Energy & Chemical

Both the energy and industrial sectors use all kinds of metal parts in critical areas, from structural components to pipes and connectors, from small tools to nameplates on large machines, there are a large number of parts that need to be marked with date of manufacture, date of installation or serial number for quality traceability and maintenance purposes. In addition to pneumatic and laser marking, we also offer trendy laser welding and cleaning solutions to provide our customers with a one-stop solution.

Technologies For Energy & Chemical

The energy and chemical industries use a variety of standardized and non-standardized metal parts that require Direct Part Marking (DPM), and the identification and traceability of these critical metal parts is critical to the quality and longevity of the work. We entered this field with the pneumatic marking of industrial cylinders and flanges and through years of development are now able to offer a wide range of marking solutions from mobile to fully automated marking.

- Fast: to mark with same specific depth such as 0.3mm, our peen marking machine is 8~10X faster than a 100W fiber laser system;

- Depth: our peen marking machine offer 0.1~0.3mm depth in one pass, and able to precise repeat for deeper marks;

- Traceability: in addition to serial numbers or date marks, our peen markers can mark scannable DPM or QR codes for digital management.

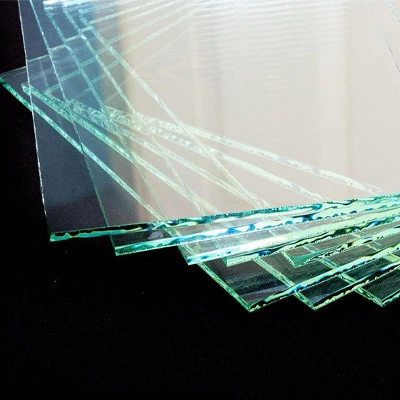

In fact, the dominant technology for direct part marking (DPM) is the use of lasers, especially for smaller metal parts and other non-metallic materials such as screws, PVC pipe, wire, glass, and so on. In addition, laser marking can be used to create easy-to-read warning labels. In addition to desktop and stand-alone machines, we also have a wide range of portable laser marking machines that allow our customers to work anywhere, anytime.

- Quiet: laser marking of metal also generates noise, especially deep engraving, but this is negligible compared to the peen marking process;

- Accuracy: Laser marking can mark metal in extremely small sizes, such as 3.7*3.7mm Data Matrix code or 0.03mm line width characters, which are impossible for peen marking;

- Visibility: Using MOPA fiber or UV laser for laser annealing instead of engraving for black or other color marking on metal workpieces with high contrast.

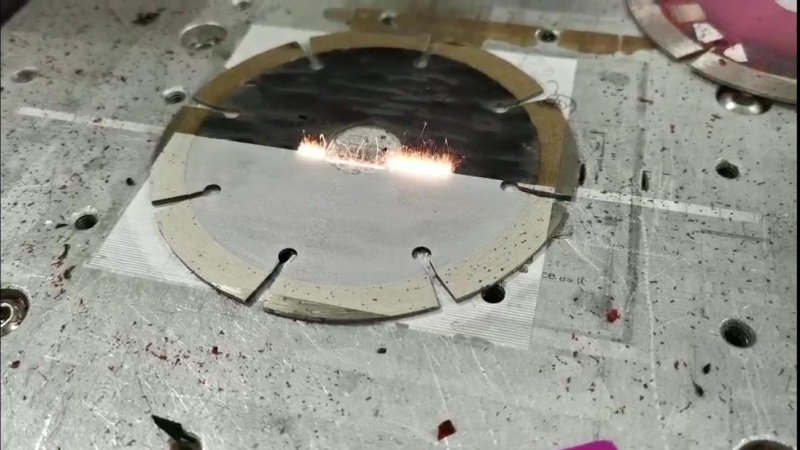

Laser welding is widely used for high-pressure pipelines and storage tanks in the energy and chemical industries. The use of automated laser platform welders provides extremely homogeneous weld quality and a simpler structure than MAG, making it more suitable for integrated automation. In addition, precision laser welding, including galvo welding, is also used in the manufacture of lithium-ion batteries and the repair of precision instruments.

- Easy to use: extremely consistent weld quality that requires less operator skill than TIG and MIG welding;

- Precise: QCW or MOPA fiber laser welding system produces extremely small spots and weld marks for high-precision welding of thin sheets, films, electronic circuits and more;

- Easy to automate: the physical structure of laser welding is simpler than that of TIG, MIG or MAG, which facilitates the development and use of automated welding.

Laser cleaning technology without detergents or intermediate catalysts is now widely used in industry for cleaning, coating and corrosion control, maintenance and restoration of all types of equipment. Compared to traditional cleaning methods, laser cleaning can be 2 to 10 times faster, and it is easier to automate the cleaning process to achieve less damage and better cleaning efficiency.

- Efficiency: the high-energy laser beam vaporizes contaminants in a very short time with minimal damage to the workpiece.

- Non-consumable: laser cleaning can be operated without detergents or catalysts, a significant savings for high-volume industrial metal derusting.

