Construction & House Finishing

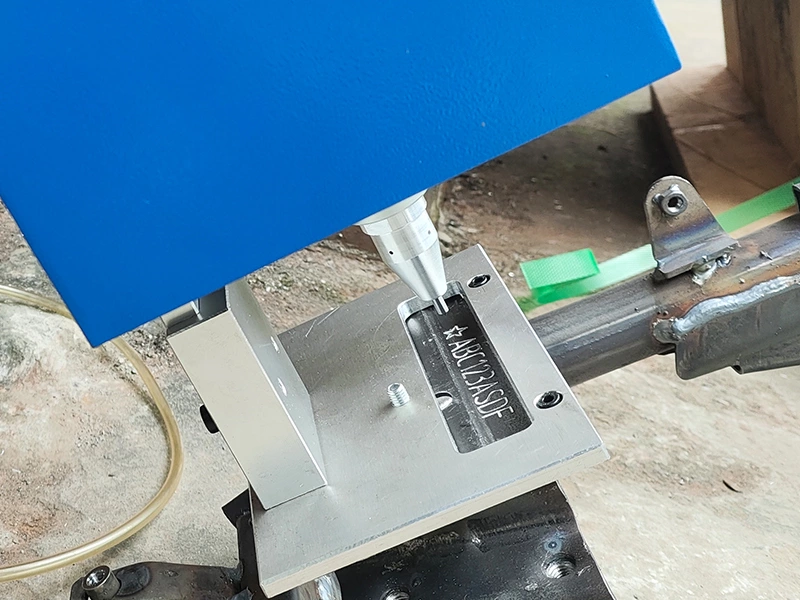

Today’s construction and house finishing industries uses numerous standardized and non-standardized metal parts that require direct part marking (DPM), from metal profiles to pipes and fasteners. The identification and traceability of these critical metal parts is critical to the quality and longevity of the work, and many manufacturers use cost-effective, rapid blast marking to identify these parts.

Technologies For Construction & House Finishing

The construction and house finishing industries use a wide variety of standardized and non-standardized metal parts, ranging from metal profiles to pipes and fasteners that are used in large quantities, especially structural steel. The identification and traceability of these critical metal parts is critical to the quality and longevity of the work, and many of these manufacturers use cost-effective and fast peen markers to mark the parts.

- Fast: to mark with same specific depth such as 0.3mm, our peen marking machine is 8~10X faster than a 100W fiber laser system;

- Depth: our peen marking machine offer 0.1~0.3mm depth in one pass, and able to precise repeat for deeper marks;

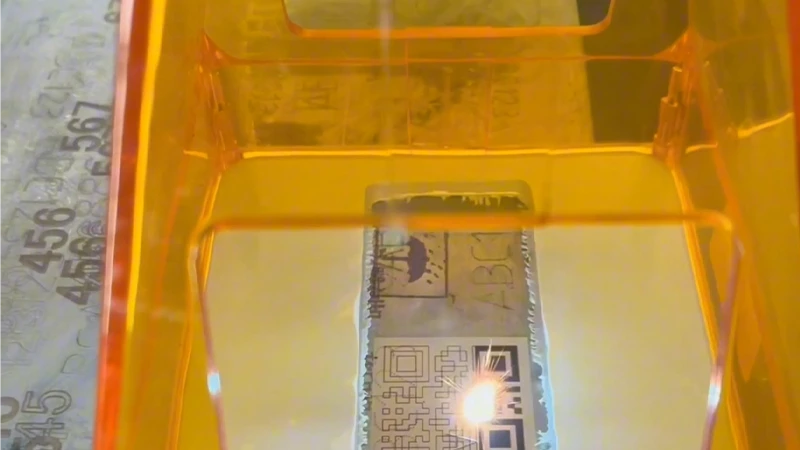

- Traceability: in addition to serial numbers or date marks, our peen markers can mark scannable DPM or QR codes for digital management.

