CO2 vs. Fiber Laser Marking for Glass: Choosing the Right Technology for Your Needs

Of the many types of lasers available, CO2 lasers and fiber lasers are the two most commonly used in glass marking applications. Understanding the differences between these two technologies and how they are applied to glass is critical to choosing the right solution for your needs. This article will explore the key differences between CO2 laser and fiber laser marking, compare their performance for glass marking, and provide guidance for choosing the technology that best meets your needs.

Differences of CO2 and Fiber Laser Marking

CO2 and fiber lasers differ significantly in terms of their technology, wavelength, and application suitability. Understanding these differences is essential when choosing the right laser for marking glass.

CO2 Lasers

CO2 lasers are gas-powered lasers that utilize a carbon dioxide (CO2) gas mixture to generate laser light. They emit light at a wavelength of approximately 10.6 microns, which falls within the infrared (IR) spectrum. This longer wavelength enables CO2 lasers to interact efficiently with organic materials like wood, leather, plastics, and glass. Known for their versatility, CO2 lasers can produce high-quality markings across various materials, excelling at creating both deep engravings and intricate details, particularly on non-metallic surfaces such as glass.

Fiber Lasers

Fiber lasers, in contrast, are solid-state lasers that use a doped fiber optic cable (typically doped with ytterbium) to generate laser light. Fiber lasers emit light with a much shorter wavelength, around 1 micron, which is in the near-infrared spectrum. This shorter wavelength allows fiber lasers to achieve higher energy density and better focus. Fiber lasers are known for their exceptional precision, fast processing speeds, and excellent beam quality. While they excel at marking metals and reflective materials, they can also be used on glass, offering high-quality, precise markings, particularly in industrial applications.

Key Differences

| Feature | CO2 Laser | Fiber Laser |

| Wavelength | 10.6 microns (infrared spectrum) | 1 micron (near-infrared spectrum) |

| Material Suitability | Ideal for non-metals (glass, wood, plastics) | Best for metals and reflective materials, also effective on glass |

| Marking Style | Creates frosted, etched, and decorative designs | Produces sharp, fine markings, ideal for text and logos |

| Marking Depth | Can achieve deep engravings, but slower | Faster marking with fine detail, less deep engraving |

| Speed and Efficiency | Slower marking speed, more suited for intricate designs | Faster, higher precision, ideal for high-volume production |

| Cost and Maintenance | Generally lower initial cost, higher maintenance | Higher initial cost, lower maintenance, longer lifespan |

This table outlines the core differences to help determine which laser technology best fits your glass marking needs.

CO2 vs. Fiber Laser Marking for Glass

When selecting the right laser marking technology for glass, both CO2 and fiber lasers offer distinct advantages and drawbacks depending on the application.

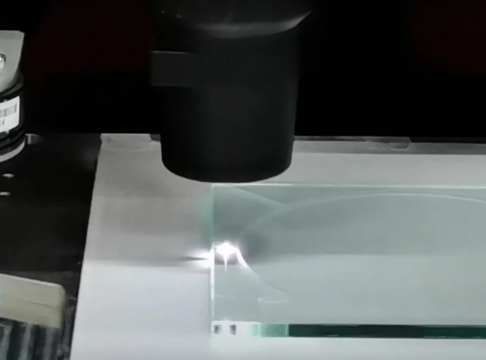

- CO2 lasers are commonly used for engraving and etching glass surfaces, producing highly visible marks with a frosted, white finish. This effect is perfect for decorative applications, such as branding or artistic designs on glassware. CO2 lasers are especially effective on flat glass surfaces, like bottles and windows, and can create deeper engravings with the proper settings. However, achieving the desired depth may require multiple passes or slower processing speeds.

