Handheld Laser Welder

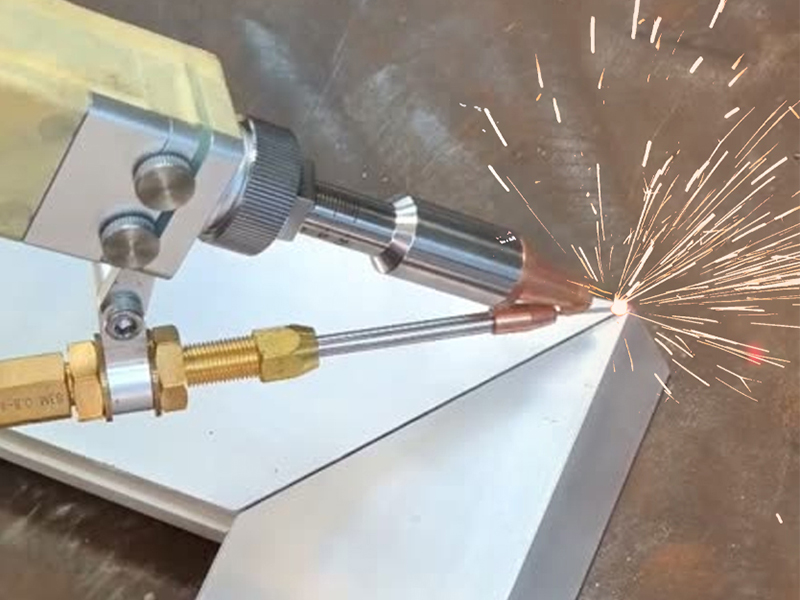

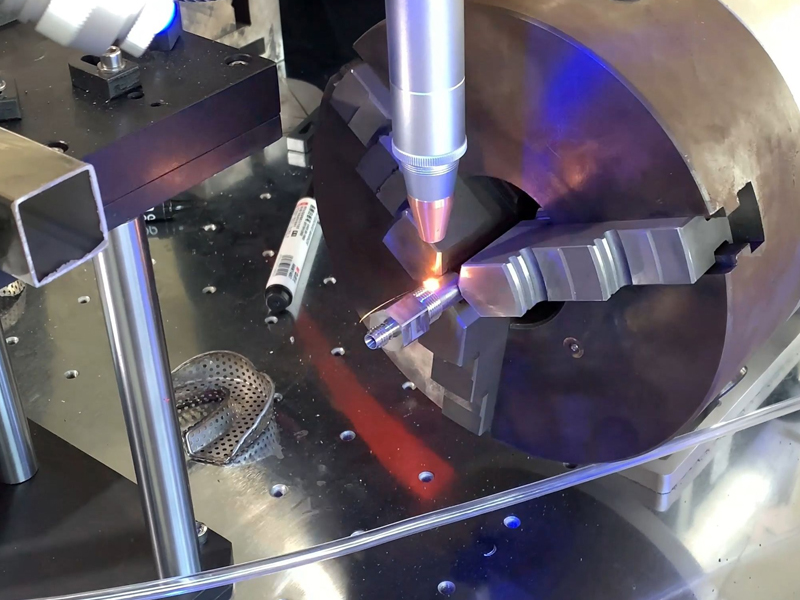

Since 2016, in response to demand from our marking machine customers, we have expanded into laser welding. To date, we offer a standard line of air-cooled and water-cooled handheld laser welding machines that can be configured to your exact needs in terms of the look of the machine, different brands or models of lasers, and handheld welding torches to ensure you get the most out of your welding job in real time and at a great price.

Our handheld welders offer excellent welding speed, accuracy and stability, providing reliable performance over long periods of time, whether in South Asia, the Middle East or tropical Africa. These welders are easy to use, require less heat than conventional TIG or MIG, require less skill than conventional TIG or MIG, and can be trained to achieve excellent weld quality and aesthetics. In addition, they can be switched between laser cutting and CW cleaning by changing the configuration of the handgun.

For product pricing, customization, or other inquiries:

Description

Technical data of our standardized handheld laser welding machines

Choose from our standard machines below and slide to the right for more information, or contact us for a solution.

| Typical Appearance | Cooling Method | Wire Feeding Dia. | Weld Depth per Side | Laser Type | Laser Wavelength | Laser Power | Power Tunability | Power Stability | Laser Beam Quality (BPP) | Power Supply | Operating Environment | Storage Environment |

| Air cooled | 0.8~2.0mm | Up to 4mm | CW/Modulated | 1080±10nm | 800W/1200W/1500W | 10~100% | ≤±2 % | ≤2.2mm x mrad (50μmQBH) | 100~240VAC, 50~60Hz, or 380VAC | 10~35℃ or 50~95℉, RH30~85% no condensation | 5~60℃ or 41~140℉, RH30~85% no condensation |

| Water cooled | 0.8~2.0mm | Up to 4mm | CW/Modulated | 1080±10nm | 1000W/1500W/2000W/3000W | 10~100% | ≤±1 % | ≤1.5mm x mrad (50μmQBH) ≤3.6mm x mrad (100μmQBH) | 10~40℃ or 50~104℉, RH10~85% no condensation | -10~60℃ or 14~140℉, RH10~85% no condensation |

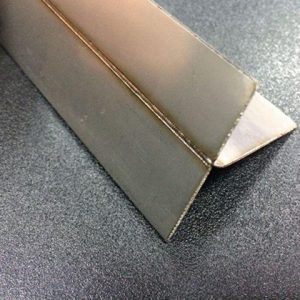

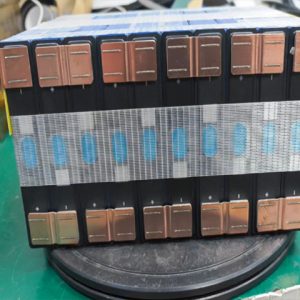

Welding Samples

Clients who chose our Laser Welding Machine.

FAQs about our Laser Welding Machine

Want an un art handing video demonstration on specialized material? Looking for a solution to your specialized environment or automatic process demand?