Electric vs. Pneumatic Dot Peen Marking Machine: Which is Better?

Dot peen marking machines have become an indispensable tool in industrial marking, providing permanent, high-quality marks on various materials. When marking serial numbers, barcodes, or logos on various substrates – using serial numbers as an example – selecting an electric or pneumatic dot peen marking machine is key to getting optimal results. In this blog, we’ll compare both electric and pneumatic dot peen marking machines by discussing differences between electric and pneumatic marking machines as well as the pros/cons for each to help make an informed choice if either choice might work better for your purposes based on personal marking requirements and personal choice!

What is Dot Peen Marking Machine?

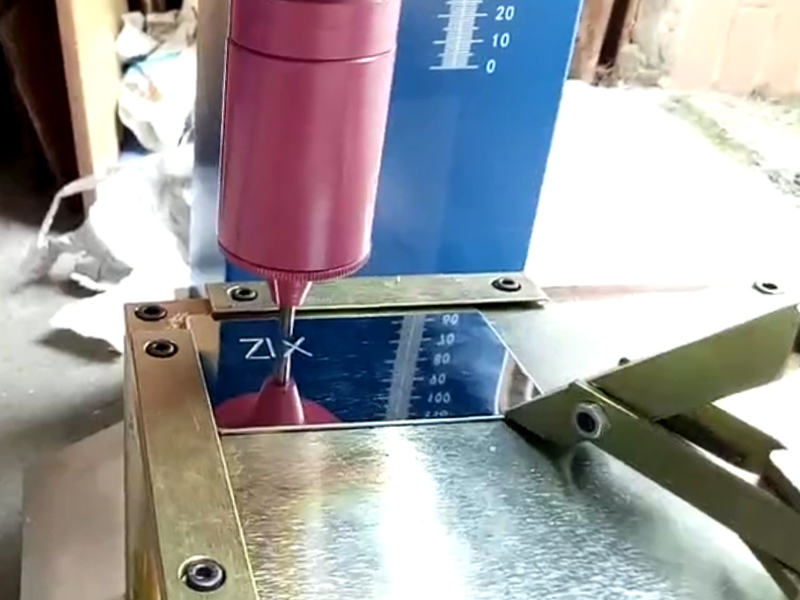

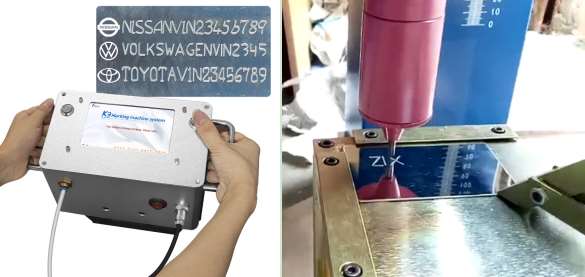

Dot peen markers are highly specialized tools used for producing permanent and high-precision marks on materials such as metal, plastic and composites. It uses a stylus to form small dots that form characters, numbers, logos or barcodes – widely utilized across industries including automotive, aerospace, manufacturing and electronics for use such as part identification, traceability and branding applications.

Dot peen marking works by moving a stylus in an automated pattern, producing consistent and accurate marks with depth, spacing, and speed that can be tailored specifically to suit different marking needs. Dot peen marks have become valued due to their durability – resisting wear, heat and corrosion.

Dot peen marking machines come in two main varieties: electric and pneumatic. Each type has unique strengths that make it well suited to various applications and environments, so understanding these options is key when selecting the ideal machine for you.

Electric vs. Pneumatic Dot Peen Marking Machine

Dot peen marking machines come in two main varieties: electric and pneumatic. Both serve the same fundamental function–creating permanent, high-precision marks on various materials–but their methods of operation, efficiency, and suitability for different applications can vary widely. We will explore how each type works as well as their best-use scenarios as well as potential advantages and limitations of each machine type.

Working Principles Outlined

- Electric Dot Peen Marking Machines

Electric dot peen marking machines use an electrically driven solenoid or motor to control a marking pin that moves up and down in response to electrical signals, striking surfaces in an intentional and consistent fashion to create closely spaced dots that form characters, numbers or logos. Both force and depth of marking are electronically managed for consistent and precise marking.

As electric dot peen machines don’t require air compressors, they tend to be smaller and more portable than their pneumatic counterparts. Their quiet operation also makes them ideal for environments with noise restrictions; additionally, these models often offer digital control features such as variable depth settings and custom software-based marking patterns.

