Dot Peen Marking vs. Laser Marking: Which is Suitable for Your Application?

Dot peen marking and laser marking are two of the most widely used permanent marking technologies in industrial and manufacturing applications. Both strategies have distinct advantages, but which one you choose is determined by your specific requirements. In this post, we’ll look at the distinctions between dot peen marking and laser marking, as well as how to pick which is ideal for your specific application.

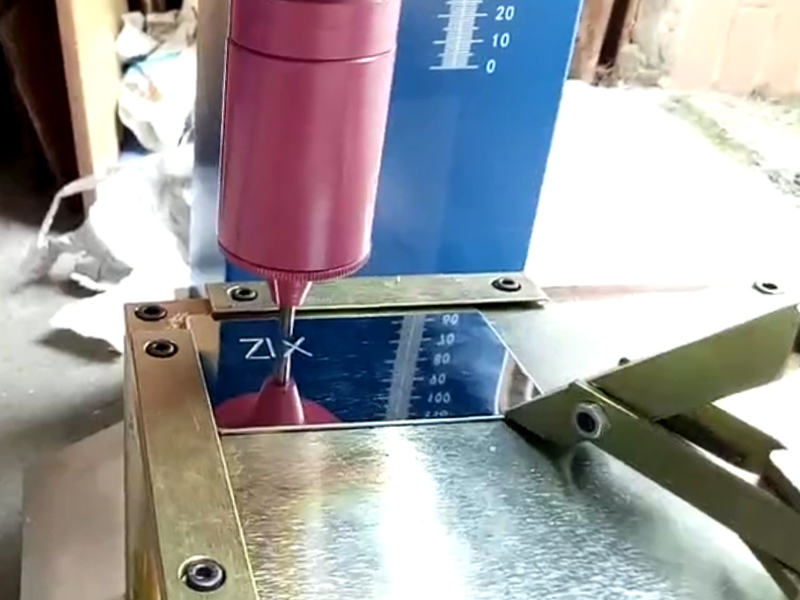

What is Dot Peen Marking?

Dot peen marking, also known as dot marking or pin marking, is a mechanical marking technique that employs a stylus to leave permanent indentations on a surface. The stylus, usually composed of carbide or diamond, moves quickly up and down, striking the material to produce a succession of dots. These dots combine to form alphanumeric codes, serial numbers, logos, and other designs. This approach is commonly employed in industries that require long-lasting marks, such as automotive, aerospace, and manufacturing.

Dot peen marking is highly durable, making it excellent for use in severe areas where marks must endure abrasion, heat, or chemical exposure. It is also a less expensive solution than laser branding. Furthermore, it works well on uneven or rough surfaces, making it suitable for a variety of materials such as metals, plastics, and composites. However, it may not be appropriate for applications that need delicate details or high-speed marking. Overall, dot peen marking is a dependable option for strong, permanent identification.

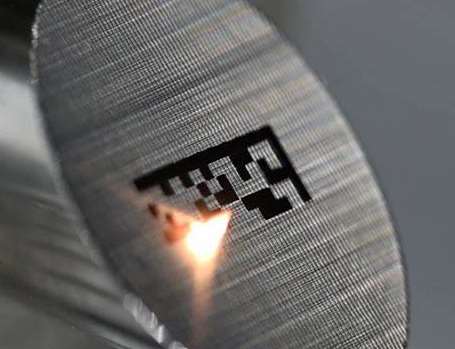

What is Laser Marking?

Laser marking is a cutting-edge, non-contact marking technique that use a concentrated laser beam to leave permanent traces on a material’s surface. The procedure alters the material’s characteristics using heat, resulting in changes such as color contrast, engraving, or surface etching. This technology is extremely accurate and is commonly utilized in industries that require detailed, high-quality markings, such as electronics, medical devices, and automotive manufacture.

The key features of laser marking include:

- Precision: Delivers exceptionally fine and intricate marks, ideal for small or complex designs.

