High-Precision Pneumatic Engraving Solution for VIN Codes

With the rapid advancement of industrial technology, the demands for product identification and traceability have been increasing across various industries. In the automotive manufacturing industry, the Vehicle Identification Number (VIN), as the unique identifier of a vehicle, plays a crucial role in vehicle registration, maintenance, insurance, and recalls. To meet this demand, pneumatic VIN marking machines have emerged as an indispensable part of modern automotive manufacturing.

This article will delve into the significance of VIN codes, explore the principles of pneumatic engraving for VIN marking, and discuss the advantages and considerations for selecting and using pneumatic VIN code marking machines.

What is a Vehicle Identification Number (VIN)?

A Vehicle Identification Number (VIN) is a unique 17-character alphanumeric code assigned to every vehicle. Often referred to as a vehicle’s “identity card”, the VIN provides a permanent and unique identifier for each vehicle. Composed of a World Manufacturer Identifier (WMI), Vehicle Description Section (VDS), and Vehicle Identification Section (VIS), the VIN encodes a wealth of information about the vehicle, including its country of origin, manufacturer, year of production, production sequence, and assembly plant. This unique combination of characters ensures that no two vehicles share the same VIN, even over a 30-year production span.

Applications of VINs

The VIN is used for a variety of purposes, including:

- Vehicle identification: It uniquely identifies each vehicle, preventing duplication and errors.

- Vehicle tracking: VINs are used to track a vehicle’s production, distribution, and ownership history.

- Safety recalls: Manufacturers can use VINs to identify vehicles that require safety recalls.

- Insurance and theft recovery: Law enforcement agencies rely on VINs to recover stolen vehicles and insurance companies use them for underwriting and claims processing.

Common Locations of VINs

VINs are typically located in several places on a vehicle to ensure redundancy and prevent damage. Common locations include:

- Dashboard: On the driver’s side, often visible through the windshield.

- Door jamb: On the driver’s side door, near the latch.

- Engine compartment: On a metal plate or component within the engine bay.

- Vehicle certification label: A sticker affixed to the vehicle, usually on the driver’s side door jamb.

Quality Requirements for Vehicle VIN Markings

VIN markings must meet specific quality standards to ensure readability and durability. Key requirements include:

- Legibility: Characters must be clear, distinct, and easily readable.

- Permanence: Markings must withstand environmental conditions, such as exposure to chemicals, temperature extremes, and wear and tear.

- Accuracy: The VIN must be accurately reproduced to avoid errors in identification.

- Compliance: Markings must comply with industry standards and regulations.

How Pneumatic Engraving Works for VIN Codes?

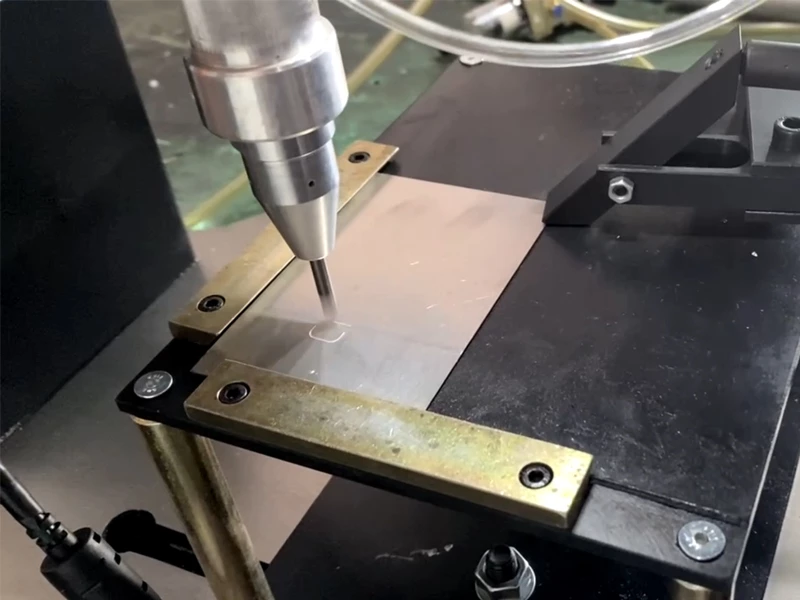

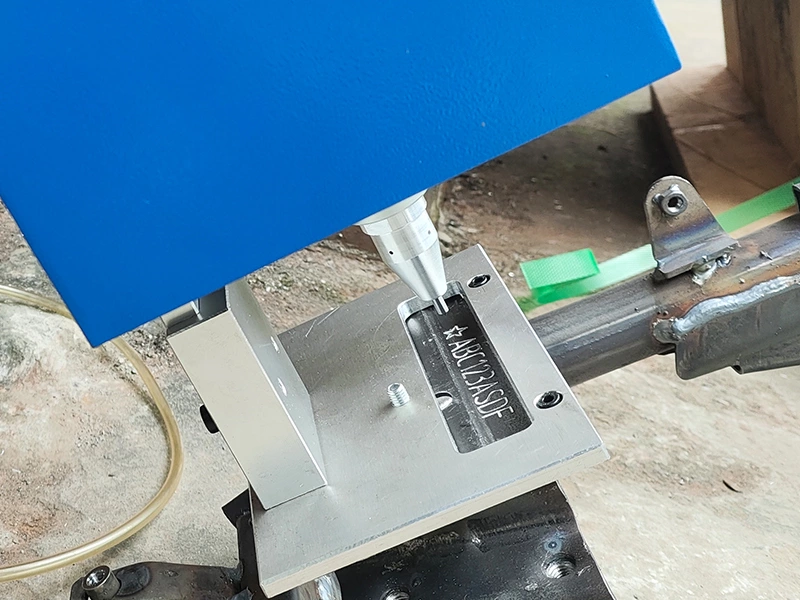

Pneumatic engraving works by utilizing a pneumatic engraver that, driven by compressed air, uses a hard alloy or diamond stylus to inscribe characters, logos, and other markings onto a material’s surface. Specifically, the pneumatic engraver employs a computer-controlled printing needle that undergoes high-frequency impact motions powered by compressed air, thereby imprinting markings of a certain depth onto the workpiece.