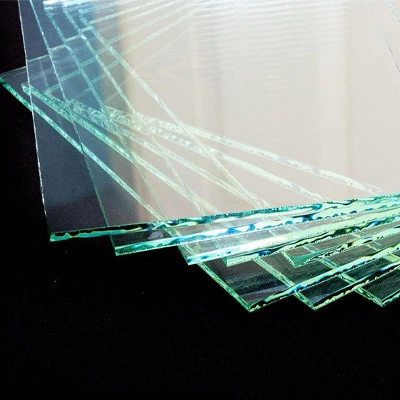

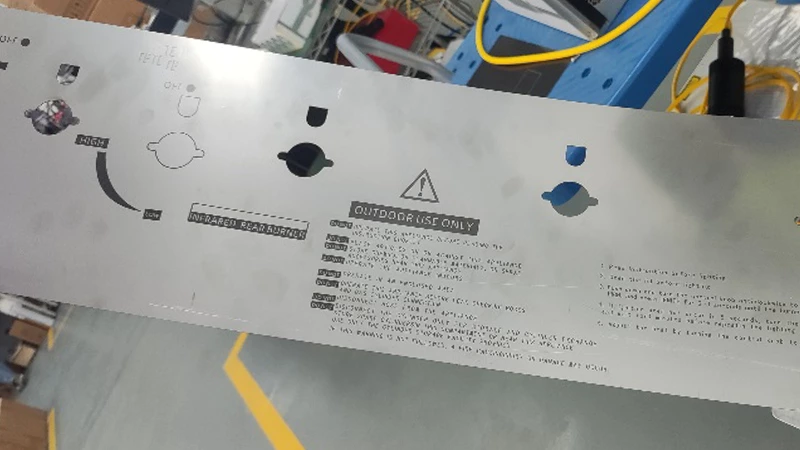

In fact, the more dominant technology for direct part marking (DPM) is the use of lasers, especially for smaller metal parts and other non-metallic materials such as screws, PVC pipe, wire, glass, etc. In addition, laser marking can be used to create easy-to-read warning labels. In addition, laser marking can be used to create easy-to-read signs for electrical systems, escape route lights, etc.

- Quiet: laser marking of metal also generates noise especially deep engraving, but this is negligible compared to the peen marking process;

- Accuracy: Laser marking can mark metal in extremely small size, such as 2*2mm square UDI code or 0.03mm line width characters, which are impossible for peen marking;

- Visibility: Using MOPA fiber or UV laser for laser annealing instead of engraving for black or other color marking on metal workpiece with high contrast.

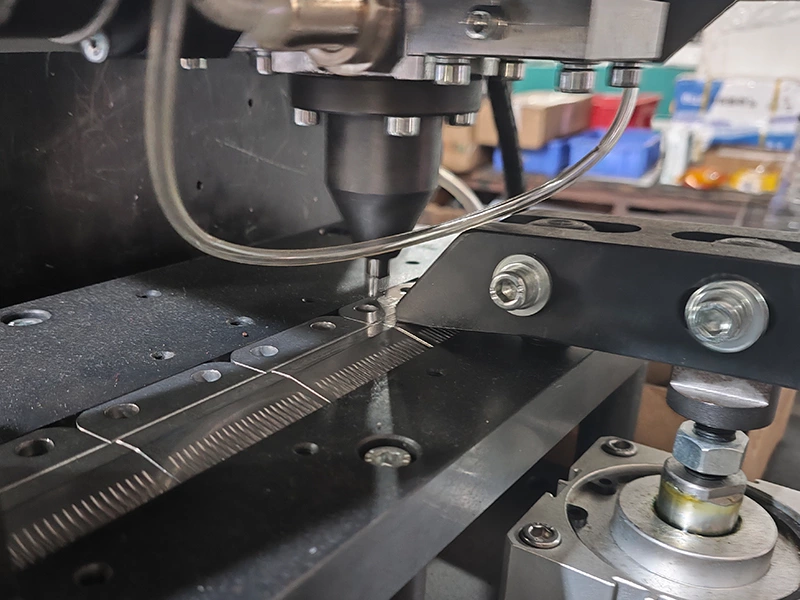

From pre-engineered steel structures to metal roofing and curtain walling, from pipes to windows, doors and fences, all can benefit from efficient laser welding. Laser welding is much more efficient than conventional TIG, MIG or MAG welding, allowing you to complete jobs quickly, while providing consistent and reliable weld depths and strengths, allowing you to provide excellent service to your customers.