- On the other hand, fiber lasers are known for their high precision and speed. With their shorter wavelength, fiber lasers can produce finer, sharper marks on glass, making them ideal for applications requiring small text or intricate patterns. Fiber lasers can also mark through coatings or surface layers, which is advantageous for certain industrial applications. However, they may not create the frosted or white appearance that CO2 lasers are known for, and they are less effective for deeper engravings.

| Feature | CO2 Laser | Fiber Laser |

| Marking Effect | Frosted, white marks | Fine, sharp marks |

| Precision | Moderate | High precision, ideal for fine details |

| Depth of Marking | Can create deep engravings, slower | Fast marking, but shallow engraving |

| Speed | Slower, requires multiple passes | Faster marking, more efficient |

| Ideal Applications | Decorative glass, branding, gifts | Industrial applications, small text, logos |

In summary, CO2 lasers excel in creating decorative and artistic marks, while fiber lasers offer precision and speed for industrial, fine-detail work. Choosing the right laser depends on the specific needs of the glass marking project.

How to Choose Between CO2 vs. Fiber Laser Marking for Glass?

When deciding between CO2 and fiber lasers for marking glass, there are a few key factors that can help you make the right choice based on your specific needs.

- Production Speed and Volume

If you’re working in a high-volume environment where speed matters, fiber lasers are usually faster than CO2 lasers. Their precision and high energy density allow them to mark faster, making them more efficient in mass production settings. On the other hand, CO2 lasers may be slightly slower, but they still offer excellent results for lower-volume, high-quality work, especially if you’re creating larger, more detailed designs.

- Marking Depth

CO2 lasers are ideal for creating deeper marks or engravings on glass, making them a great choice when a permanent, noticeable effect is needed. They are also excellent for achieving a frosted appearance on the glass surface, enhancing its visual appeal. However, if you don’t require depth and need precision for fine lines or intricate details, a fiber laser is the better option. While fiber lasers excel at surface-level markings, they are less effective at producing deep, frosted engravings.

- Type of Glass and Marking Style

Consider the type of glass you’re working with and the type of markings you need. CO2 lasers are excellent for decorative applications, creating smooth, frosted effects ideal for glassware, bottles, and custom engravings where appearance is important. On the other hand, if you need clean, fine details—such as serial numbers or small logos—on industrial glass, a fiber laser would be a better choice. Fiber lasers offer greater precision and can produce sharper, more detailed marks, making them perfect for small text or intricate patterns.

- Cost Considerations

When it comes to the upfront investment, CO2 lasers tend to be more affordable than fiber lasers. If you’re just starting out or have a limited budget, a CO2 laser might be a more cost-effective option. However, fiber lasers have a longer lifespan, require less maintenance, and often result in lower operating costs over time, making them a solid investment for businesses looking for longevity and minimal upkeep.

In summary, your choice should depend on the type of glass, the complexity of the design, your production volume, and your budget. CO2 lasers are well-suited for decorative, frosted designs and larger projects, while fiber lasers excel at precise, detailed work, particularly for smaller or industrial-scale applications. By considering these factors, you can select the right laser marking technology for your specific needs.

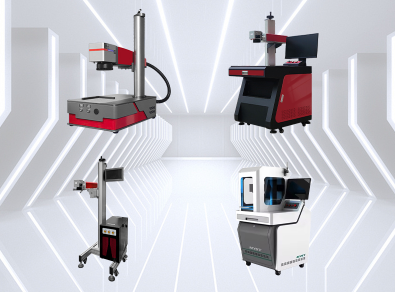

Need to Find Glass Laser Marking Machines for Glass?

If you’re looking for high-quality glass laser marking machines, Zixu is an excellent supplier offering a wide range of reliable solutions tailored to your specific needs. Whether you need to engrave intricate patterns on glass bottles, create permanent serial numbers on glass products, or achieve frosted effects for decorative items, Zixu has the right solution. Our advanced machines are known for their precision, speed, and versatility, making them ideal for both low and high-volume production.

Our team works closely with our customers to understand their marking needs and provide customized solutions that optimize both performance and cost efficiency.

Reach out to Zixu today to discover the perfect glass laser marking solution for your business.

Recommended Products