By watching the following video, we can more intuitively understand the operation process of pneumatic dot-peen marking vehicle VIN code.

In automotive manufacturing, pneumatic engraving is commonly used for marking vehicle identification numbers (VINs), engine numbers, and other identifiers. The pneumatic engraver creates clear VINs on metal surfaces through high-frequency impact, ensuring that each character meets depth and clarity standards. This technology not only enhances the durability of markings but also guarantees the accuracy and traceability of vehicle information.

Advantages of Pneumatic Engraving for Automotive VIN Code Marking

· High Precision and Consistency: Pneumatic engraving machines can complete intricate engraving tasks in a short amount of time while maintaining high repeatability, ensuring that each mark is consistent in position and depth to meet high-standard production requirements.

· Low Noise: Compared to traditional dot-pin marking machines, pneumatic engraving machines produce less noise during operation, making them ideal for applications that require a quiet working environment.

· Adjustable Engraving Depth: The engraving depth of pneumatic engraving machines can be adjusted according to specific needs, making them suitable for applications with special requirements for engraving depth.

· Wide Material Compatibility: Pneumatic engraving machines can easily handle various materials such as metals, plastics, wood, and stone, making them widely applicable in multiple industries.

· Excellent Imprinting Effect: Pneumatic engraving machines produce smooth lines and clear characters, and the imprinting effect remains good even after spraying treatment, making them suitable for marking requirements of most metal and non-metal workpieces.

· Easy Operation: Users can achieve precise engraving of complex patterns through simple settings, eliminating the need for highly skilled operators and reducing labor and training costs.

· Low Maintenance Cost: Pneumatic engraving machines use pneumatic drive, avoiding complex mechanical transmission components, thereby reducing daily maintenance and long-term maintenance costs.

· Environmentally Friendly and Energy-Efficient: Using compressed air as a power source, pneumatic engraving machines do not produce pollution during operation, meeting the green and environmentally friendly requirements of modern industrial production.

Selection and Usage of Pneumatic VIN Code Marking Machines

When selecting a pneumatic chassis number marking machine, users should comprehensively consider their production needs, workpiece materials, marking requirements, and other factors. At the same time, users should also compare and select equipment based on factors such as brand, performance, and price.

When using a pneumatic chassis number marking machine, users should strictly adhere to the operating procedures and safety regulations to ensure the normal operation of the equipment and the safety of operators. In addition, users should regularly maintain, inspect, and troubleshoot the equipment to ensure its long-term stable operation.

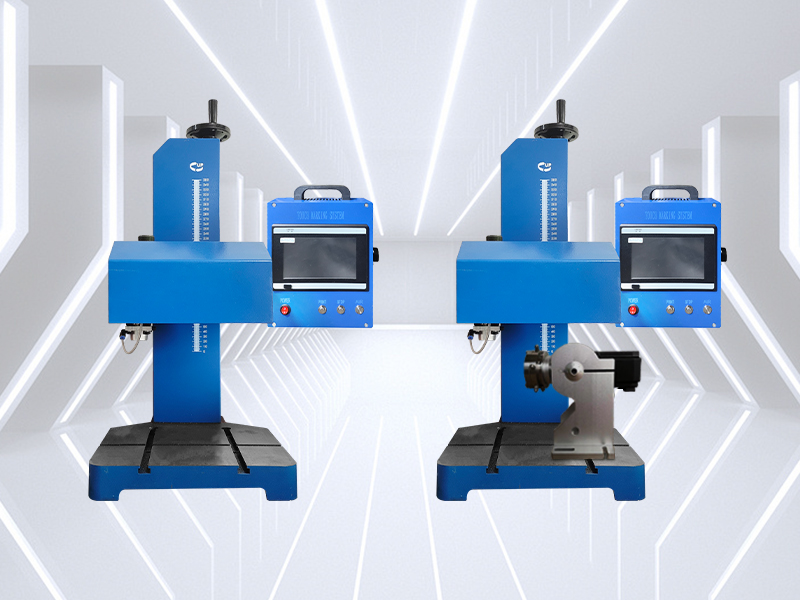

As a leading provider of pneumatic dot peen marking machines, Zixu has developed a full range of models specifically designed for metal engraving, from standard handheld units to fully customized heavy-duty automated production models.

Our best-selling marking machines are widely used in the automotive industry for manually marking VINs, chassis numbers, and engine numbers that are too large or heavy to move. They offer smooth marking results, support OEM fonts, and are easy to operate, allowing a single operator to complete the process from input to marking within minutes.

To learn more about our equipment in the automotive industry, please click here.

Recommended Products