Handheld Laser Welding Machine: A Comprehensive Analysis of Its Applications

In recent years, handheld laser welding machines have become a game-changer in the world of metal fabrication and industrial joining. With the rising demand for precision, speed, and aesthetic quality in welding processes, these compact, efficient tools are becoming the preferred choice in many industries. Whether you’re a small business owner, a large-scale manufacturer, or an enthusiastic DIYer, understanding what a handheld laser welder can do may help you make a smarter investment.

In this article, we’ll explore what a handheld laser welding machine is, why it stands out from traditional welding equipment, where it’s typically used, and who can benefit the most from it.

What is a Handheld Laser Welding Machine?

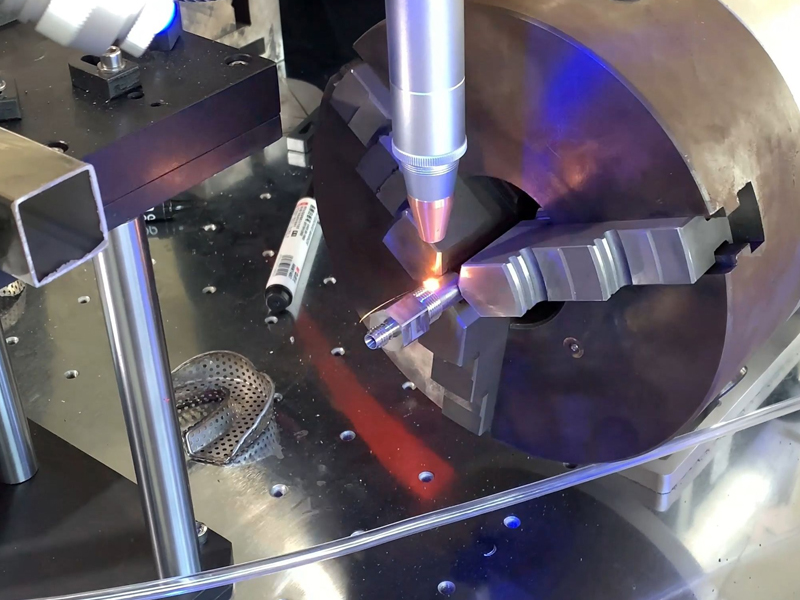

A handheld laser welding machine is a compact, portable device that uses focused laser beams to join metals with micron-level accuracy. Unlike traditional welding tools, it operates without direct contact with materials, minimizing heat distortion. Key components include:

- Fiber Laser Source: Typically 1000W–3000W for varied material thicknesses

- Ergonomic Welding Gun: Lightweight design (1.5–3 kg) for operator comfort

- Smart Control System: Real-time temperature monitoring and pulse modulation

How It Works:

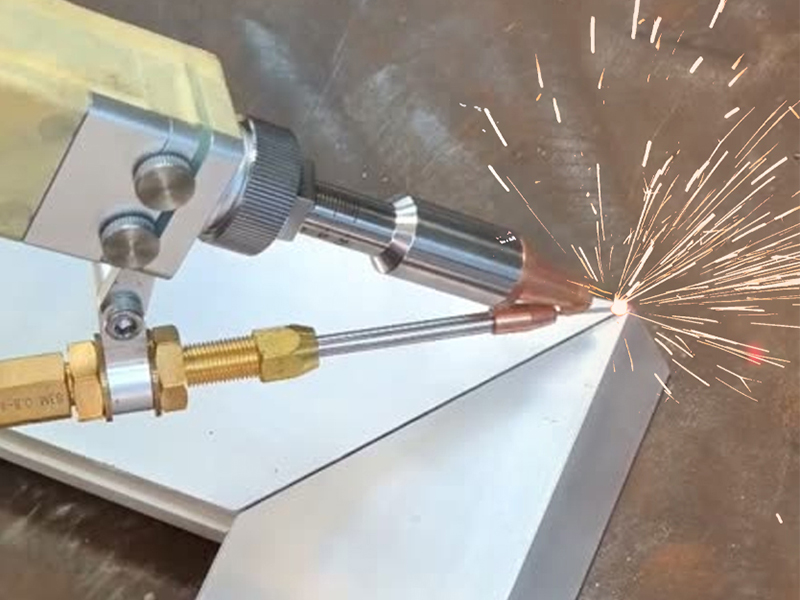

The laser beam melts the workpiece’s surface, forming a molten pool. A wire feeder (optional) adds filler material for reinforced joints. With spot sizes as small as 0.2mm, it achieves surgical precision impossible for conventional MIG/TIG welders.

