MOPA Fiber Laser Marking Machine

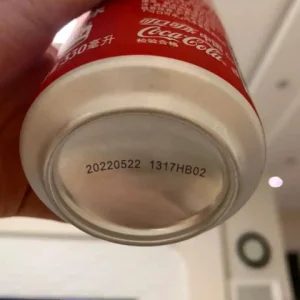

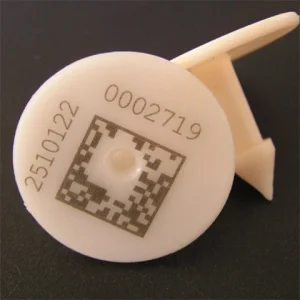

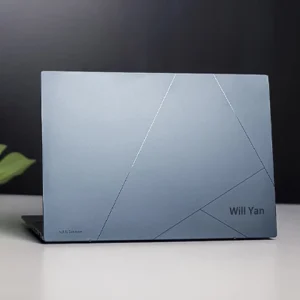

Since 2011, we have evolved from dot peen markers to laser markers, capable of producing complex, high-contrast, durable marks on a wide range of materials and products with minimal damage to surrounding materials. In addition, we can also mark logos, production information, packaging labels, unique device identifiers (UDI), barcodes, data matrix (QR codes), production dates, expiration dates and other graphic content.

