Dot Peen Marking: Handheld vs. Benchtop

Dot peen marking is an industrial method for producing permanent, high-precision marks on various materials. Ideal for engraving serial numbers, barcodes, logos and other identifiers onto serialized items – dot peen marking machines offer durability and efficiency!

In this blog, we’ll compare handheld versus benchtop dot peen marking machines so you can select the appropriate option for your application.

What is Dot Peen Marking?

Dot peen marking is an industrial marking process that employs a carbide or diamond-tipped stylus to leave permanent indents on materials’ surfaces. By rapidly striking the workpiece with this stylus, a series of closely spaced dots forms into alphanumeric codes, logos, serial numbers, barcodes or 2D data matrices; making dot peen marking perfect for industries needing long-lasting identification marks that withstand heat, corrosion and abrasion environments.

Dot peen marking is a versatile marking technique widely utilized on metals (steel, aluminum and titanium), plastics and composites. Unlike laser marking, dot peen does not rely on heat or chemicals – providing an economical, low maintenance solution to part tracking, compliance monitoring and branding needs.

Types of Dot Peen Marking Machine

Dot peen engraving machines typically feature either pneumatic or electric designs and use interchangeable marking pins that quickly modify their work mechanism according to user needs. Dot peen engravers tend to operate slowly when marking delicate materials while operating faster when marking hard surfaces such as stone surfaces.

Manufacturing industries frequently utilize this machine when marking products permanently for various standards or regulations in their field, rather than printed labels. Extra durable forms of marking such as handstamps or Etching pens may result in lower quality markings than this machine does.

Electric Dot Peen Marking Machines

Electric dot peen marking machines use an electromagnetic solenoid to drive the stylus. This design eliminates the need for compressed air, making it an excellent choice for environments where simplicity, portability, and low maintenance are priorities. These machines are especially well-suited for indoor, office-like settings or facilities where access to an air compressor is limited.

Advantages of electric models include:

- Easy to set up and operate

- Lower operating costs (no air supply needed)

- Quieter operation compared to pneumatic systems

- Ideal for lightweight and portable applications

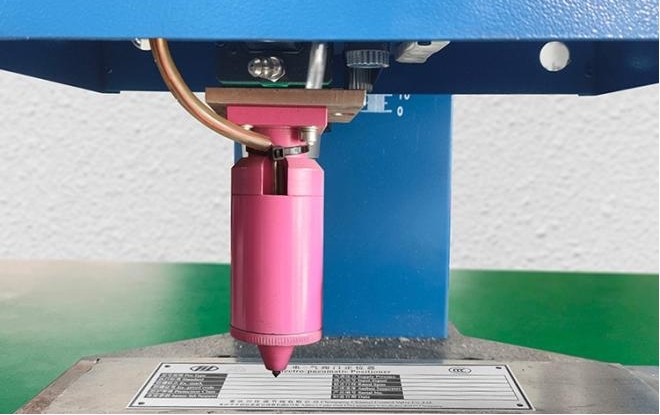

Pneumatic Dot Peen Marking Machines

Pneumatic dot peen marking machines employ compressed air to drive their stylus with greater force, creating deeper and quicker marking. These heavy-duty industrial marking machines are often found in heavy industries where durability, speed and depth of marking is of the utmost importance – such as automotive, aerospace or metal fabrication industries.

Advantages of pneumatic models may include:

- Rapid Marking Speed and greater

- Mark Depth on Hard Materials

- Production environments that need high volume capacity production.

- Reliable performance in harsh environments

Handheld vs. Benchtop Variations

Based on portability, both electric and pneumatic systems usually come in handheld (portable) and benchtop (stationary) versions.

- Handheld models emphasize portability and flexibility, making them the perfect solution for marking large, heavy, or irregularly shaped workpieces directly on the factory floor. Pneumatic versions provide extra durability in harsh industrial settings, while electric options may offer quieter operation when marking lighter materials.

- Benchtop machines excel in precision and automation, such as electric benchtop markers for intricate engraving on small parts or pneumatic benchtop systems for rapid deep marking on production lines. Selecting between them depends upon your workspace requirements, material needs, and production volumes.

