Laser Etching and Engraving on Glass & Crystal

Glass Laser Process, From One-offs to Mass Production.

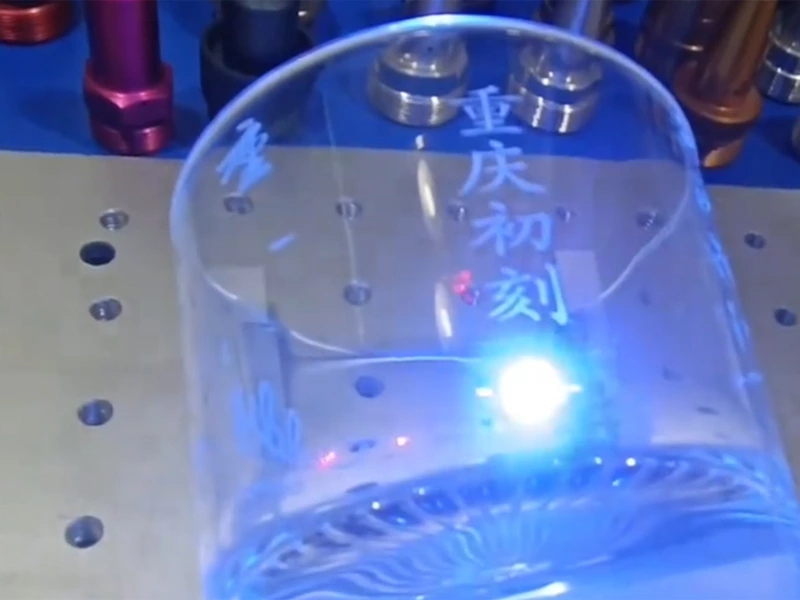

Glass laser engraving and some people called glass laser etching is a gaining popularity method for glass frosting or furring, it consumes nothing but electricity only compared to glass acid etching, sandblasting or etching cream, and easy to adjust etching area, shape and location with real-time indicator. In addition, you can adjust the laser power and pass times to adjust the marking depth on glass, but you do not need a cooling medium for the glass workpiece.

