Flexible Automatic Rotary Dot Peen Marking Machine for Steel Bars, Rods and Pipes

This is a customized steel bar marking station for marking the circumference of steel bars weighing less than 300 kg and ranging in length from 300 mm to 2500 mm, where the marking position must be flexibly adjustable from 100 mm to 500 mm. In addition, due to the weight and size, the customer needed to use equipment such as an overhead crane to load and control the entire marking station at a lower cost.

Due to the high cost of the clamping and rotary marking solution on a full line conveyor, the customer selected the 1800mm roller rotary marking workstation after a site survey and communication with the customer’s process engineers.

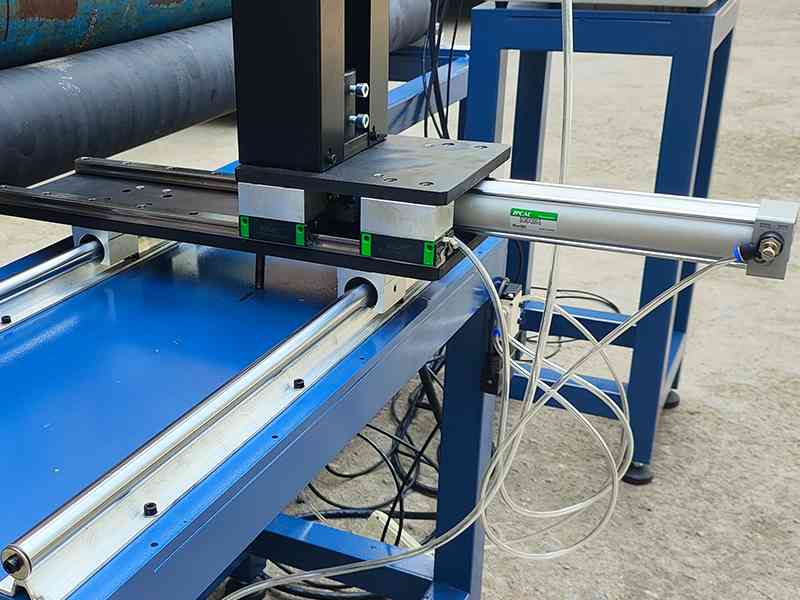

The system is equipped with a movable working platform to carry the marking machine, in which the X-direction uses a manual sliding guide with 500mm stroke and a manual locking device, and the Y-direction uses a cylinder-driven moving module, so that after manually adjusting the position of the marking machine through the PLC control to realize the marking machine ejection and retraction, to allow the customer to carry out the lowering and loading of the material.

If you are looking for automatic dot peen marking solution, in reliable quality and reasonable cost, contact us.