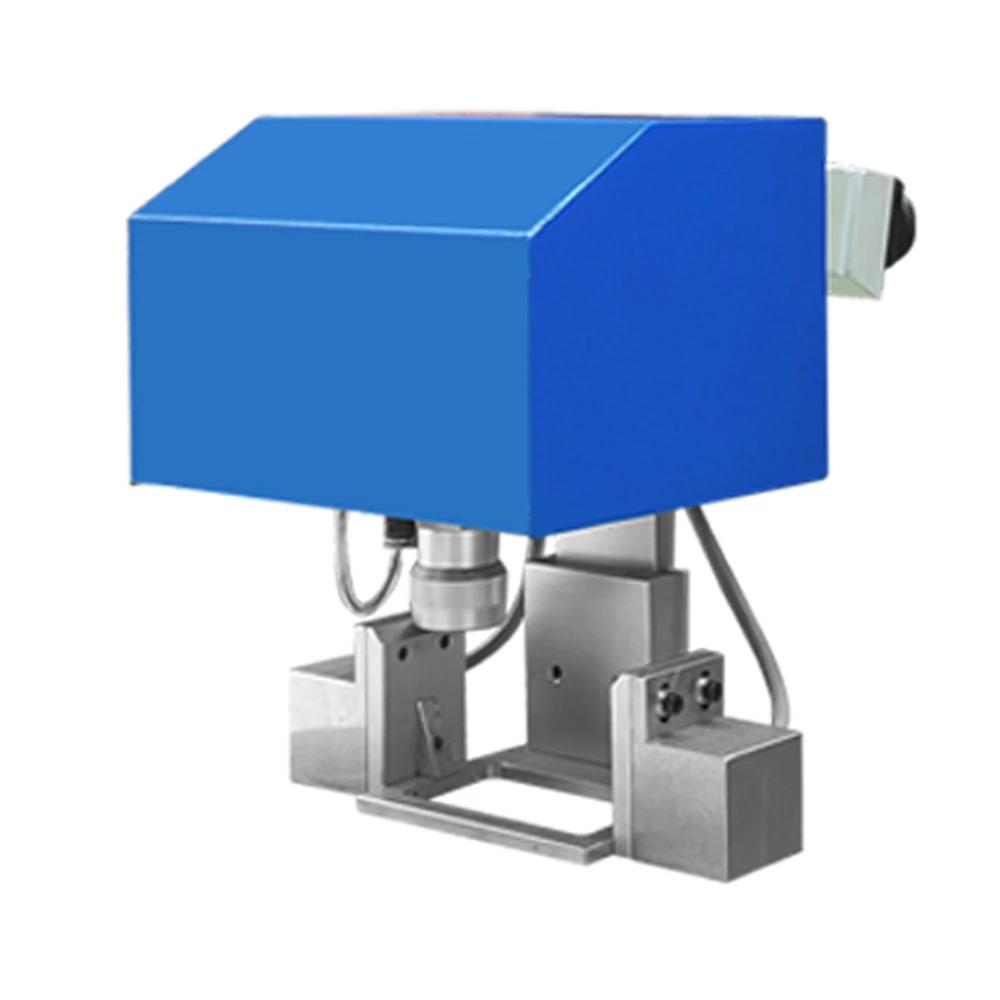

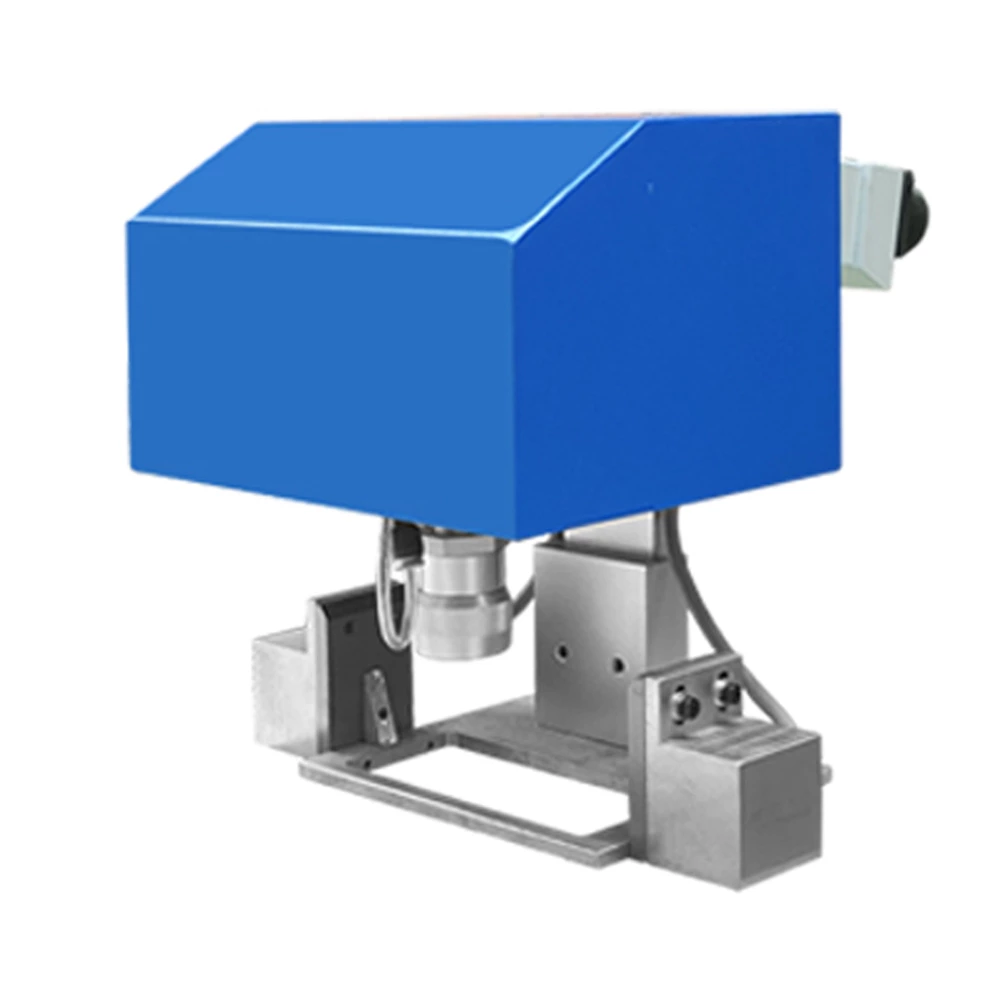

Handheld Pneumatic Dot Peen Marking Machine

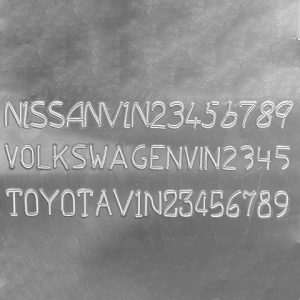

Our marking business started in 2006, initially focusing on the marking and re-marking of vehicle identification numbers (VIN), which remains a core part of our global business today. VIN is a unique identification code for a vehicle, usually consisting of 17 characters, including the World Manufacturer Identifier (WMI), the Vehicle Description Section (VDS) and the Vehicle Identifier Section (VIS).

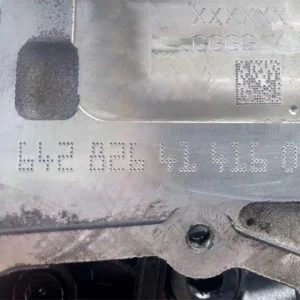

Zixu handheld pneumatic dot peen VIN marking machine is widely used in the re-marking work of traffic management agencies in various countries, thanks to its high-rigidity marking needle, which can mark with an accuracy of 0.3mm in a single operation and present a clearly visible mark within seconds. In addition, our marking equipment is known for its excellent durability, and many of the equipment have been in service for more than 10 years in the hands of customers and still maintain excellent performance.