- Easy to use: extremely consistent weld quality that requires less operator skill than TIG and MIG welding;

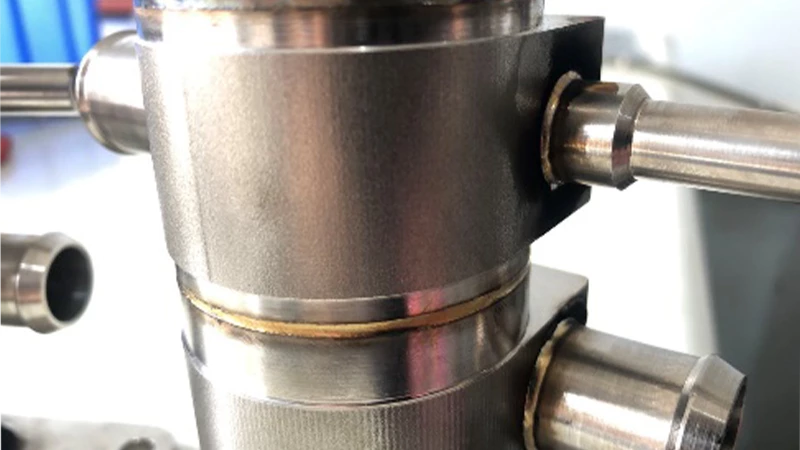

- Precise: QCW or MOPA fiber laser welding system produces extremely small spots and weld marks for high-precision welding of thin sheets, films, electronic circuits and more;

- Easy to automate: the physical structure of laser welding is simpler than that of TIG and MIG, which facilitates the development and use of automated welding.

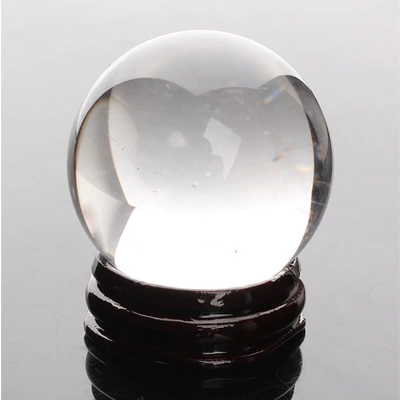

Unlike other industries, only state-of-the-art pulsed laser cleaning technology is commonly used and recognized in these industries. Because pulsed laser cleaning is virtually non-destructive to most stone, glass and wood, it can be used to efficiently and non-destructively remove dust, dirt, metal rust and old paint from historic stone and wood buildings as well as the glass exteriors of modern buildings or concrete structures.

- Efficiency: the high-energy laser beam vaporizes contaminants in a very short time with minimal damage to the workpiece.

- Non-consumable: laser cleaning can be operated without detergents or catalysts, a significant savings for high-volume industrial metal derusting.

- Non-contact: laser beam can remove rust, oxides, oil, grease, paint and coating at a distance, therefore suitable to clean hard-to-touch workpiece such as injection mold.

Explore Our Machines For Construction & House Finishing

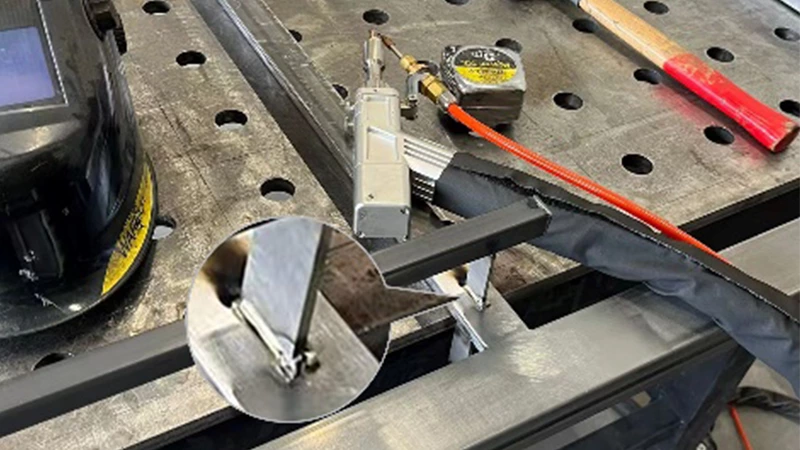

In the field of construction and finishing, the application of peen marking is mainly focused on the marking of construction metal profiles, finishing materials, pipes and fittings, as well as the marking of related components, mainly the production batch number, production date or installation date. We offer reliable peen markers for marking large quantities of profiles as well as for portable marking at the installation site.

