Home Appliance & Consumer Electronics

The rapid development of the home appliance and consumer electronics industry over the past half century has revolutionized human life and consumption habits, and in addition to mass production, the industry is placing new demands on quality traceability, personalization and flexible production. Over the years of working with many industry brands, we have continued to develop new automation technologies for pin marking, laser marking, engraving, soldering and cleaning to meet their demanding needs and those of the end consumer.

Technologies For Home Appliance & Consumer Electronics

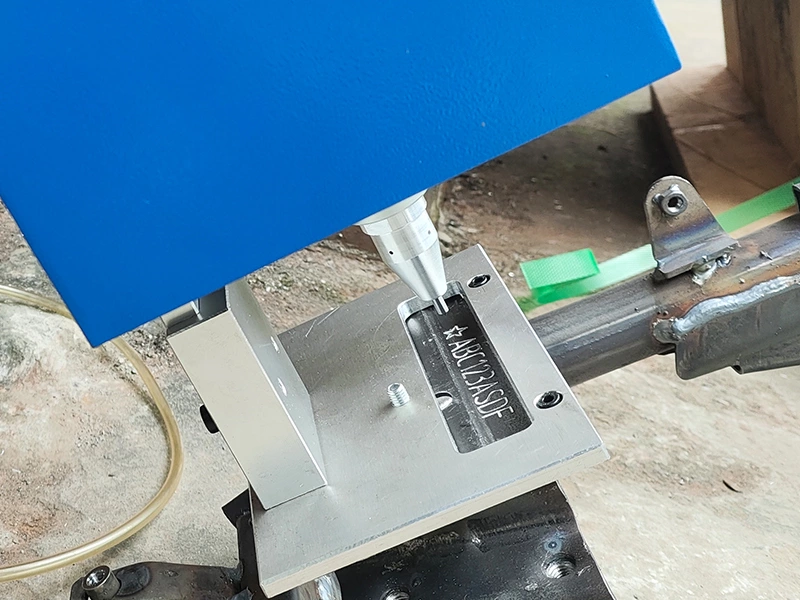

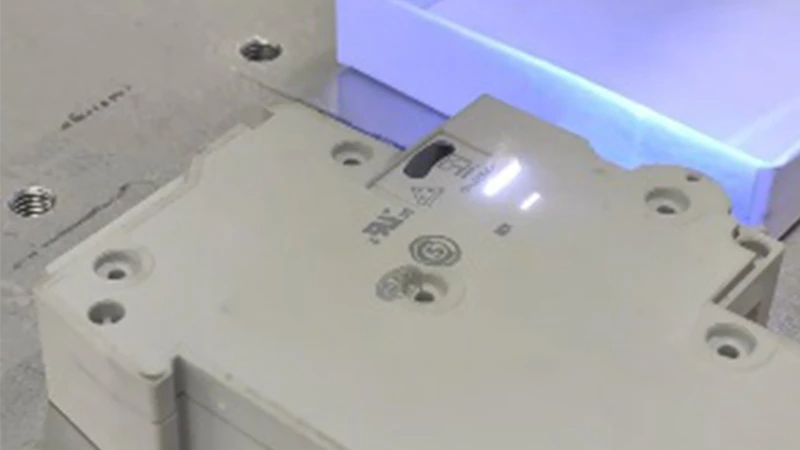

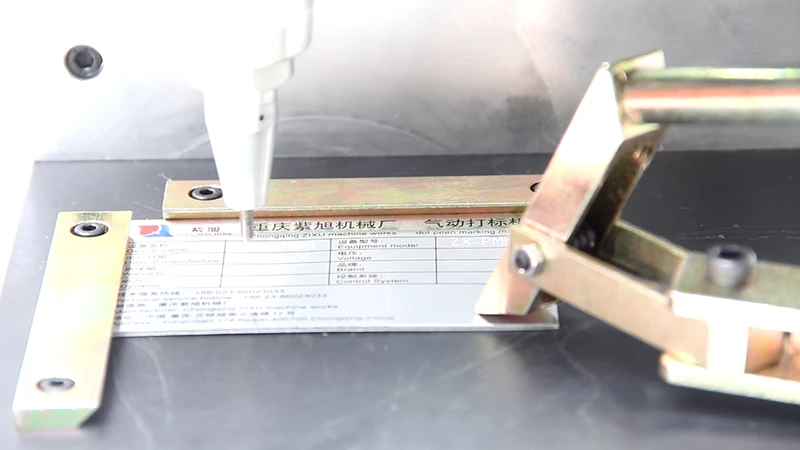

Traditional peen marking is gradually being replaced by lasers in today’s appliance and consumer electronics applications. However, the use of peen marking for quality tracking of metal products such as production machine nameplates, compressor components, heat pipes, etc., is a common application. In addition, some high-end customers use scribing machines for decorative metal panels or housings on equipment to achieve unparalleled aesthetic engraving.

- Beautiful: our peen marking machine offers a smooth mark edge and keeps in primary color of metal, especially by scribe, and no damage or burn on environmental surfaces.

- Fast: to mark with the same specific depth, such as 0.3mm, our peen marking machine is 8~10X faster than a 100W fiber laser system;

- Depth: our peen marking machine offers 0.1~0.3mm depth in one pass, and is able to precisely repeat for deeper marks;

Laser engraving or marking is the most common equipment we manufacture and supply to this industry, from metal nameplates on production machinery, to quality traceability barcodes or QR codes on all types of metal, plastic, silicone and glass product components; to manufacturer information, readability instructions, serial numbers on packaging; to personalized markings, etc., all can be done with laser.

- Quiet: laser marking of metal also generates noise especially deep engraving, but this is negligible compared to the peen marking process;

- Accuracy: Laser marking can mark metal in extremely small size, such as 0.03mm line width characters or graphics, which are impossible for peen marking;

- Visibility: Using MOPA fiber or UV laser for laser annealing instead of engraving for black or other color marking on metal workpiece with high contrast.