Core Advantages of Handheld Laser Welding Machines

Why are so many companies switching to handheld laser welders? Here are some of the major advantages:

● High Welding Speed

Compared to traditional welding techniques, laser welding can be up to 2–10 times faster, significantly increasing productivity. Weld speeds reach 10 meters/minute for thin sheets (0.5mm stainless steel), slashing production time by 60% in appliance manufacturing. Energy consumption is 30% lower than plasma welding.

● Minimal Heat-Affected Zone (HAZ)

The precise energy control ensures less deformation and reduces the risk of damaging surrounding materials.

● Clean and Aesthetic Welds

No need for grinding or post-processing in most cases. The welds are smooth, clean, and professional-looking.

● Low Skill Barrier

Thanks to the intuitive operation, even novice operators can achieve quality welds after brief training.

● Versatility

These machines support a wide range of materials and welding positions, from flat surfaces to vertical seams and tight corners. From reflective copper (up to 8mm thick) to oxidation-prone aluminum alloys, handheld lasers handle diverse metals. Advanced models even weld dissimilar materials—stainless steel to titanium, for example.

● Cost-Effective in the Long Run

Although the initial cost may be higher, the reduced labor, consumables, and rework make them more economical over time.

Typical Application Areas of Handheld Laser Welding Machines

Handheld laser welders are widely adopted across various industries. Below are some of the most common application sectors:

Industrial Manufacturing

In manufacturing settings, laser welding is ideal for high-precision tasks. Applications include:

Automobile Manufacturing: Used for welding structural components and parts of car bodies, such as doors, chassis, and fuel tanks. Laser welding improves weld quality and production efficiency, and is suitable for a wide range of metal materials.

Hardware Industry: Applicable for manufacturing precision hardware parts, locks, tools, etc. It enables fine welding of materials like stainless steel and aluminum alloys.

Machinery Manufacturing: Performs excellently in welding machine frames and complex mechanical components, especially suitable for large, intricate, or irregularly shaped workpieces.

Home Improvement and Construction

With the growing popularity of metal furniture, aluminum window frames, and steel railings, construction companies and interior design firms are turning to handheld laser welders for:

Kitchen and Bathroom Fixtures: Used for welding stainless steel components such as sinks, faucets, and showerheads. The welds are both aesthetically pleasing and strong.

Doors, Windows, and Railings: Suitable for welding aluminum alloy doors and windows, as well as stainless steel railings, ensuring both weld strength and visual quality.

Advertising and Decorative Lighting: Applied in assembling large lightbox frames and decorative lighting fixtures. The welds are secure and do not affect surface appearance.

Electronics and Electrical Appliances

Precision is critical in the electronics sector, making laser welding a top choice for:

Electronic Components: Used in fields such as consumer electronics and automotive electronics for welding miniature components, circuit boards, and sensors, ensuring electrical performance and reliability.

Home Appliance Manufacturing: Applied in welding internal circuits and control modules of household appliances, enhancing the overall performance of the products.

Emerging and Niche Applications

Besides traditional sectors, handheld laser welding machines are being used in various niche fields, including:

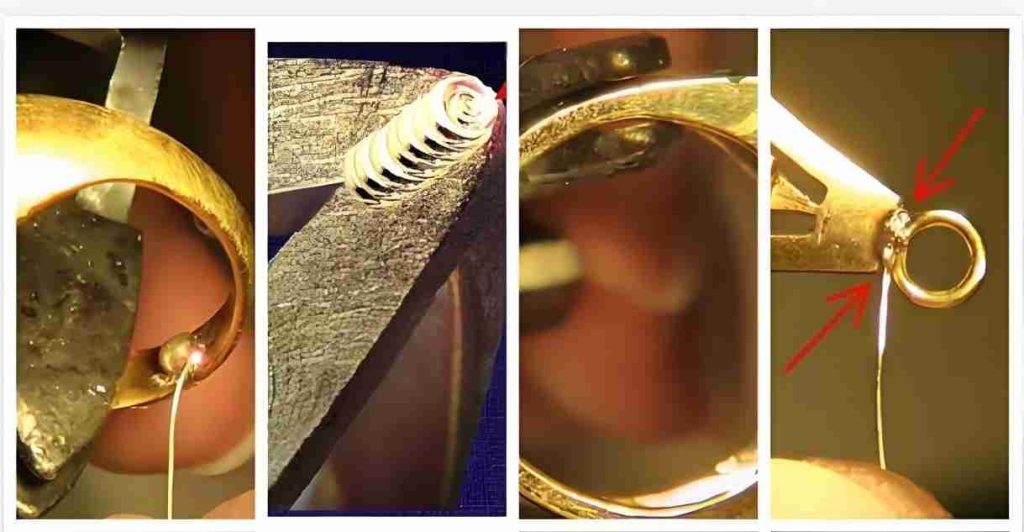

Jewelry: Used for welding small parts made of precious metals such as gold, silver, and platinum, avoiding the damage that traditional welding methods might cause to the materials.

Medical Devices: Suitable for welding medical-grade metals like stainless steel and titanium alloys, ensuring the safety and functionality of medical equipment.

New Energy: Plays a key role in the assembly of lithium batteries and the welding of solar cells, ensuring stable conductivity and optimal battery performance.

In addition, handheld laser welding is widely used in industries such as aerospace, shipbuilding, and mold manufacturing for welding complex components and performing on-site repairs.

Applicable Material Range for Handheld Laser Welding Machines

One of the major strengths of these machines lies in their broad material compatibility. Most handheld laser welding machines can effectively weld:

- Stainless steel

- Carbon steel

- Galvanized steel

- Aluminum and aluminum alloys

- Copper (with higher-end models)

- Titanium (selectively)

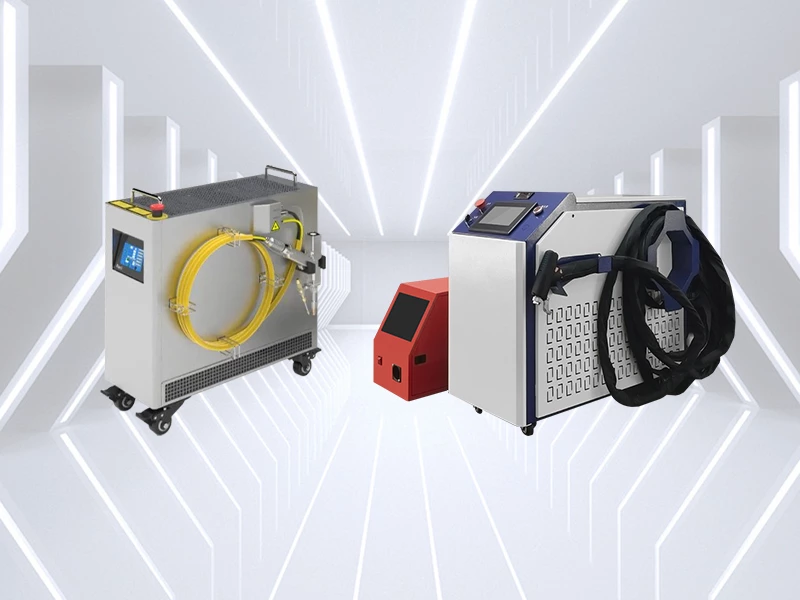

For example, in a china handheld laser welding machine, the power options (1000W, 1500W, 2000W) can determine how well the machine performs across different thicknesses and materials. Higher wattage models are often recommended for aluminum and copper due to their high thermal conductivity.

Do You Need a Handheld Laser Welding Machine?

Handheld laser welding machines are no longer futuristic tools exclusive to high-end factories—they have become a convenient, efficient, and powerful solution for industries and businesses of all sizes. With the ability to handle various materials, deliver aesthetically pleasing results, and minimize reliance on skilled labor, it’s no surprise that demand for handheld laser welders continues to surge.

Since 2016, Zixu has expanded into the laser welding field to meet the evolving needs of our marking machine customers. We now offer a range of standard air-cooled and water-cooled handheld laser welding machines, fully customizable to your specific requirements—whether it’s machine design, laser source brand/model, or welding gun type—to ensure you get the best welding results at a highly competitive price.

If you’re considering an upgrade or looking to streamline your welding operations, a handheld laser welding machine could be the smart investment your business needs. Feel free to contact us anytime for a professional quote.

Recommended Products