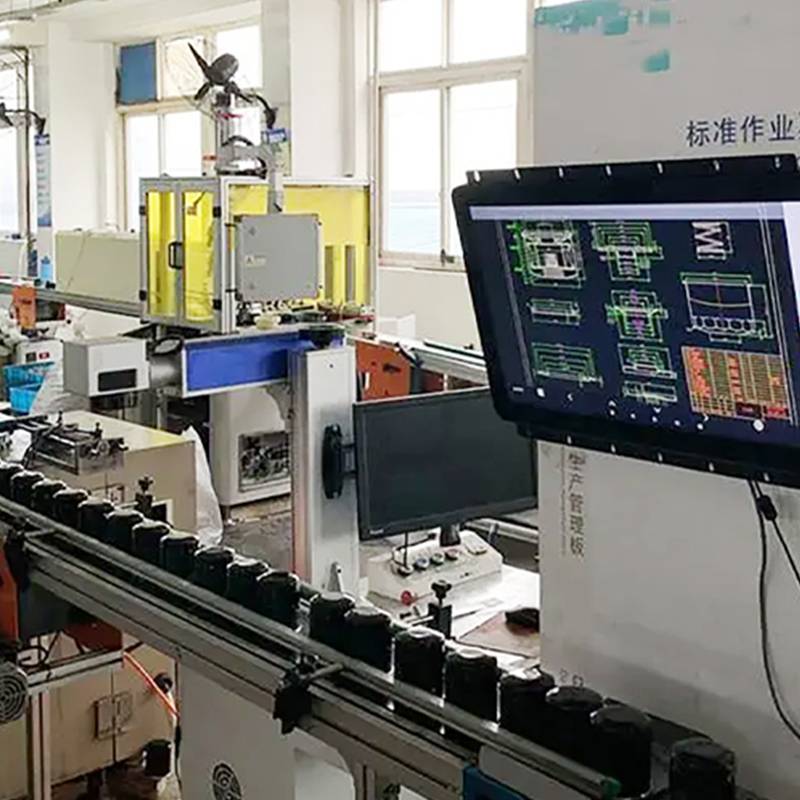

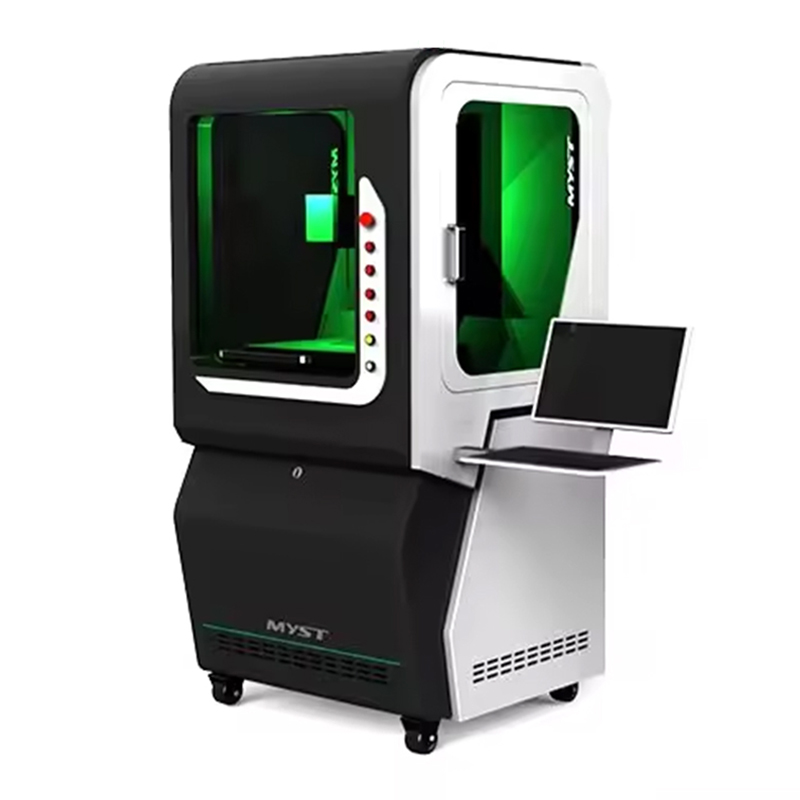

In addition to fiber, fiber MOPA, UV, and CO2 laser marking machines, we offer machine formats such as tabletop, stand-alone, enclosed, flying, and portable machines, as well as large format, autofocus, 3D scanners, vision positioning, multi-axis control systems, and other upgrades to meet the needs of a wide variety of customers marking a wide range of differently shaped material workpieces.

For product pricing, customization, or other inquiries:

Description

Fiber laser has become the most widely used type in the industrial laser field in recent years due to its durability advantages and price advantages. Generally speaking, fiber laser marking machine also includes sub-categories such as MOPA fiber laser marking machine, nanosecond, picosecond and femtosecond ultrafast infrared fiber laser marking machines. We offer 20W, 30W and 50W power options for basic fiber laser marking machines and 20W, 30W, 50W, 60W, 100W, 200W, 300W, 500W MOPA fiber laser marking machines, and nimble machine type options including desktop, stand, flying on line and handheld models for all machines, which are inexpensive and reliable enough to perform the task of marking metals and hard plastics that do not require a high degree of appearance or depth of marking. You can also ask to customize an automated fiber laser system with advanced modules for further efficiency at a reasonable cost.

Whether you need to mark instruments such as scalpels that are resistant to abrasion or corrosion, or metal surfaces such as stainless steel or anodized aluminum alloys, using MOPA or ultra-fast fiber laser markers to mark black logos, model numbers and other manufacturer information, as well as QR codes, barcodes and UDIs for traceability, has become a common, efficient and cost-effective way to mark your products. These markings are permanent and aesthetically pleasing, and while not as efficient as traditional printing methods such as UV-cured inkjet printing, they reduce the cost and environmental impact of ink consumption in high-volume production, resulting in more sustainable production.

Technical data of our standardized fiber laser marking & engraving machines

Choose from our standard machines below and slide to the right for more information, or contact us for a solution.

| Typical Appearance | Machine Type | Laser Source Brand | Laser Wavelength | Laser Power | Optional Upgrades | Work Area | Software | Mark Speed | Positioning Speed | Writing Speed | Precision and Error | Duration | Operation Environment |