What is Handheld Dot Peen Marking Machine?

Handheld dot peen marking machines are compact, portable engraving devices designed for on-site permanent marking. Utilizing either pneumatically or electrically driven styli to mark metal, plastic, and other hard surfaces permanently with permanent indents is ideal when large, heavy, or irregularly-shaped workpieces cannot be moved easily to a stationary workstation workbench.

Operators simply position a handheld unit against material, and its carbide pin rapidly strikes it to form dots that combine into alphanumeric codes, logos, barcodes, or Data Matrix symbols. Many modern handhelds feature adjustable depth control features as well as LCD interfaces and Bluetooth connectivity to integrate smoothly into production systems.

Key Advantages of Handheld Dot Peen Marking Machine

- Mobility – cost-effectiveness, and Portability are among the many key attributes associated with handheld models that make them great choices. (These can be utilized across factory floors, warehouses, and even outdoor job sites.

- Quick Setup – No fixtures are needed; all that’s required to set up is positioning and marking the objects.

- Flexibility – Able to handle complex parts that benchtop machines cannot.

- Cost-Efficiency – Lower upfront costs than benchtop systems with minimal ongoing costs associated with maintenance requirements and servicing requirements.

Due to their versatility and ease of use, handheld dot-peen markers have become ubiquitous across the automotive, aerospace, and heavy machinery industries. If your workflow demands versatility and user convenience, handheld models may provide just what is needed.