- Speed: Operates quickly, making it suitable for high-volume production lines.

- Non-Contact Process: Eliminates physical contact with the material, reducing the risk of damage or deformation.

- Versatility: Effective on a wide range of materials, including metals, plastics, glass, ceramics, and even organic surfaces.

- Permanence: Produces long-lasting marks resistant to fading, wear, and environmental factors.

Laser marking is particularly valued for its ability to create high-contrast, readable marks without compromising the integrity of the material. Its flexibility and precision make it a top choice for applications demanding accuracy and aesthetic appeal.

Key Differences Between Dot Peen Marking and Laser Marking

To determine which marking method is best for your application, it’s important to understand the key differences between dot peen marking and laser marking. Here is a table summarizing the key differences you must notice.

| Factor | Dot Peen Marking | Laser Marking |

| Technology | Uses a stylus to create indentations on the surface | Uses a laser beam to modify the material’s surface |

| Marking Speed | Slower, as it relies on mechanical impact | Faster, especially for complex designs |

| Versatility | Works well on uneven and curved surfaces | Best for flat surfaces and intricate designs |

| Mark Quality | Produces deep, permanent, but less precise marks | Creates high-contrast, precise, and detailed marks |

| Material Compatibility | Suitable for metals, some plastics, and ceramics | Works on metals, plastics, glass, ceramics, and more |

| Maintenance | Requires regular stylus replacement due to wear | Minimal maintenance with no physical contact |

| Noise Level | Noisy due to mechanical impact | Silent operation |

| Initial Cost | Lower initial investment | Higher upfront cost |

| Operational Cost | Higher due to wear and tear | Lower in the long run with minimal maintenance |

This comparison should help in selecting the right marking method based on your specific needs.

Best Application of Dot Peen Marking & Laser Marking

Choosing the right marking technology also depends on the industry, material type, and specific application requirements. Here’s a breakdown of the best use cases for dot peen marking and laser marking:

Best Applications of Dot Peen Marking

Dot peen marking is perfect for industries that demand deep, long-lasting, and permanent markings, particularly on metals and hard surfaces. Because it physically indents the surface, it is extremely resistant to wear and environmental factors. Some of its main applications are:

- Automotive Industry – Used to label VIN numbers, engine parts, and metal nameplates to provide traceability throughout the vehicle’s lifetime.

- Aerospace industry – Permanent marking is required for aircraft components, turbine blades, and structural sections to ensure compliance and safety.

- Heavy Machinery & Tools – Used for serial numbers, part identification, and equipment tracking, particularly on industrial-grade machinery and tools that must withstand tough circumstances.

- Metal Fabrication & Manufacturing – Typically used for stamping parts, pipelines, and welded assemblies, with consistent marks even on rough or coated surfaces.

Best Applications of Laser Marking

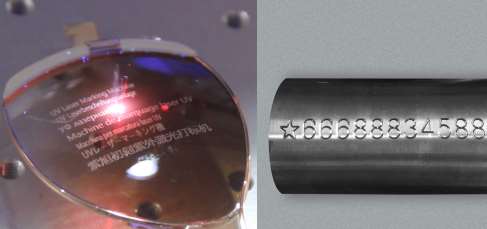

Laser marking is preferred for applications that require high precision, speed, and non-contact marking. It excels in producing detailed, high-contrast marks on various materials, including metals, plastics, and ceramics. Key applications include:

- Medical Devices and Pharmaceuticals – Used to ensure that surgical tools, implants, and medical packages comply with tight identification and tracking rules.

- Electronics and Semiconductor Industry – Ideal for circuit board etching, microchips, and barcodes that require precise and non-damaging branding.

- Jewelry and Luxury Goods – Engraves elaborate designs, serial numbers, and personalization on metals, timepieces, and glass without hurting the surface.

- Food, beverage, and packaging – Typically used for expiration dates, batch codes, and logos on plastic, glass, and metal package materials.