- Pneumatic Dot Peen Marking Machines

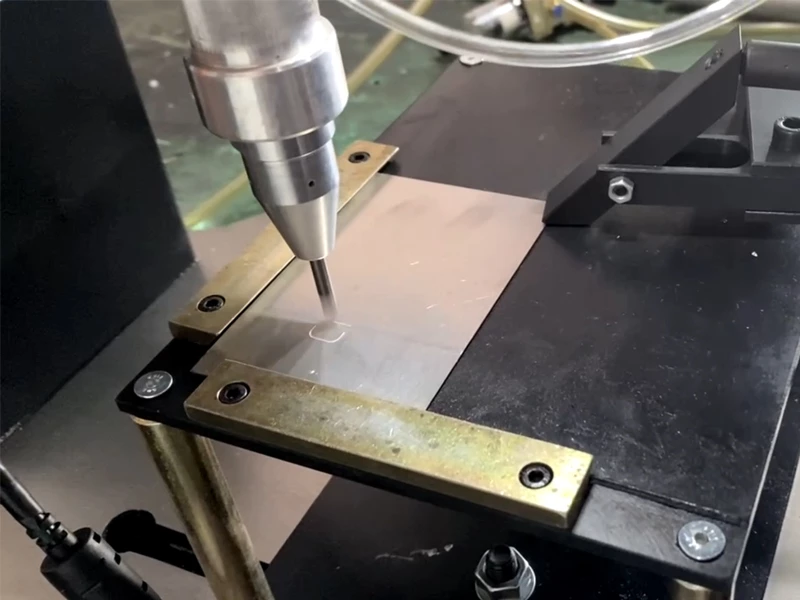

These pneumatic dot peen marking machines utilize compressed air pressure to drive their marking pin, propelling it at high speed against surfaces to mark designs faster and deeper than comparable electric machines.

Pneumatic machines are known for their high-speed performance and ability to efficiently engrave hard metals efficiently, though they require an external air source, necessitating additional equipment and maintenance expenses. Nonetheless, pneumatics machines remain widely utilized across industries that demand large-scale and fast marking processes such as automotive and heavy machinery manufacturing.

Applications

Different operational mechanisms determine which applications each machine is best suited for.

Electric Dot Peen Marking Machines: Electric dot peen machines are ideal for applications where precision and fine detail are key, such as electronics manufacturing, medical device production, and tooling industries. Due to their ability to engrave intricate designs without errors, electric machines also make for great low to medium-volume production environments due to their flexibility and accuracy.

Pneumatic Dot Peen Marking Machines: On the contrary, pneumatic models are tailored for high-volume production and heavy-duty applications, like automotive manufacturing, aerospace production, or heavy equipment assembly. Pneumatic machines excel in industries like automotive production, aerospace production, or heavy equipment assembly where parts needing marking may be larger, thicker, or made of harder materials than normal.

Furthermore, pneumatic marking machines can engrave serial numbers, part numbers, and other essential identifiers onto parts at an impressive pace – an advantage over pneumatics when using dot peen marking machines which mark deeper or faster compared with their counterparts – making pneumatics ideal for large-scale operations needing serial numbers or part numbers engraved at speed on large-scale operations needing serial numbers, etc engraving serial numbers or part numbers simultaneously on parts as required identification marks on parts.

Pros and Cons

Next, we need to know the pros and cons of electric dot peen machines and pneumatic marking machines.

| Feature | Electric Dot Peen Machine | Pneumatic Dot Peen Machine |

| Pros | ✅ High precision and consistency | ✅ Faster marking speed |

| ✅ Lower maintenance requirements | ✅ Better suited for heavy-duty applications | |

| ✅ Quieter operation | ✅ More cost-effective upfront | |

| ✅ Energy-efficient | ✅ Can engrave deeper on hard materials | |

| Cons | ❌ Slower marking speed | ❌ Noisy due to air compression |

| ❌ Higher initial cost | ❌ Requires regular maintenance (air compressor upkeep) | |

| ❌ Less effective for deep marking | ❌ Higher long-term energy consumption |

Choose Between Electric & Pneumatic Dot Peen Marking Machine

Consider these factors when making your selection between electric and pneumatic dot peen marking machines:

- Material Hardness: When dealing with harder materials, pneumatic machines may prove more suitable due to their powerful impact. However, advancements in electric machines have reduced this disparity significantly and now suit a wider array of materials.

- Installation and Maintenance: Electric machines tend to be simpler to set up and maintain, only needing standard power supplies; pneumatic ones, however, necessitate an air source, creating additional complexity as well as potential maintenance challenges.

- Cost Considerations: Electric machines typically have lower operational costs due to their lack of an air supply requirement, while pneumatic ones might incur extra expenses related to air compressors and their maintenance needs.

- Portability: For maximum portability, electric machines – specifically battery-powered models – provide greater versatility without needing an air compressor.

To Conclude

Both electric and pneumatic dot peen marking machines offer unique advantages depending on your industry’s specific requirements. Electric machines excel in terms of precision, noise reduction, and efficiency – ideal for smaller high-precision applications requiring greater precision. Pneumatic marking machines provide fast marking depth at lower costs with greater speed and robustness suited for large-scale operations requiring deeper marking depths. By taking into account all relevant factors above you can make an informed decision that maximizes productivity and ensures superior marking quality.

Recommended Products