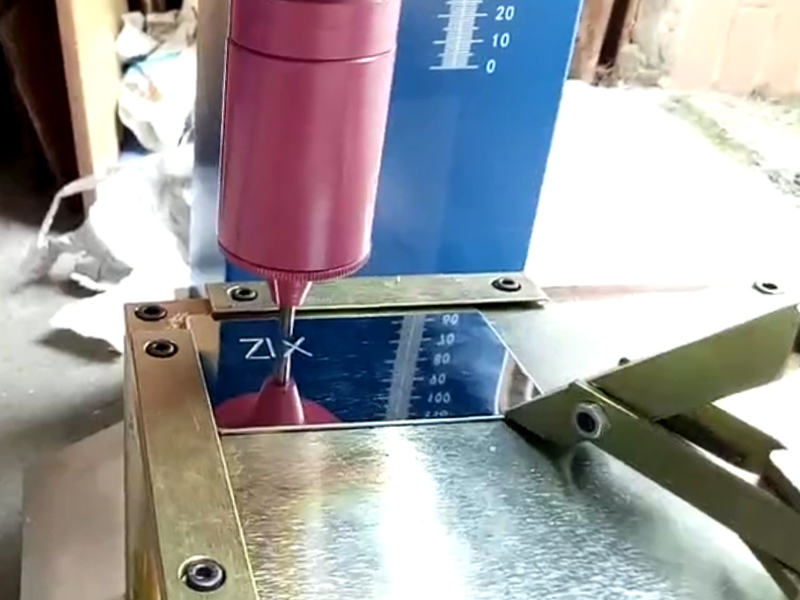

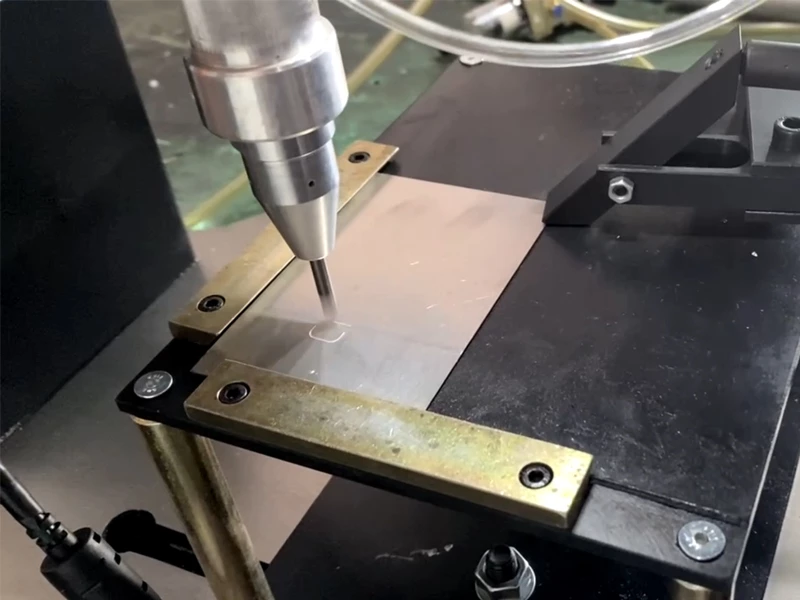

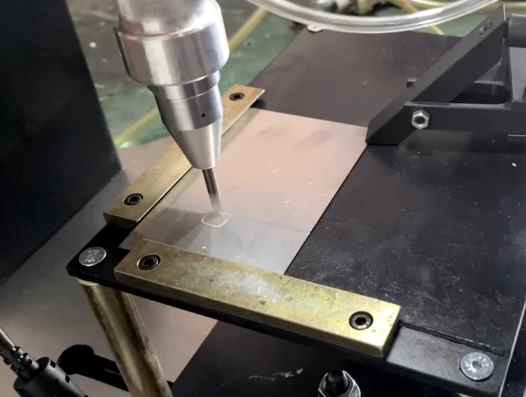

What is a Benchtop Dot Peen Marking Machine?

A benchtop dot peen marking machine is a stationary, high-precision engraving system designed for controlled industrial environments. Unlike handheld models, it is mounted on a workbench or integrated into production lines, offering superior accuracy and repeatability. This type of machine is ideal for applications requiring consistent, high-quality marks on smaller or medium-sized workpieces.

Key Features & Advantages of Benchtop Dot Peen Engraver

- Precision– Perfect for fine details with tight tolerances.

- Stable Performance– Reducing operator influence for uniform marks.

- Automation Ready – Compatible with robotic arms and conveyor systems.

- High-Speed Marking – High speed marking can provide efficient batch production with minimal downtime.

This type of machine is ideal for:

- Electronics, medical tools, and jewelry

- High volume production (automotive components and aerospace)

- Controlled environments (laboratories or factories with stringent quality standards) offer greater levels of quality assurance than unrestrained ones (labs).

Ideally suited to applications requiring consistent, high-quality marks with minimum manual intervention, benchtop dot peen markers provide reliable marks.

Handheld vs. Benchtop Dot Peen Marking Machine

Selecting between handheld and benchtop dot peen marking machines depends on your specific requirements for workpiece size, precision needs, production volume and other aspects. Here is a detailed comparison between them that should help make your decision easier:

| Feature | Handheld Dot Peen Marker | Benchtop Dot Peen Marker |

| Portability | Highly portable – can be used anywhere | Fixed in one location |

| Precision | Good for general markings | High precision for fine details |

| Workpiece Size | Best for large, heavy, or irregularly shaped parts | Ideal for small to medium-sized parts |

| Automation | Manual operation only | Can integrate with CNC, robotics, or conveyor systems |

| Marking Speed | Slower (depends on operator) | Faster (consistent, automated marking) |

| Ease of Use | Simple setup, minimal training | Requires initial setup but offers repeatability |

| Cost | Lower upfront cost | Higher initial investment |

| Best For | Field marking, maintenance, large components | High-volume production, detailed engravings |

In a word:

Choose Handheld if you need flexibility, work with large parts, or have a limited budget.

Choose Benchtop if you require high precision, automation, or fast batch marking.

Get The Best Dot Peen Engraver Fit Your Needs

When selecting a dot peen engraver, consider Zixu, a leading manufacturer based in China since 2006. Zixu offers a comprehensive range of dot peen marking machines, including handheld and benchtop models, tailored to various industrial applications.

Our products are renowned for reliability and efficiency, serving Fortune 500 companies across automotive, electronics, and manufacturing sectors. With over 20 models and customizable solutions, Zixu ensures precise and durable markings on diverse materials.

Explore our offerings at cnmarking.com to find the perfect dot peen engraver for your needs

Recommended Products