In conclusion, dot peen marking is best suited for applications requiring deep, durable marks on rugged surfaces, while laser marking excels in high-precision, high-speed applications, especially when working with delicate materials.

Dot Peen Marking vs. Laser Marking: How to Choose?

Selecting the right marking technology—dot peen or laser—depends on your specific application requirements, material type, budget, and production needs. Here’s a detailed guide to help you make an informed decision:

When to Choose Dot Peen Marking

Dot peen marking is ideal for applications that require durability, cost-effectiveness, and simplicity. If you need to label metals or hard polymers, particularly in harsh conditions, dot peen is a trustworthy solution. Its mechanical method produces deep, permanent indentations that can endure wear, corrosion, and exposure to hostile circumstances such as high temperatures or UV light. This makes it excellent for industries like automotive, aerospace, and heavy machinery, where parts are subjected to high stress.

Dot peen marking is also less expensive than laser systems in terms of initial investment. If you’re a tiny business or startup with limited resources, this technology provides a practical answer without sacrificing quality. Furthermore, dot peen markers can handle uneven or rough surfaces better than lasers, making them appropriate for situations where the surface finish is not absolutely smooth.

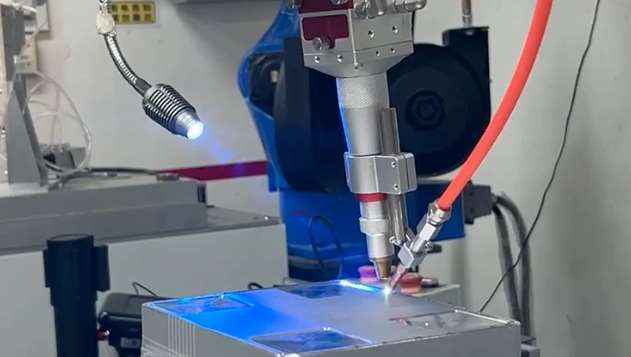

When to Choose Laser Marking

Laser marking, on the other hand, is the go-to solution for applications requiring precision, speed, and versatility. If your work involves delicate materials like glass, ceramics, or softer plastics, laser marking’s non-contact process ensures minimal risk of damage. It’s also perfect for creating high-resolution marks, such as barcodes, QR codes, or intricate logos, where fine details are critical.

Laser marking is faster for high-volume production, making it a better choice for industries like electronics, medical devices, and consumer goods, where speed and accuracy are paramount. While the initial investment is higher, the low maintenance and ability to mark a wide range of materials often justify the cost.

Key Considerations

When picking between dot peen and laser marking, consider various considerations.

First, evaluate the stuff you’re working with. Dot peen marking is great for metals and hard polymers, particularly in harsh conditions where longevity is required. Laser marking, on the other hand, is better suited for delicate materials such as glass, ceramics, and softer plastics because to its non-contact approach, which reduces the chance of damage.

Next, evaluate your budget. Dot peen marking systems are generally more affordable upfront, making them a practical choice for small businesses or applications with limited funding. Laser marking, while more expensive initially, offers long-term benefits like lower maintenance costs and greater versatility, which can justify the investment for high-precision needs.

Finally, consider your manufacturing environment and marking requirements. If you require deep, permanent marks that can resist severe environments, dot peen is the way to go. Laser marking is the best option for producing high-resolution, detailed marks in controlled situations. By balancing these considerations, you may choose the optimum technology for your application.

Summation

Both dot peen marking and laser marking offer unique benefits for industrial applications. Dot peen marking machines are robust, cost-effective, and ideal for creating deep, durable marks on metals and hard plastics, especially in harsh environments. Laser marking machines, on the other hand, provide unmatched precision, speed, and versatility, making them perfect for detailed marks on materials like glass, ceramics, and delicate plastics. When choosing, consider factors like material type, marking requirements, and budget. For durable, high-impact marks, go with dot peen marking. For intricate, high-speed marking, laser marking is the better choice.

If you are still not sure about your choice, you can consult a professional to find the best fit for your needs. Get start now!

Recommended Products