In fact, the dominant technology for direct part marking (DPM) is the use of lasers, especially for smaller metal parts and other non-metallic materials such as screws, PVC pipe, wire, glass, and so on. In addition, laser marking can be used to create easy-to-read warning labels. In addition to desktop and stand-alone machines, we also have a wide range of portable laser marking machines that allow our customers to work anywhere, anytime.

In addition to parts marking similar to peen marking, lasers in this industry can also cover custom logos, pattern printing and engraving. Whether it’s marking on all types of metal and PVC tubing, decorative glass and wood, 3D engraving on metal, wood, ceramics or stone, we have the solution. We recommend consultation to obtain the optimum configuration based on the material and the actual application.

In addition to decorative material patterns, functional signage is essential in buildings. From room identification to electrical warning signs, from asset tags on fixtures to the numbering of pipes or small appliances, high-contrast markings can be achieved with lasers. Instead of purchasing off-the-shelf signage, custom markings created by paint stripping with a small portable laser allow for flexible deployment to meet real-world needs.

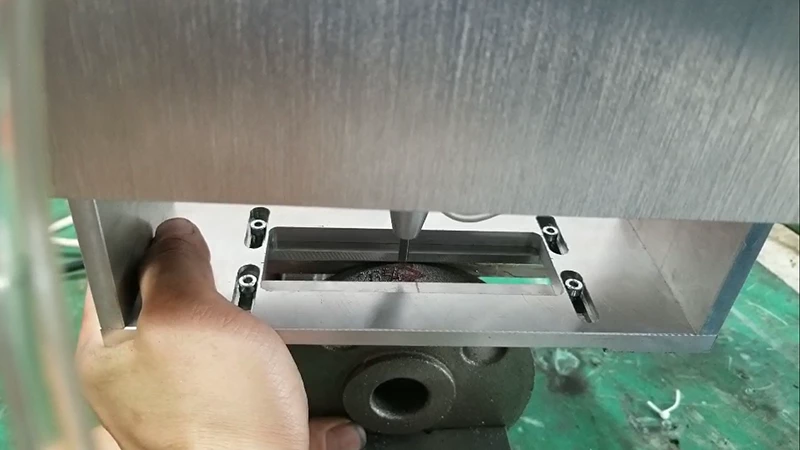

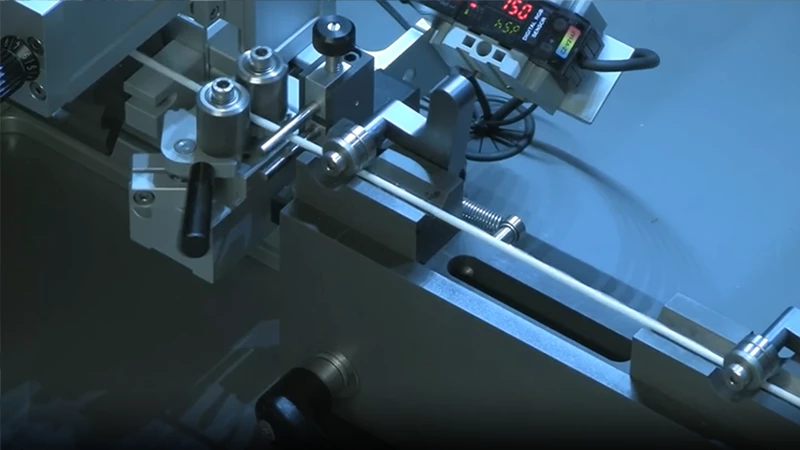

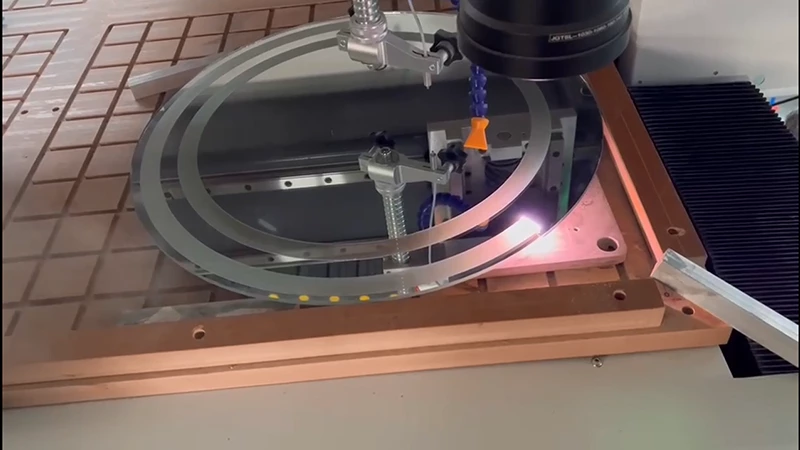

Some manufacturers of prefabricated steel structures and various types of pipes and valves are using automated platform laser welding to reduce the risk of manual welding in complex shapes and small work areas, and to achieve deeper welds with high power lasers. In addition, some construction companies use automated laser welding machines or even welding robots to construct steel buildings or buildings with large openings, such as stadiums, shopping malls, railway station, airport and hospitals.

