Common Five Mistakes to Avoid When Buying Marking Needles for Dot Peen Machines

Dot peen machines are essential instruments for making precise, permanent marks on diverse materials in the industrial marking and engraving industries. However, the performance of these devices is greatly dependent on the quality of their marking needles. Choosing the appropriate marking needle is critical for producing consistent results and extending the life of your equipment. In this post, we’ll look at why choosing the appropriate marking needle is important, what machines utilize them, what constitutes a good marking needle, and the top five mistakes to avoid when purchasing marking needles for dot peen machines.

Why Choosing the Right Marking Needle Matters

The marking needle is the primary contact between your machine and the material being marked, and its performance directly impacts the accuracy of your markings. Selecting a needle with the wrong material, size, or design can result in frequent breakdowns, poor-quality marks, and costly downtime. By making informed decisions, you can optimize productivity, reduce maintenance costs, and improve the overall performance of your dot peen system.

What Machines Use Marking Needles?

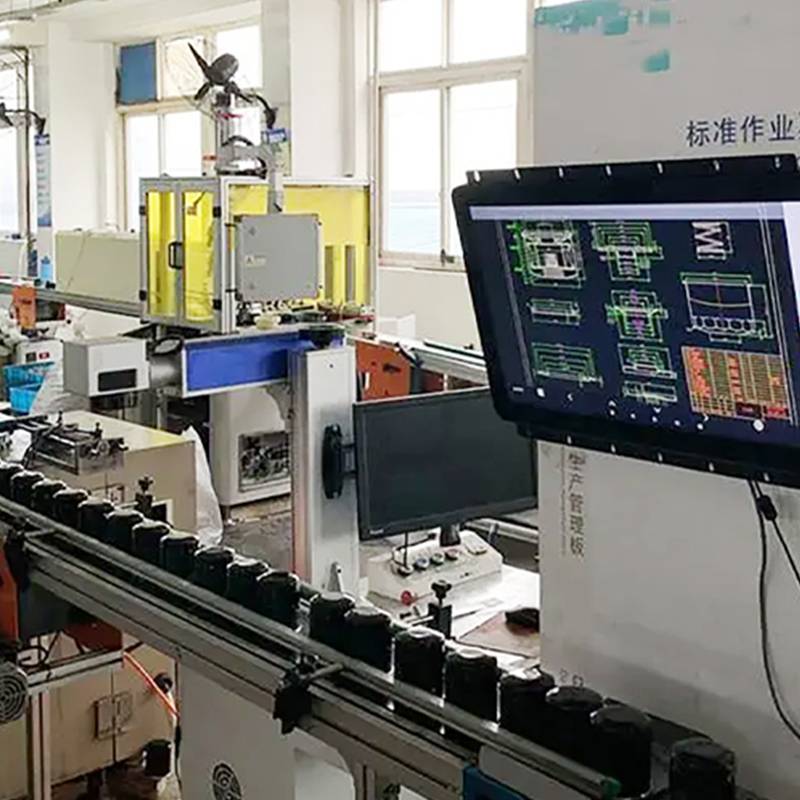

Marking needles are specifically intended for dot peen marking machines, which are commonly used in industries such as automotive, aerospace, electronics, and manufacturing. These machines use a pneumatic or electric drive mechanism to strike the marking needle on the surface of the workpiece, resulting in a series of dots that form letters, numbers, logos, or other designs.

Different types of dot peen machines use various marking needles depending on their operation type and application. For instance:

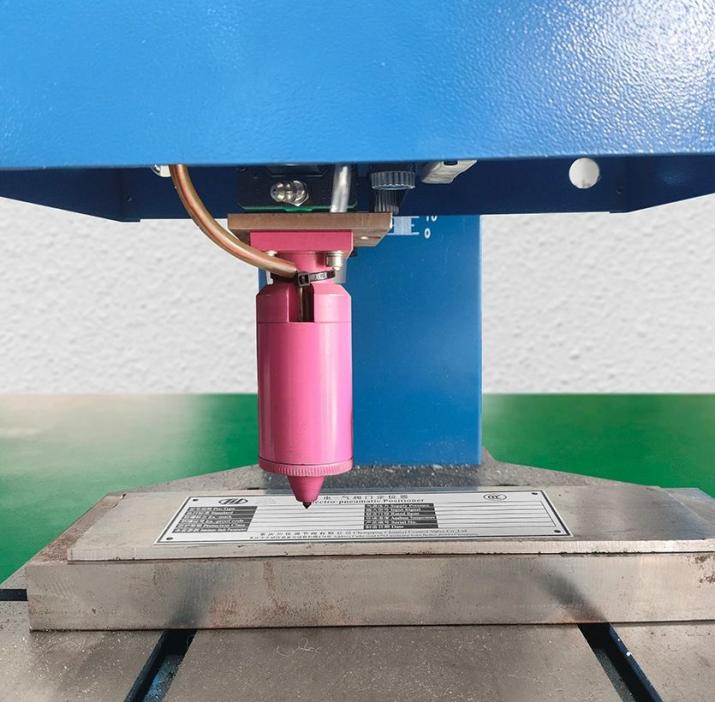

- Pneumatic Dot Peen Machines: These machines are powered by compressed air and require high-quality, durable needles capable of withstanding repeated impacts.

- Electric Dot Peen Machines: These operate via an electric drive system, often requiring specialized needles designed for efficient energy transfer and precise markings.

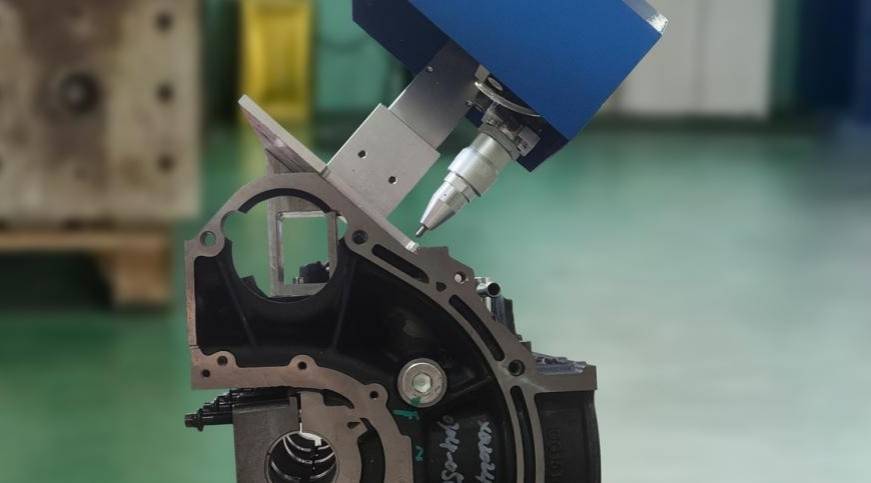

- Scribe Marking Machines: These machines utilize a sharp stylus to create markings by scratching or engraving the material’s surface. They often require highly precise and durable styluses, engineered to maintain sharpness and withstand the friction and pressure involved in the scribing process.

What is a Good Marking Needle?

A good marking needle should meet several key criteria to ensure consistent, high-quality performance:

- Material Strength: A high-quality marking needle is often composed of durable materials such as tungsten carbide, which is resistant to wear. This guarantees that the needle lasts longer and can withstand high-frequency strikes without degrading too rapidly.