For product pricing, customization, or other inquiries:

Description

Technical data of our standardized handheld pneumatic dot peen marking machines

Choose from our standard machines below and slide to the right for more information, or contact us for a solution.

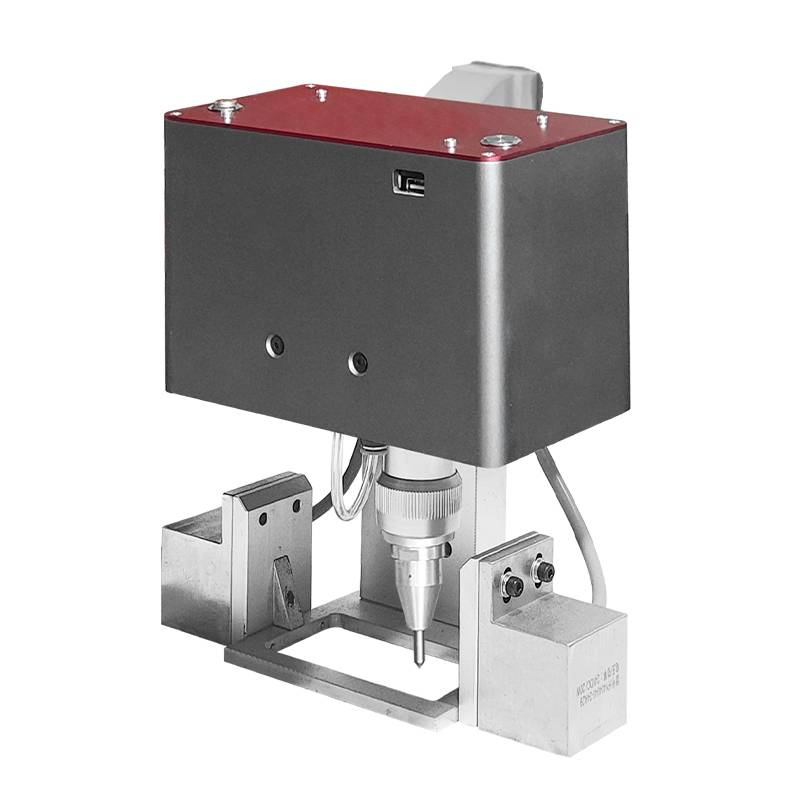

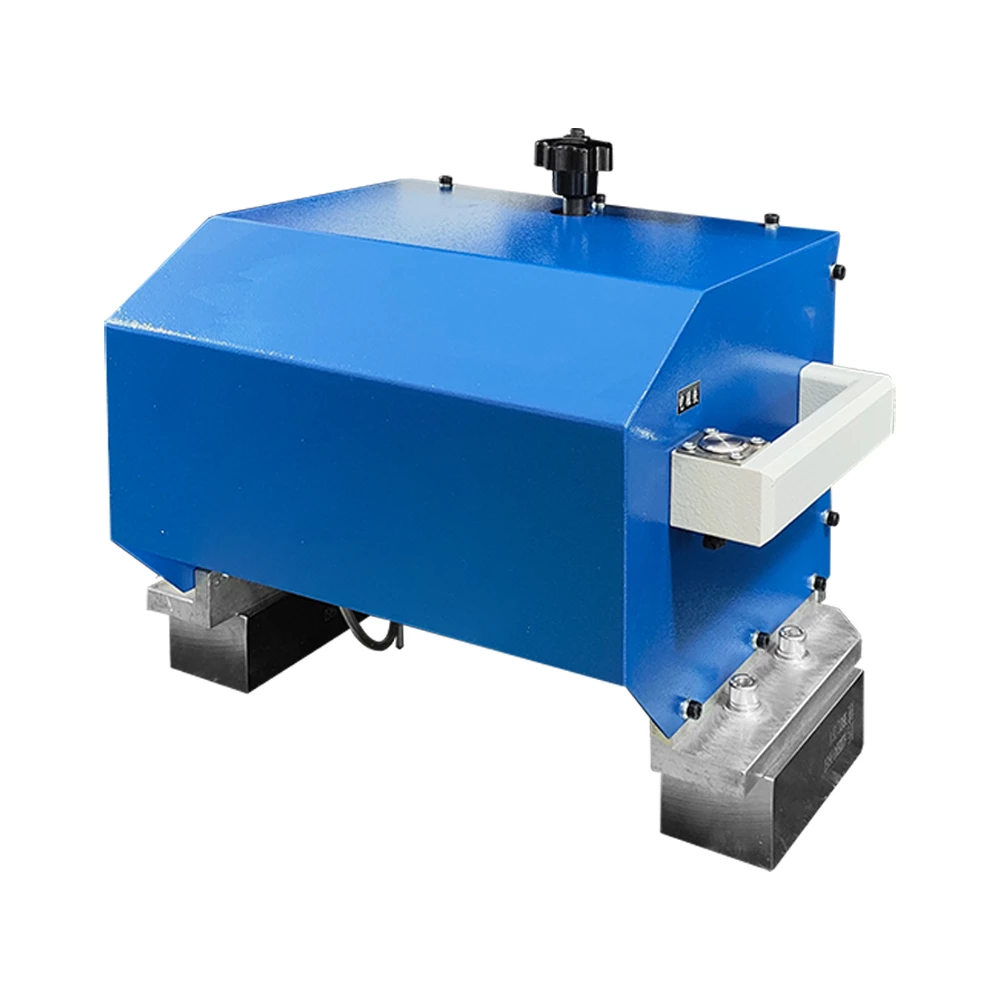

| Typical Appearance | Machine Type | Work Area | Marking Speed | Marking Depth | Controller | Air Supply | Marking Needle |

| One-handed | 80*40mm | 1~5cps or 5~100mm/s | 0.1~0.3mm for single write on steel, 1mm max. | Thorx-6/Thorx-7/Kingmark-8 | 0.4~0.6MPa | 3mm V60 & 4mm V80 for standard, or custom needles for specialized purpose. |

| One-handed | 120*50mm | Thorx-6/Thorx-7/Kingmark-8 | ||||

| One-handed | 110*20mm | Thorx-6/Thorx-7/Kingmark-8 | ||||

| All-in-one | 110*20mm | Kingmark-3 | ||||

| One-handed | 130*30mm | Thorx-6/Thorx-7/Kingmark-8 | ||||

| All-in-one | 130*30mm | Kingmark-3 | ||||

| Two-handed | 140*50mm | Thorx-6/Thorx-7/Kingmark-8 | ||||

| Two-handed | 140*80mm | Thorx-6/Thorx-7/Kingmark-8 | ||||

| Deep Marker | 140*80mm | 0.3~0.5mm for single write on steel, 2mm max. | Thorx-6/Thorx-7/Kingmark-8 |

Choose control software on your marking demanding

Thorx-6 software are widely used in pin marking industry with suffice functions for English environment, however, if you need more language support, check the table for right one, or ask for advice.

Thorx-6 |  Thorx-7 |  Kingmark-3 |  Kingmark-8 | |||||

| UI Language | English | English | All language | All language | ||||

| Marking Content | English fonts (letters & numbers), vector graphics | English fonts & dot-fonts, vector graphics, Datamatrix (QR code) | English fonts & dot-fonts, vector graphics, Datamatrix (QR code) | All language fonts & dot-fonts, vector graphics, Datamatrix (QR code) | ||||

| Font Format | SHX, SLF, TTF, SHP | |||||||

| Graphic Format | PLT, SLG, WMF, EMF, DWG, DXF | |||||||

| Controller Configuration | Touchscreen controller or industrial PC controller with USB & RS232 connection. | |||||||

| Touchscreen Size | 7’’ | 10.1’’ | ||||||

Marking Samples

Clients who chose our handheld pneumatic dot peen marking machines

FAQs about our pneumatic dot peen marking machines

Want an un art handing video demonstration on specialized material? Looking for solution of your specialized environment or automatic process demanding?