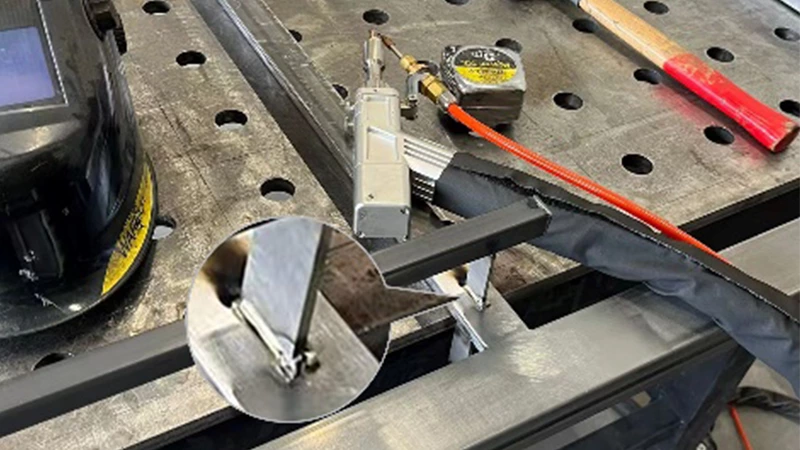

More common, of course, is the relatively inexpensive and simple handheld laser welder. Whether it is a metal roof or curtain wall during construction or a metal fence, door or window during finishing, the handheld laser welder can be used to weld quickly, easily, beautifully and safely. Compared to TIG, the handheld laser welder provides faster, more uniform weld scars and eliminates the need for post-polishing.

Laser cleaning has been used since the 1970s to clean heritage and historic buildings. The use of a specific 1064nm laser wavelength in combination with the right frequency and pulse width allows the efficient removal of rust, oxidation, old paint or other contaminants without damaging materials such as stone, wood, steel, concrete or brass.

Due to the unavoidable presence of grease and oil in many of the manufacturing processes of metal construction raw materials, and the high susceptibility of these materials to corrosion and oxidized films during long-term storage, laser cleaning has become an excellent alternative to chemical cleaners in the face of environmental regulations that limit the range of chemical cleaners that can be used.

In addition, similar to laser welding, the use of laser cleaning is becoming increasingly popular for the maintenance of large-span metal structures in large buildings. Whether it is laser ablating old coatings for repainting or removing rust and oxides from bare metal surfaces for repainting or repair welding, large bridges, hotels, hospitals, train stations, airports, sports fields and other buildings are benefiting from the use of laser cleaning.

Want an un art handing video demonstration on specialized material? Looking for a solution to your specialized environment or automatic process demand?