Handheld Scribe Marking Machine

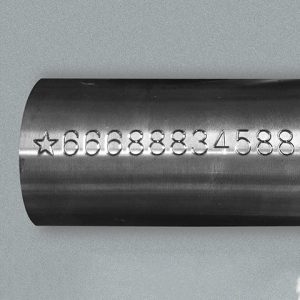

Our handheld pneumatic scribe markers use a hardened marking needle to “write” on the surface of the workpiece, creating a continuous line of consistent depth and width. Compared to spot marking, scribe marking does not vibrate the surface of the workpiece and reduces the number of impacts, resulting in significantly lower operating noise and higher quality permanent marks.

The hand-held scribe marking machine is widely used for marking luxury car frames, company storefronts, office signs, metal doors and other large customized products metal logos, etc. due to its unique marking effect and hard-to-imitate characteristics. Additionally, because they do not produce vibration or resonance, our hand-held marking machines are especially suited for marking large gas pipelines and other installations.

For product pricing, customization, or other inquiries:

Description

Technical Data of Our Handheld Scribe Marking Machine

Choose from our standard machines below and slide to the right for more information, or contact us for a solution

| Typical Appearance | Machine Type | Work Area | Marking Speed | Marking Depth | Controller | Air Supply | Marking Needle |

| Handheld | 150*90mm | 1~5cps or 5~100mm/s | 0.1~0.3mm for single write on steel, 1mm max. | Thorx6/Thorx7 PC based controller | 0.4~0.6MPa | Dia. 6mm & 8mm core for standard, or custom needles for specialized purpose. |

| Handheld | 150*90mm | 1~5cps or 5~100mm/s | 0.1~0.3mm for single write on steel, 1mm max. | Thorx6/Thorx7 touch screen controller | 0.4~0.6MPa | Dia. 6mm & 8mm core for standard, or custom needles for specialized purpose. |

Choose Control Software on Your Marking Demanding

Thorx-6 software are widely used in pin marking industry with suffice functions for English environment, however, if you need more language support, check the table for right one, or ask for advice.

| software |  Thorx-6 |  Thorx-7 |  Kingmark-8 |

| Language | English | English | All language |

| Marking Content | English fonts (letters & numbers), vector graphics | English fonts & dot-fonts, vector graphics, Datamatrix (QR code) | All language fonts & dot-fonts, vector graphics, Datamatrix (QR code) |

| Font Format | SHX, SLF, TTF, SHP | SHX, SLF, TTF, SHP | SHX, SLF, TTF, SHP |

| Graphic Format | PLT, SLG, WMF, EMF, DWG, DXF | PLT, SLG, WMF, EMF, DWG, DXF | PLT, SLG, WMF, EMF, DWG, DXF |

| Controller Configuration | Touchscreen controller or industrial PC controller with USB & RS232 connection. | Touchscreen controller or industrial PC controller with USB & RS232 connection. | Touchscreen controller or industrial PC controller with USB & RS232 connection. |

| Touchscreen Size | 7’’ | 7’’ | 10.1’’ |

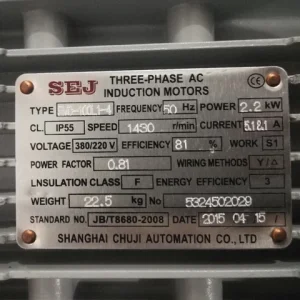

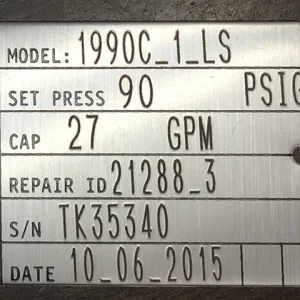

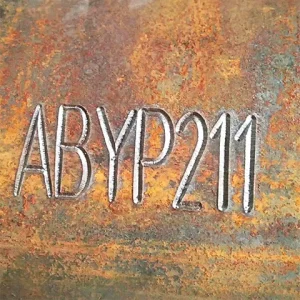

Marking Samples

Clients who chose our handheld scribe marking machine.

FAQs about our handheld scribe marking machines.

Want an un art handing video demonstration on specialized material? Looking for a solution to your specialized environment or automatic process demand?