Gas Cylinder Marking Machines: Why It Matters

Gas cylinders, as essential components of various industries, require precise and permanent identification for safety and regulatory compliance. This is where gas cylinder marking machines play a crucial role. These specialized devices are designed to engrave or imprint information onto gas cylinders, ensuring their traceability and preventing accidents. Whether there are co2 cylinder engravers, o2 cylinder engravers, or h2 cylinder engravers in your hands now, by understanding the importance of gas cylinder marking and the benefits offered by marking machines, you can make informed decisions to enhance safety, efficiency, and compliance within their operations.

Why Choose Gas Cylinder Marking Machines to Marking?

Precision and Speed

Gas cylinder marking machines offer unparalleled precision and speed in the marking process. With just a few clicks, you can input any character, eliminating the need for manual adjustments. This automation not only saves time but also ensures consistent and accurate markings on every cylinder.

High Visibility and Traceability

By engraving markings directly onto the cylinder’s surface, these machines create permanent, highly visible marks. This level of visibility is crucial for easy identification and tracking of cylinders throughout their lifecycle. Additionally, the permanent nature of these markings ensures that the cylinder’s history and associated data remain intact, even in harsh environments.

Low Lifecycle Cost

Gas cylinder marking machines, particularly pneumatic models, are designed for efficiency and cost-effectiveness. They typically consume only compressed air and needles, resulting in minimal operating costs. Furthermore, these machines are built to last, with few moving parts and a robust design that minimizes downtime and maintenance requirements.

Increased Efficiency

Gas cylinder marking machines are designed to streamline the marking process, improving overall efficiency and productivity. The automation features of these machines eliminate the need for manual adjustments and reduce the time required to mark each cylinder. Moreover, the customization options available allow businesses to tailor the marking process to their specific needs, further enhancing efficiency. By investing in a reliable gas cylinder marking machine, businesses can reduce labor costs, improve turnaround times, and increase overall productivity.

Customization Options

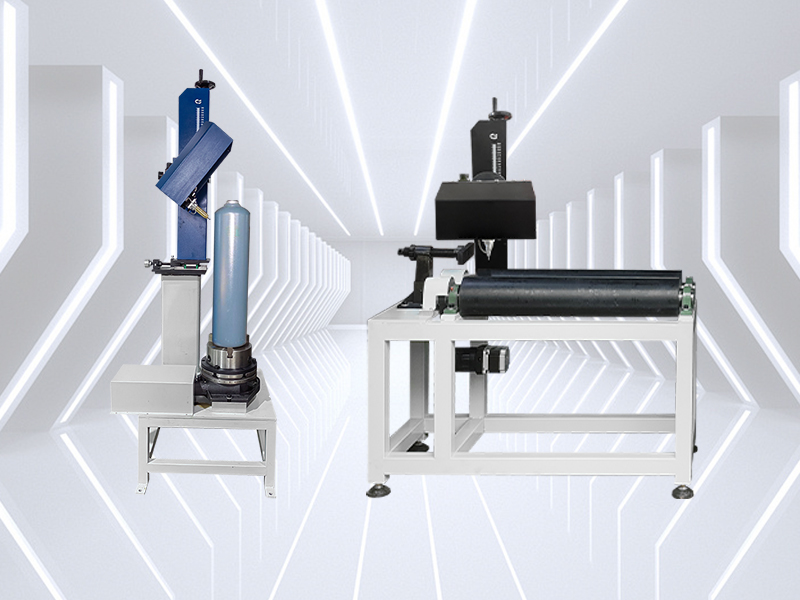

For businesses with unique marking needs, gas cylinder marking machines offer a high degree of customization. Companies like Zixu provide a range of solutions, including both horizontal and vertical systems, to accommodate cylinders of various sizes and weights. This flexibility allows you to tailor the marking process to your specific requirements, ensuring optimal efficiency and productivity.

What Types of Information Are Typically Marked by Gas Cylinder Marking Machines on Gas Cylinders?

Here are some of the most common types of information marked by gas cylinder marking machines:

| Identification Information | Serial number | Each cylinder is assigned a unique serial number for easy identification and tracking. |

| Date of manufacture | The date when the cylinder was produced is engraved to help determine its age and remaining lifespan. | |

| Cylinder type | The specific type of gas the cylinder is designed to hold, such as oxygen, nitrogen, carbon dioxide, or propane. So you may need a co2 cylinder engraver, o2 cylinder engraver, or h2 cylinder engraver. | |

| Safety Information | Pressure rating | The maximum pressure the cylinder can safely withstand. |

| Weight | The total weight of the cylinder, including the empty weight and the weight of the gas. | |

| Manufacturer’s name and logo | The identity of the company that produced the cylinder. | |

| Warning symbols | Visual cues, such as a flame symbol for flammable gases or a skull and crossbones for toxic gases, to alert users to potential hazards. | |

| Regulatory Compliance Information | Country of origin | The country where the cylinder was manufactured. |

| Certification marks | Symbols or codes indicating that the cylinder meets specific safety and quality standards. | |

| Expiry date | The date after which the cylinder is no longer considered safe for use. | |

| Additional Information | Department of Transportation (DOT) markings | For cylinders used in the United States, specific DOT markings are required to comply with transportation regulations. |

| Hazard class | A number indicating the type of hazard associated with the gas, such as flammable, toxic, or corrosive. | |

| UN number | A four-digit number assigned by the United Nations to identify hazardous substances. |

How Do I Ensure the Markings by the Gas Cylinder Marking Machine are Legible and Durable?

Machine Selection and Maintenance

- Choose a high-quality machine: Opt for a gas cylinder marking machine that is designed for durability and precision. Reputable manufacturers typically offer machines with robust construction and reliable components.

- Regular maintenance: Follow the manufacturer’s recommended maintenance schedule to keep your machine in optimal condition. This includes cleaning, lubrication, and calibration as needed.

Marking Materials and Techniques

- Use appropriate materials: Select marking materials that are specifically designed for gas cylinders and can withstand harsh environmental conditions. These materials should be resistant to fading, corrosion, and abrasion.

- Proper marking techniques: Follow the manufacturer’s instructions for marking the cylinders. Ensure that the markings are deep enough to be legible over time and that the machine is properly adjusted to avoid smudging or unevenness.

Environmental Factors

- Storage conditions: Store cylinders in a controlled environment to protect the markings from exposure to extreme temperatures, humidity, and contaminants.

- Handling and transportation: Handle cylinders carefully to avoid damaging the markings during transportation and storage.

Inspection and Verification

- Regular inspections: Periodically inspect the cylinders to ensure that the markings are still legible and intact.

- Verification procedures: Implement verification procedures to confirm that the markings are accurate and comply with relevant regulations.

Gas Cylinder Marking is Essential

Gas cylinder marking machines are essential tools for businesses in industries that use gas cylinders. These machines help to ensure safety, traceability, and regulatory compliance by producing precise, permanent, and easily readable markings. The advantages of using gas cylinder marking machines include increased efficiency, lower risk, and better inventory management. Businesses that invest in a reliable marking machine can ensure the safe and responsible handling of gas cylinders, protecting both their employees and the environment.

Recommended Products

.jpg)