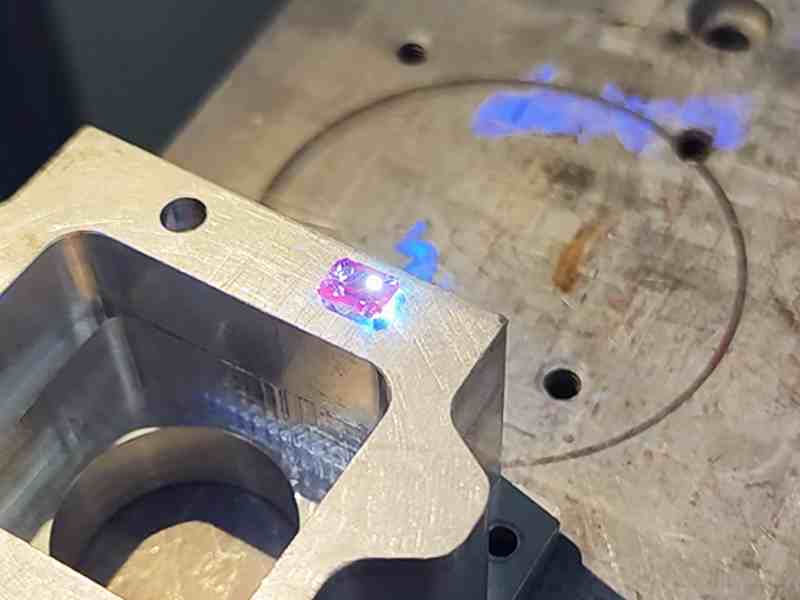

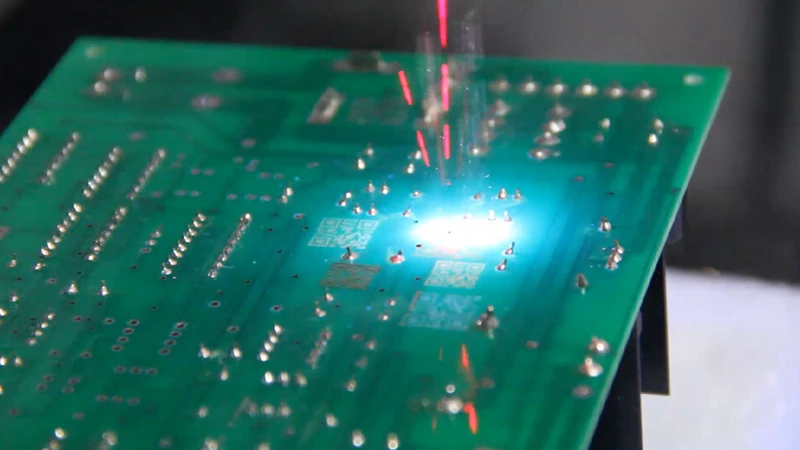

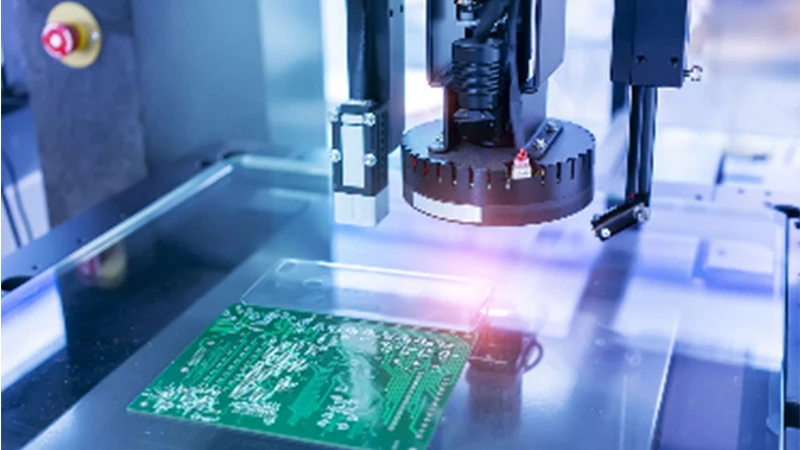

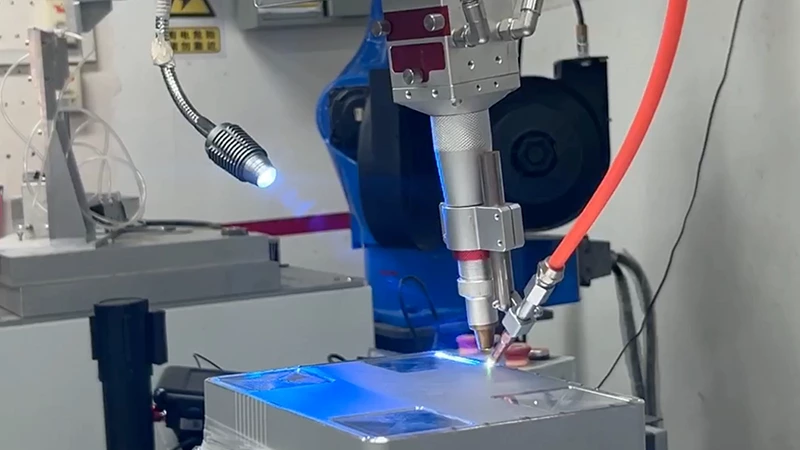

The home appliance and consumer electronics manufacturers have a variety of welding needs, whether it is the repair of injection molds, PCB board and batteries wiring and assembly, product metal shell and structural components are commonly used laser welding. Our customers in these industries often have large production volumes and highly automated production lines, providing us with a wealth of automation experience to meet your needs.

- Reliable: we use precise laser source to produce extremely small spots and weld marks with 24*7 working capability;

- Efficiency: we offer high-speed automated welding solutions to ensure stable welding process speed and avoid the bottleneck of production ramp-up;

- Economic: our automated welding process is simple and accurate, and can be customized with CCD visual inspection to minimize scrap and rework costs.

