Fiber Laser vs. Dot Peen: Which Metal Marking Machine is Right for You?

Metal marking is an essential process for a wide range of industries. Whether it’s to ensure traceability, comply with regulations, or enhance product branding, selecting the right metal marking machine is key to achieving high-quality, efficient results. In this article, we will compare two popular metal marking technologies—Fiber Laser and Dot Peen—and help you determine which is best suited for your needs.

What Industry Need Metal Marking?

Metal marking, often in the form of metal tags or metal labels, is widely used across various industries due to its durability, versatility, and ability to convey important information. Here are some industries that commonly need metal marking:

- Industrial Manufacturing: Metal marking is extensively used in industrial manufacturing to label products, manage inventory, and prevent misplacement or loss of goods. It is often found on machinery, equipment, and electrical accessories that require frequent replacement or maintenance, facilitating easy management and tracking.

- Transportation and Infrastructure: Metal signs and markings are used in transportation facilities such as highways, where they serve as indicators or directional signs. Vehicle license plates often contain metal markings for identification purposes.

- Safety and Security: In environments requiring special safety measures, such as laboratories and hospital operating rooms, metal markings (like stainless steel nameplates) enhance safety by providing clear identification and instructions.

- Architectural and Decorative Uses: Metal markings are also used in the architectural and decorative fields, where they serve as aesthetic elements or for branding purposes. They can be found on building exteriors, interior decorations, and even in home furnishings.

- Retail and Commercial Spaces: In retail and commercial settings, metal markings are used for branding, product identification, and promotional purposes. They can be seen on product packaging, store signage, and promotional materials.

- Public Spaces and Educational Institutions: Metal markings play a crucial role in public spaces like community squares and parks, providing navigational and informational signage. In educational institutions, they help create an organized and informative campus environment by guiding students and visitors.

In summary, metal marking is essential in a wide range of industries due to its durability, ability to withstand harsh environments and clear communication of important information.

Types of Metal Marking Machine

Metal marking machines come in various types, each tailored to meet specific marking needs and material types. The two most widely used technologies in the industry are Fiber Laser Marking and Dot Peen Marking. Here’s a closer look at how each method works and what they offer.

Fiber Laser Marking Machine

Fiber laser marking technology uses a concentrated laser beam to etch or engrave metal surfaces with exceptional precision, resulting in high-contrast, permanent markings. Known for its speed and accuracy, fiber laser marking is favored for high-precision applications where detailed designs and readability are crucial.

- Precision and Detail: Produces sharp, crisp marks, ideal for small text, logos, barcodes, and intricate patterns.

- High Speed: Laser marking operates quickly, making it suitable for high-volume production environments that prioritize efficiency.

- Low Maintenance: Fiber lasers are durable and typically require minimal maintenance, providing a cost-effective, long-lasting solution.

- Material Versatility: Compatible with a wide range of metals, including stainless steel, aluminum, and precious metals.

- Non-Contact Process: The laser marking process does not involve direct contact with the material, reducing wear on both the equipment and the material itself.