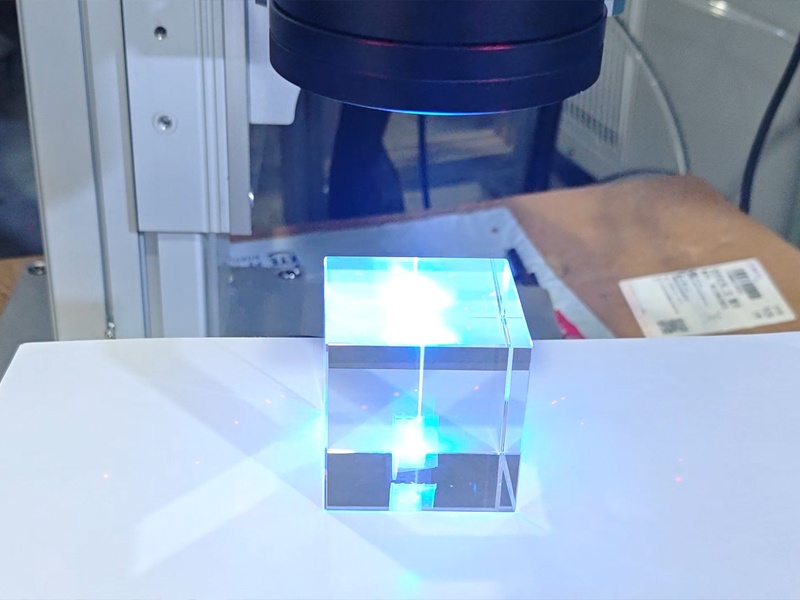

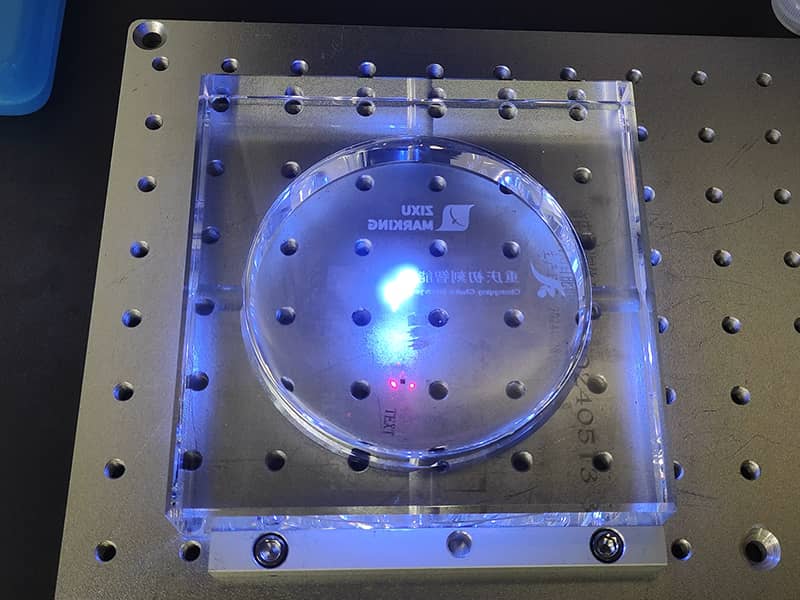

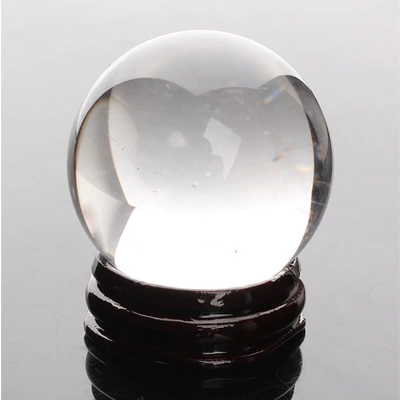

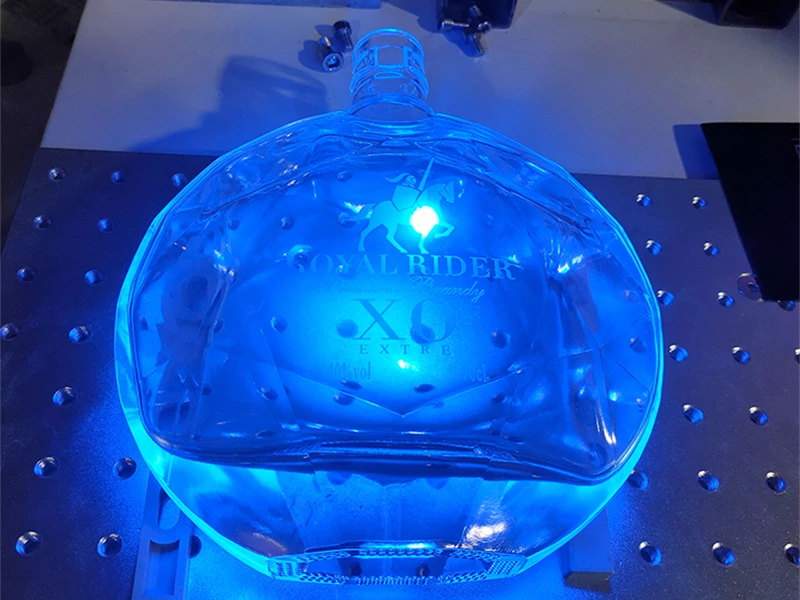

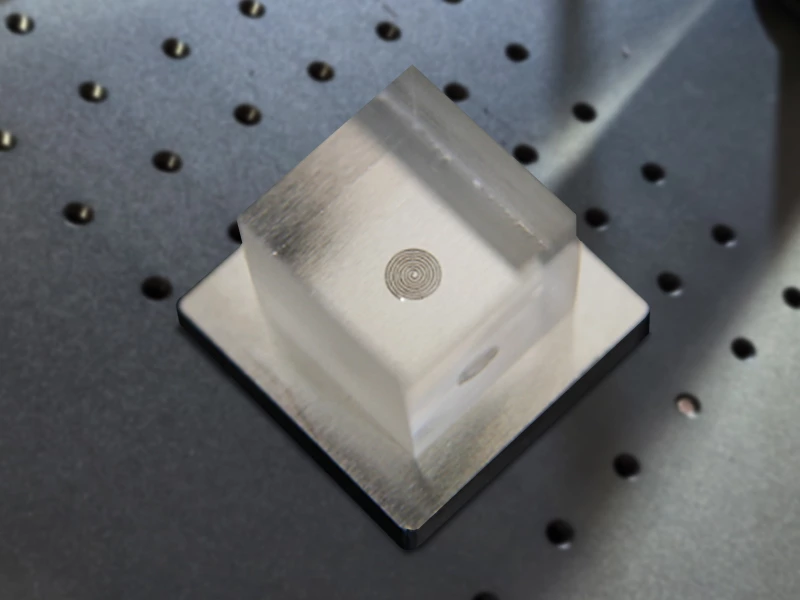

Glass & Crystal Laser Samples

Explore Our Glass Laser Processing Machines

What Should You Know About Glass Etching or Engraving?