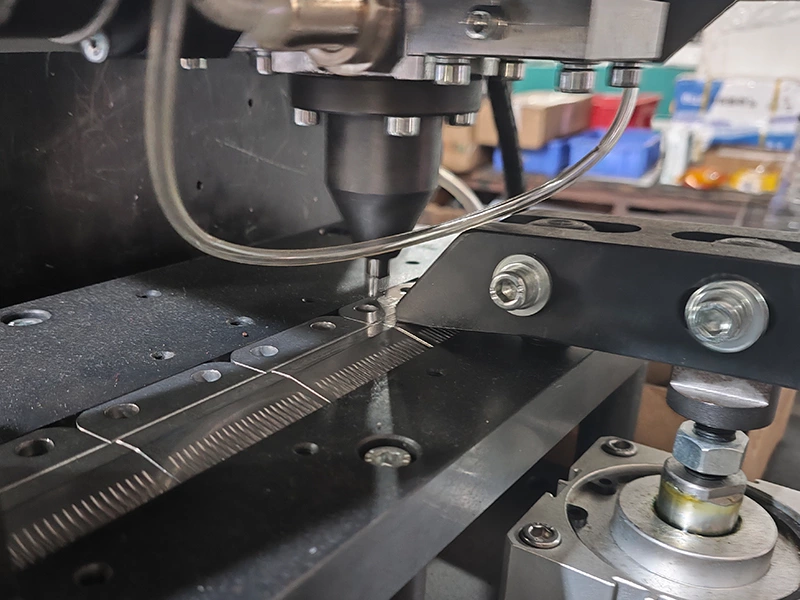

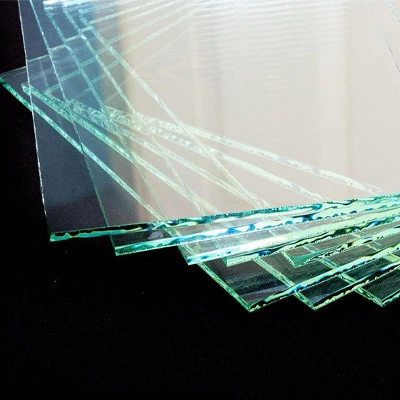

Unlike the CO2 laser cutters commonly used in other industries, there is a trend in the home appliance and consumer electronics industries to use UV laser cutters to cut and drill PCBs, glass or ceramics with greater precision and minimal carbonization to ensure yield. In addition to precision UV laser cutting, some home appliance or consumer electronics brands are also using fiber laser cutters to cut sheet metal to increase flexibility in the production of multiple products.

- Flexibility: Using our UV cutter can dramatically expand your ability to define products for design development and production;

- Reliable: we use precise laser source to produce extremely small spots and weld marks with 24*7 working capability;

- Economic: If your product needs to be upgraded with new features, etc., it can be installed or replaced by quickly fabricating small chip stacks rather than reinventing the wheel.

Explore Our Machines For Home Appliance & Consumer Electronics

Both the appliance and consumer electronics industries use plastic injection molding to produce structural components, housings, interface panels, and more. For quality traceability, these parts are often marked with barcodes or QR codes using fiber optics or UV lasers. In addition, laser marking of asset management nameplates for various types of production equipment such as injection molding machines, robots, nailers, packaging machines, and other types of equipment and tools is equally important and common.

In addition to quality traceability information, it has become a trend to use lasers to print detailed, high-contrast information such as logos, manufacturer information, instructions for use, etc. on the outer surfaces of materials such as metal, wood, plastics, glass and ceramics used in home appliances or consumer electronics. Using laser marking instead of inkjet and screen printing reduces ink consumption and improves production economics over the product life cycle.

In addition to laser marking, traditional needle marking of nameplates is also popular for the above types of equipment. Although a bit noisier, these machines can permanently mark metal nameplates faster and deeper than lasers. In addition, some high-end brands are also interested in the unique marking effect of the marking machine for decorative panels, such as logo marking.

The increasing density of integrated circuits in modern home appliances and consumer electronics products, while providing consumers with better performance and more functionality, also places higher demands on precision soldering. We offer a wide range of precision automated platform welding and galvo welding solutions, from CW to QCW to MOPA lasers, to meet the requirements of various metal materials and welding precision.

In addition to the advanced automated welding mentioned above, we also offer high-precision YAG laser welding machines equipped with both optical and CCD electron microscopes. For example, the desktop YAG laser welding machine is used for jewelry welding, but also for manual welding of PCB components for small and medium-sized customers. We also have a variety of platforms for repairing injection molds.

Related Cases

Want an un art handing video demonstration on specialized material? Looking for a solution to your specialized environment or automatic process demand?