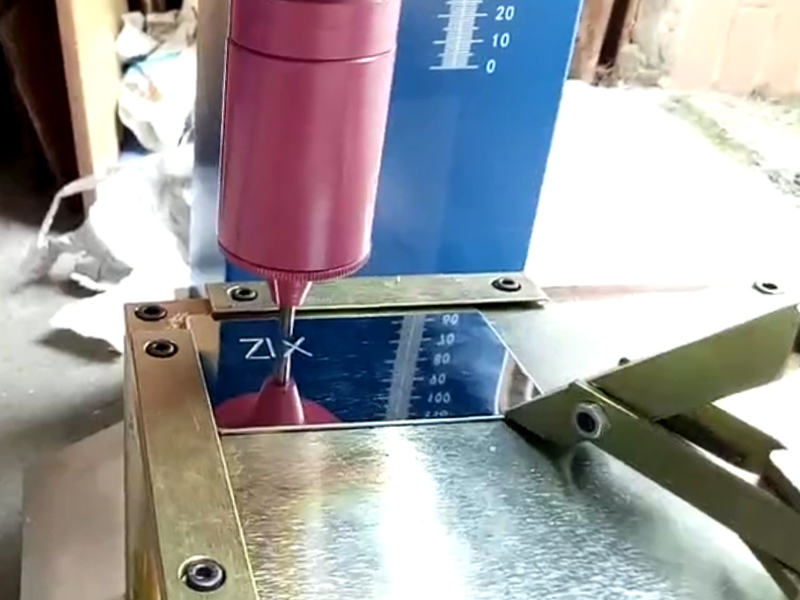

Dot Peen Marking Machine

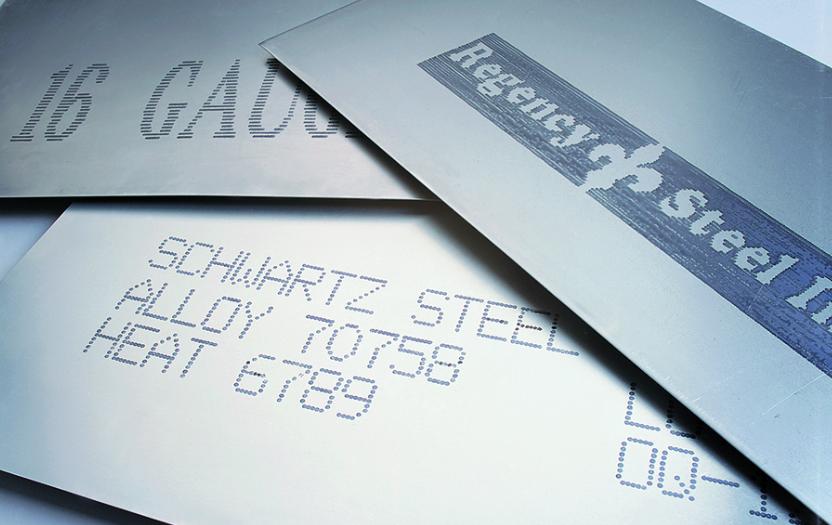

Dot peen marking uses a pneumatically or electrically powered stylus to produce a series of small, closely spaced dots, which together form letters, numbers, or designs. This method physically indents the metal, creating robust, permanent marks that are ideal for applications requiring deep impressions, even on tougher or uneven surfaces.

- Durable, Deep Marks: Produces deep, long-lasting marks that remain clear and readable in harsh conditions, even with wear or exposure to the elements.

- Material Flexibility: Effective on a wide variety of metals, including hard, rough, or curved surfaces, offering versatility in different applications.

- Cost-Effective: Typically more affordable than fiber lasers, making it a practical choice for small and medium-sized businesses with budget considerations.

- Ideal for Heavy-Duty Applications: Particularly well-suited for marking large or heavy components, making it a preferred option in industries such as automotive, aerospace, and manufacturing.

- Adaptable for Rough Surfaces: Unlike laser marking, dot peen technology excels on rough, unfinished, or irregular surfaces, making it a reliable option for non-smooth materials.

Both Fiber Laser and Dot Peen marking technologies are effective for creating durable, high-quality marks on metal. However, choosing between them depends on the specific needs of your application—fiber lasers for fine, high-speed marking and dot peen for deep, rugged engraving.

Fiber Laser vs. Dot Peen Marking

When choosing a metal marking machine, it’s essential to understand the differences between Fiber Laser and Dot Peen technologies. Each offers unique strengths and is suited to different applications, depending on factors like marking precision, speed, cost, and durability. Here, we’ll break down the core differences between these two methods and provide a comparison table for easy reference.