- Non-contact: laser beam can remove rust, oxides, oil, grease, paint and coating at a distance, therefore suitable to clean hard-to-touch workpiece such as injection mold.

Explore Our Machines For Energy and Chemical

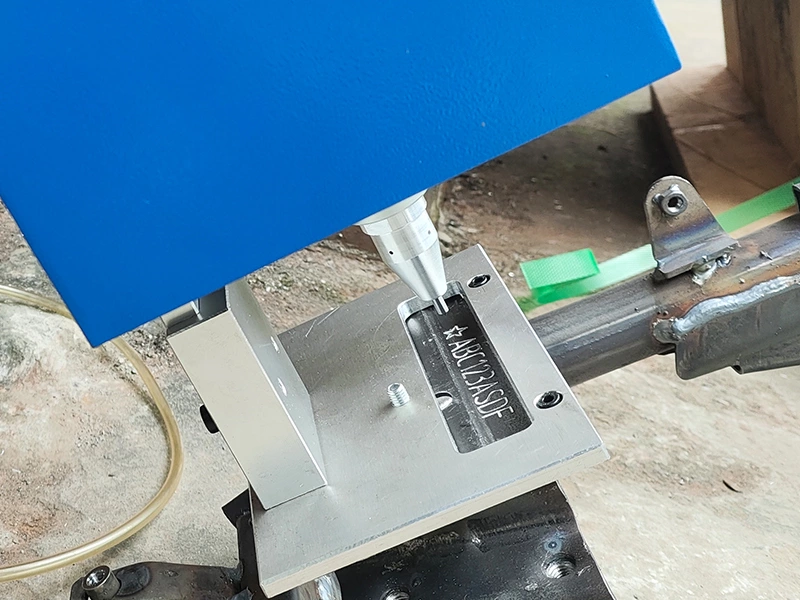

Typically, all industrial gas cylinders and other storage devices need to be cleaned and marked with an expiration or filling date. We have developed and patented a variety of fixtures for hand-held peen marking machines for various diameters and shapes of cylinders, and this series is one of our best selling products. We also offer automated rotary peen or laser marking systems for larger storage containers.

Flange manufacturers are challenged with a wide range of diameters and weights for their marking needs. We have standardized and customizable lines of peen marking machines for common weights and diameters. In addition, some flange manufacturers need to mark their flanges with finer and high contrast logos or SN numbers, we also offer laser marking solutions from portable handheld markers to multi-axis systems.

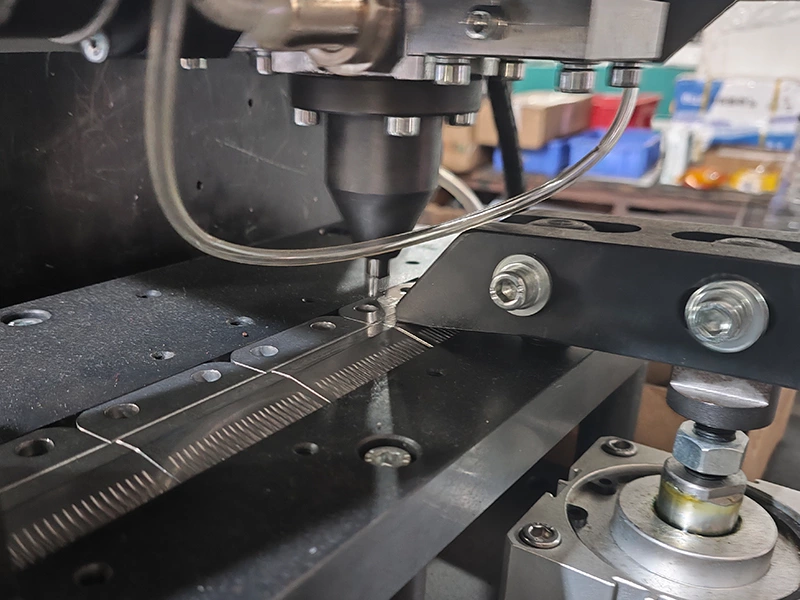

When it comes to tube welding, laser welding technology offers many advantages over traditional arc welding, including lower weld stress, less weld distortion and higher weld speeds. For common carbon or stainless steel pipe welding needs, we offer standard, reliable handheld laser welders as well as more customized solutions to further improve efficiency or quality. QCW and MOPA laser welders are also available to suit your pipeline material or special welding requirements.

Lithium batteries have evolved rapidly in recent years to meet the growing demand for energy storage for solar, wind and ocean power generation, as well as peak demand management. We offer a range of battery laser welding machines from laser spot welding to galvanometer scan welding systems, from manual to fully automated, to meet your battery manufacturing or remanufacturing needs.

Whether it’s removing carbon, oil, dust and other deposits from power generation and oil drilling equipment; removing rust, corrosion and old coatings from metal surfaces and large tank interiors; or cleaning wind turbine blades and nacelles, we offer reliable and efficient continuous wave (CW) and pulsed fiber optic cleaners to meet your cleaning needs.

Want an un art handing video demonstration on specialized material? Looking for a solution to your specialized environment or automatic process demand?