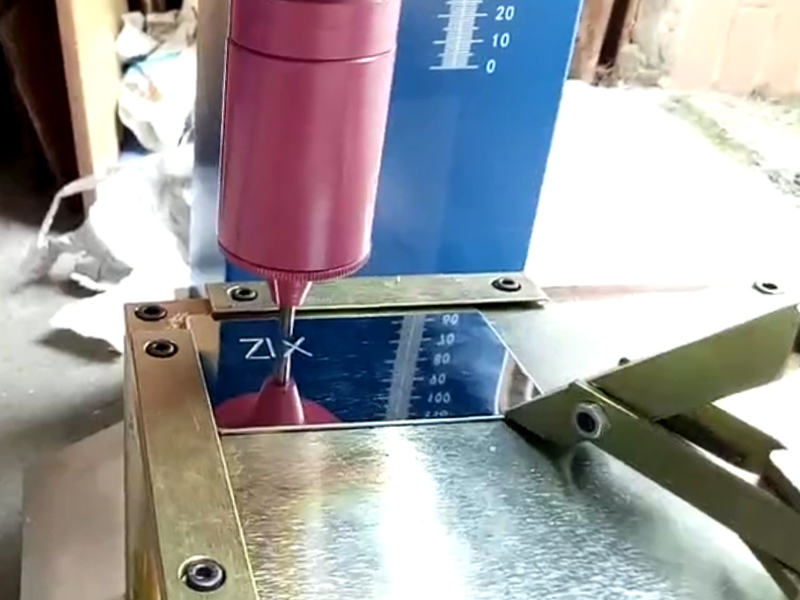

Manual Scribe Marking Machines

Manual scribe machines are operated by hand, offering flexibility and control over the marking process. While these machines are less common in large-scale production settings, they are still useful for smaller runs, prototypes, or custom jobs where precision and personalization are key. Manual machines are also a more affordable option for businesses that don’t need the high throughput provided by automatic models.

How to Choose the Best One?

When choosing a scribe marking machine for your electronics applications, consider the material being marked, precision requirements, and production size. Pneumatic machines are ideal for marking hard metals, but electric variants provide greater precision for small, delicate components such as microchips or PCBs. Manual machines are great for low-volume or specialized work, as they provide flexibility yet move at a slower rate. In addition, consider longevity, ease of maintenance, and cost-effectiveness. Understanding your individual marking needs—whether for high-volume manufacturing or small-scale projects—allows you to select the best machine to ensure efficiency and high-quality outcomes.

Summary

Scribe marking machines are important in the electronics sector, providing unparalleled precision, efficiency, and versatility. As the electronics industry evolves, scribe marking machines will remain an essential tool for fulfilling the needs of modern manufacturing. Whether you manufacture consumer electronics or complex semiconductors, investing in a scribe marking machine will lead to increased precision and success.

Ready to improve your electronics manufacturing process? Explore Zixu’s selection of scribe marking machines to find the ideal solution for your requirements. Contact us today for a consultation or to schedule a demo to see these devices in operation!

Recommended Products