- Fiber Laser Marking uses a high-powered laser to etch or engrave the metal surface. It’s known for producing sharp, high-contrast, and detailed marks with precision and speed. This technology is ideal for industries that require clear and intricate markings, such as electronics, medical devices, and luxury goods.

- Dot Peen Marking, on the other hand, employs a pneumatically or electrically controlled stylus that strikes the metal surface to create a series of small dots. These dots form characters, symbols, or designs that are permanent and highly durable. Dot peen is typically used in heavy-duty industries like automotive and aerospace, where deep, long-lasting marks are essential for part traceability and identification.

| Feature | Fiber Laser Marking | Dot Peen Marking |

| Precision | High precision, ideal for intricate designs and fine details | Lower precision, better for larger text and simpler designs |

| Speed | Faster, ideal for high-volume production | Slower, better for deep marking on large items |

| Material Compatibility | Best for softer metals like aluminum, steel, brass, and titanium | Works well on both soft and hard metals, including rough surfaces |

| Durability | Long-lasting with minimal maintenance | Requires more maintenance due to wear on stylus |

| Cost | Higher initial cost but low maintenance over time | More affordable upfront, but higher maintenance costs |

| Best for | Fine text, serial numbers, barcodes, logos, small items | Deep, durable marks on large, rough, or hardened materials |

| Common Industries | Aerospace, automotive, medical devices, electronics | Automotive, industrial equipment, construction, metalworking |

In a word, choosing between Fiber Laser Marking and Dot Peen Marking ultimately depends on your specific needs. If you require precision, speed, and fine details for high-volume production, Fiber Laser Marking is likely the better choice. If you’re working with tough, rough materials and need deep, durable marks, Dot Peen Marking might be more suitable.

Want to Find Metal Marking Solutions?

Choosing the right metal marking solution is crucial for achieving the best results in your production process. Whether you need precision, speed, or durability, selecting the right machine depends on your specific needs—whether it’s for high-speed marking on small parts or deep engravings on larger, tougher materials.

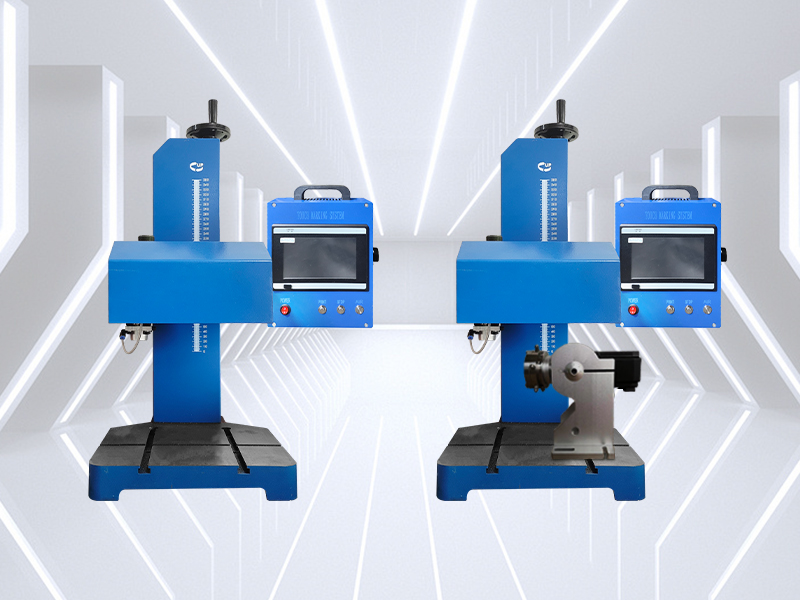

If you’re looking for a reliable and trusted partner for your metal marking needs, Zixu Machine offers high-quality, cutting-edge solutions designed to meet the demands of various industries.

Ready to find the perfect metal marking solution? Visit Zixu Machine today and explore their range of advanced marking machines and equipment, backed by professional support and service to ensure you get the best out of your investment.

Recommended Products