| Desktop Split | Fiber: IPG, Raycus or MAX Fiber MOPA: JPT or ask an advice | 1064nm | 20W, 30W, 50W, 60W, 100W, 200W, 300W, 500W | Electric lifting & lowering, 2.5D continous rotary marking, auto focus, 3D galvo (dynamic focusing), conveyor, etc. | 100*100mm ~ 300*300m, or customize | Pre-installed Ezcad 2 for standard machines, or ask for Ezcad 3, Lightburn, LaserRGBL, BSL, Keyence Marking Builder, Feeltek LenMark 3D, Syntek Laser Marking Controller, etc. | Standard: 5000mm/s (Sino-Galvo 7110) Faster: 8000mm/s (Sino-Galvo 7210) Fastest: 12000mm/s (Sino-Galvo 7210-A) | Standard: 8000mm/s (Sino-Galvo 7110) Faster: 15000mm/s (Sino-Galvo 7210) Fastest: 23000mm/s (Sino-Galvo 7210-A) | Standard: 450cps (Sino-Galvo 7110) Faster: 556cps (Sino-Galvo 7210) Fastest: 600cps (Sino-Galvo 7210-A) | Tracking Error Time: ≤164us (Sino-Galvo 7110) ≤144us (Sino-Galvo 7110) ≤138us (Sino-Galvo 7110) Linearity: 0.999 Repeatability (RMS): <8μRad Gain Error: <5mRad Zero Offset: <5mRad Long-term Drift Over 8 Hours: <0.5mRad Scale Drift: <40PPM/℃ Zero Drift: <15μRad/℃ | ≥100,000 working hours for 10% power attenuation | Power input: 100~240V, 50Hz or 60Hz Operation temperature: 0~40℃ or 32~104℉ Relative Humidity: 0~80% uncondensed |

| Desktop | Fiber: IPG, Raycus or MAX Fiber MOPA: JPT or ask an advice | 1064nm | 20W, 30W, 50W, 60W, 100W, 200W, 300W, 500W | ≥100,000 working hours for 10% power attenuation | ||||||||

| Stand-alone | Fiber: IPG, Raycus or MAX Fiber MOPA: JPT or ask an advice | 1064nm | 20W, 30W, 50W, 60W, 100W, 200W, 300W, 500W | ≥100,000 working hours for 10% power attenuation | ||||||||

| Flying | Fiber: IPG, Raycus or MAX Fiber MOPA: JPT or ask an advice | 1064nm | 20W, 30W, 50W, 60W, 100W, 200W, 300W, 500W | ≥100,000 working hours for 10% power attenuation | ||||||||

| Enclosed | Fiber: IPG, Raycus or MAX Fiber MOPA: JPT or ask an advice | 1064nm | 20W, 30W, 50W, 60W, 100W, 200W, 300W, 500W | Electric lifting & lowering, automated door, 2.5D continous rotary marking, auto focus, 3D galvo (dynamic focusing), conveyor, air exhaust, etc. | ≥100,000 working hours for 10% power attenuation | |||||||

| Gantry | Fiber: IPG, Raycus or MAX Fiber MOPA: JPT or ask an advice | 1064nm | 20W, 30W, 50W, 60W, 100W, 200W, 300W, 500W | 2D moving plateform, 2.5D continous rotary marking, 3D galvo (dynamic focusing), etc. | 600*600mm ~ 1500*1200m, or customize. | ≥100,000 working hours for 10% power attenuation | ||||||

| Cart | Fiber MOPA: JPT or ask an advice | 1064nm | 60W, 100W, 200W, 300W, 500W | Customized fixtures for VIN, engine, pipe, cable or cylinder. | 200*80mm or customize. | Ezcad 2 | ≥100,000 working hours for 10% power attenuation | |||||

| Handheld | Fiber: MAX | 1064nm | 20W, 30W, 50W | Integrated Li-on battery inside. | 100*100mm | Sunine | Standard: 5000mm/s | Standard: 5000mm/s | Standard: 450cps | ≥100,000 working hours for 10% power attenuation |

Material compatibility of our laser type

Review the material you want to mark or engrave. Check out our material application pages for real-world cases.

| Material to mark or engrave | Fiber | MOPA | UV | CO2 |

| Metals | √ | √ | ○ | – |

| Precious Metals | ○ | √ | ○ | – |

| Plastic | ○ | √ | √ | √ |

| Glass | – | ○ | √ | ○ |

| Ceramics | – | – | √ | √ |

| Acrylics | – | ○ | √ | √ |

| Leather | – | – | √ | √ |

| Wood | – | – | √ | √ |

| Stone | – | – | ○ | √ |

| Textile | – | – | √ | √ |

| Paper | – | – | √ | √ |

| Carbon Fiber | – | – | √ | – |

Tips:

√ means the laser type is ideal for marking or engraving these materials;

○ means the laser type will work to mark or engrave these materials, but the requirements are more demanding;

– means the laser type is not recommended for the job.

Marking Samples

Clients who chose our fiber laser marking and engraving machines.

FAQs about our laser marking machines.

Want an un art handing video demonstration on specialized material? Looking for solution of your specialized environment or automatic process demanding?