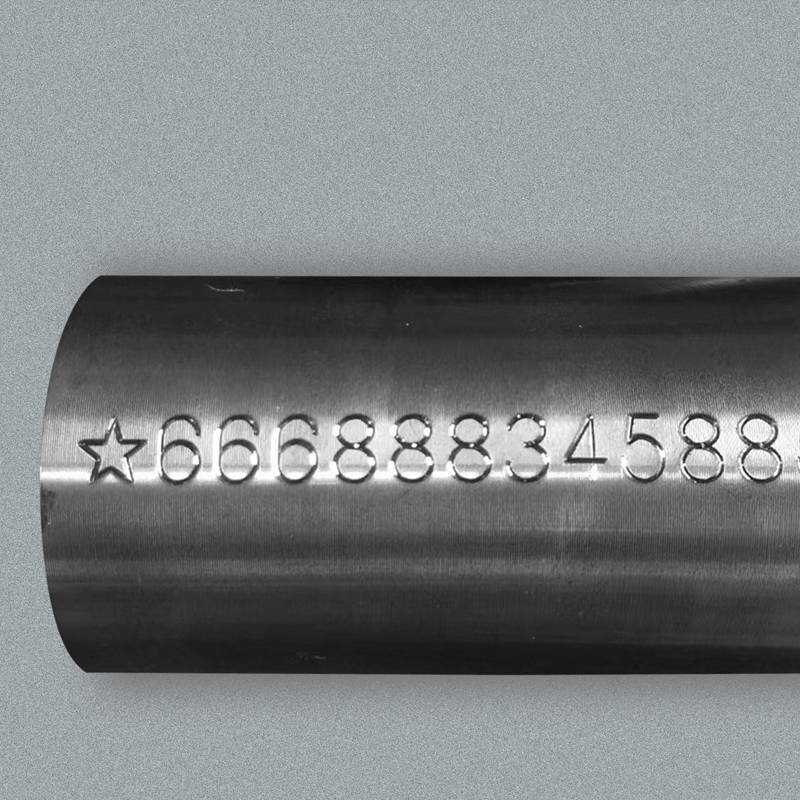

- Precision: The needle must be able to create clear, crisp, and precise marks. Whether you’re engraving delicate details or deep, legible serial numbers, the needle should consistently create high-quality results.

- Compatibility: Not all needles are made equal, so it’s important to choose a needle that’s compatible with your dot peen machine’s specifications, such as diameter, length, and mounting design. Using the right needle prevents damage to both the machine and the material you’re marking.

- Durability: A good needle not only survives, but flourishes under duress. Look for needles that can withstand high-speed impacts and intense marking sessions, as this reduces downtime and replacement expenses.

Essentially, a good marking needle ensures precision, reliability, and longevity, all while helping your dot peen machine perform at its best.

Common Five Mistakes to Avoid When Buying Marking Needles

Marking needle marking effect

When purchasing marking needles for dot peen machines, avoiding common pitfalls can save you time, money, and frustration. Here are five mistakes to watch out for:

1. Ignoring material compatibility.

Using a needle made for soft materials on a hard metal, or vice versa, produces unsatisfactory results. Incompatible needles can easily break, leave faint or uneven traces, and possibly damage your machine. Always use needles made precisely for the substance you’re marking, whether it’s soft plastic, aluminum, or harder steel.

2. Overlooking Needle Tip Geometry

The form and size of the needle tip influence the quality of the mark. A misaligned tip can result in confusing or irregular markings. For example, a conical tip is best for deep, precise marks, whereas a flat tip is preferable for shallow, wide imprints. Choose the tip geometry that best meets your marking requirements.

3. Prioritizing Price Over Quality

Opting for cheaper needles might seem like a cost-saving move, but it often backfires. Low-quality needles wear out quickly, leading to frequent replacements, increased downtime, and higher long-term costs. Investing in high-quality needles from reputable suppliers ensures durability and consistent performance.

4. Neglecting Machine Compatibility

Not all marking needles are universal. Using needles that aren’t compatible with your dot peen machine can cause operational issues or even damage the machine. Always verify that the needles you purchase are designed for your specific machine model.

5. Neglecting to consider marking depth and speed

Marking depths and speeds vary depending on the application. Using a needle that cannot manage the necessary depth or speed can result in faint, incomplete marks or extremely deep, deformed ones. Make sure the needles you purchase are capable of meeting your unique marking requirements.

By avoiding these mistakes, you can ensure that your dot peen machine runs smoothly, generates high-quality results, and is cost-effective in the long term. Always prioritize quality, compatibility, and adaptability to your individual requirements.

Make the Right Choice for Marking Needles

Choosing the correct marking needle for your dot peen machine is an important decision that will effect the quality of your markings, the efficiency of your operations, and the longevity of your equipment. Avoiding the frequent mistakes listed above will guarantee that you invest in needles that provide precision, durability, and value for your individual application.

When it comes to reliable and high-quality marking needles, Zixu stands out as a trusted manufacturer. Specializing in the production of durable and precision-engineered marking needles, Zixu offers a wide range of options designed to meet the demands of various industries. Our needles are crafted from high-grade materials like carbide and tungsten carbide, ensuring exceptional wear resistance and longevity. Whether you’re marking soft plastics or hard metals, Zixu provides needles that deliver consistent, high-quality results. Contact us now for any needs!

Recommended Products