Our customers produce a wide variety of glass products, so we don’t recommend standard UV, CO2 or MOPA fiber laser machines for everything. Rather, we prefer to offer you the best solution based on the sample you provide, the glass composition, the work environment, the production speed, and the target quality and budget.

There is a wide variety of glass products, so in addition to 2D, 3D and autofocus galvanometer solutions, Zixu also offer moving large format, continuous rotary marking, multi-axis marking and other functional modules to provide customers with the best solution to achieve the perfect balance of product quality, process speed and deployment cost.

If your glass products are doing well in the marketplace and you need to expand your production, we can also provide cost-effective, customized automation solutions and reliable technical support to help you maximize the value of your business with minimal investment of capital, time and manpower.

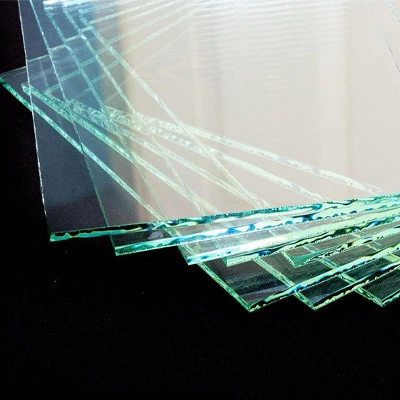

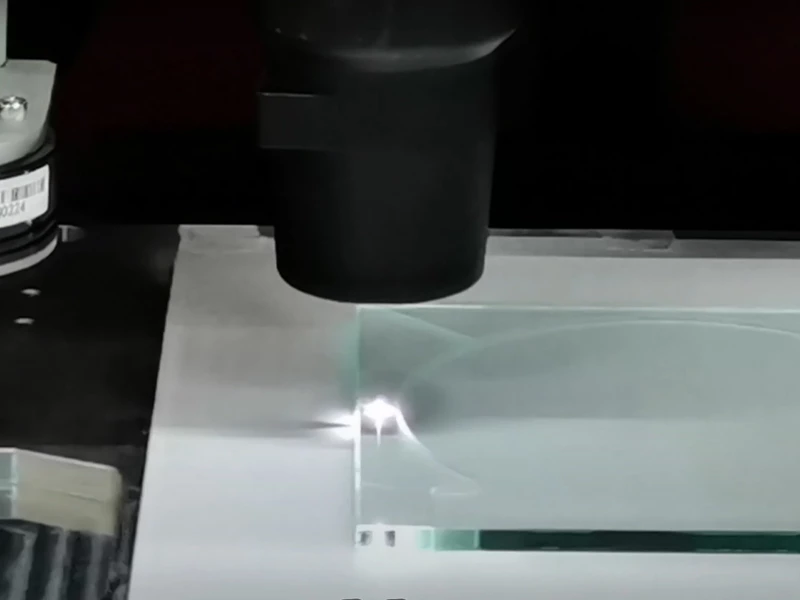

Laser Cutting Glass, But NOT CO2.

Cutting glass with CO2 lasers is a well-established practice, but the use of high-frequency MOPA fibers or high-speed lasers is gaining popularity. These cutting-edge technologies offer higher processing efficiency, greater precision, smoother and flatter cut edges, and less heat buildup on the substrate.

The use of high-speed laser to weld glass is a new technology that has not yet been applied on a large scale, which can be welded through the glass to weld the glass to another piece of glass or metal-plastic materials, and the weld seam shows a beautiful and neat frost. Its welding precision and quality consistency is better than the glass bonding process, and there is no adhesive consumption, currently in the spacecraft porthole, hyper car windshield and door window welding have been initially applied.

Related Cases

Want an un art handing video demonstration on specialized material? Looking for a solution to your specialized environment or automatic process demand?