How Handheld Metal Laser Welders Simplify Complex Welding Jobs in Construction and Repair

Welding is an essential process in construction and repair. Traditionally, welding was a highly skill-dependent and physically demanding task. However, with technological advancements, especially in laser technology, the emergence of handheld metal laser welders has simplified many complex welding jobs, making them faster, more accurate, and more versatile.

What is Metal Laser Welding Machine?

A metal laser welding machine is a cutting-edge tool that uses a concentrated laser beam to join metal pieces together. The laser beam generates intense heat, melting the edges of the metals to form a strong, seamless bond. Unlike traditional welding techniques that rely on consumable electrodes, filler materials, or extensive manual effort, laser welding leverages focused light energy to achieve precise and efficient welds.

These machines come in various types, with handheld models being particularly popular for their versatility and ease of use. The portability of handheld laser welders makes them ideal for a wide range of applications, from industrial construction to intricate repair jobs. By offering high precision, minimal heat distortion, and a cleaner weld finish, metal laser welding machines have revolutionized the welding industry, enabling professionals to tackle complex jobs with greater accuracy and speed.

A laser marking machine generates a high-intensity laser beam from a laser source. This beam is then manipulated through an optical system, including mirrors and lenses, to focus the beam onto the surface of the material to be marked.

When the laser beam strikes the material’s surface, the material absorbs a portion of the laser energy, causing the surface temperature to rise and resulting in a phase change or ablation, forming a permanent mark. This mark can be text, graphics, barcodes, or other patterns and is characterized by its durability, clarity, and resistance to fading.

How Handheld Metal Laser Welders Work?

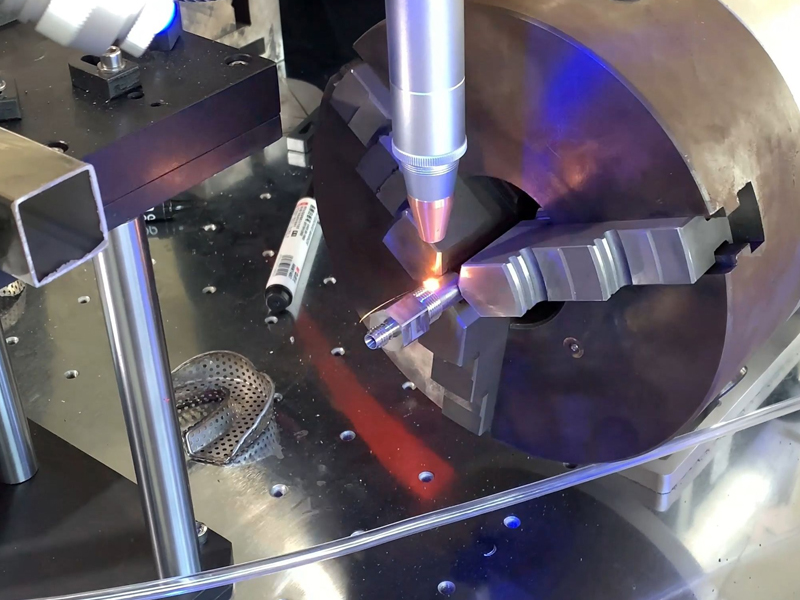

Handheld metal laser welders operate using a focused laser beam to join metal surfaces with precision and efficiency. This advanced welding process relies on the high-intensity energy of a fiber laser to generate heat and create a seamless bond between materials. Here’s how it works in detail:

- Laser Generation: The system utilizes a fiber laser source to create a highly concentrated beam of light. This beam is transmitted to the handheld welding head through flexible fiber optic cables, enabling seamless maneuverability and ease of use.

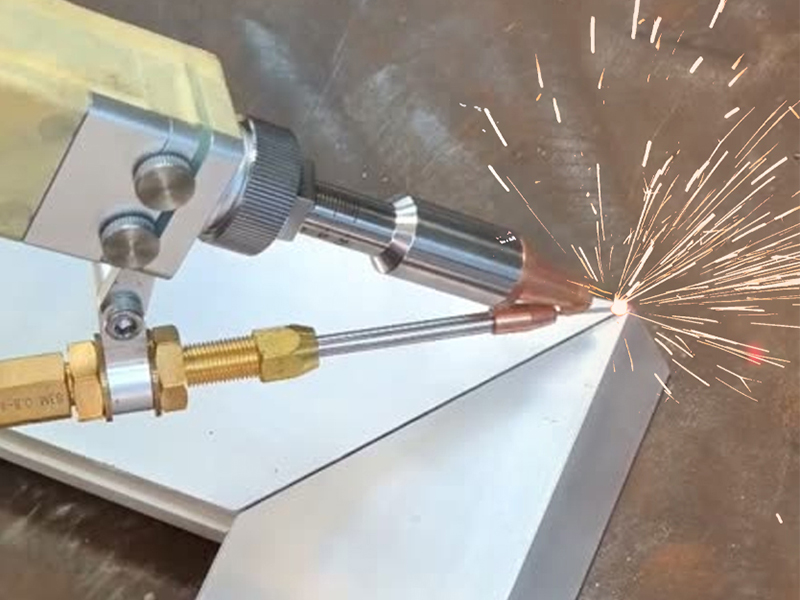

- Targeting and Focus: The handheld welding head features a precision lens that concentrates the laser beam onto a designated point on the metal surface. This focused targeting ensures the laser’s energy is directed precisely where it’s needed, delivering clean, accurate, and high-quality welds.

- Melting and Joining: The concentrated laser beam heats the metal at the target point until it reaches its melting temperature, creating a molten pool. As the laser progresses along the joint, the molten material merges to form a robust and seamless weld. This process often eliminates the need for filler materials, though they can be incorporated if required for specific applications.

- Cooling and Solidification: After the laser moves past the weld area, the molten metal cools and solidifies rapidly, producing a strong and durable joint with minimal distortion. The quick cooling process helps preserve the weld’s structural integrity and strength.

- Optional Features for Versatility: Many handheld laser welders come with adjustable settings for power, speed, and beam focus, making them versatile for different materials and thicknesses. They may also include features like wobble welding, which slightly oscillates the beam to improve weld width and quality for certain applications.

This precise, contact-free welding technique enables handheld laser welders to tackle complex tasks with outstanding accuracy and speed, while significantly reducing the risk of damage to surrounding materials. Their efficiency and versatility have made them the go-to solution for construction, repair, and a variety of industrial applications.

Benefits of Using Handheld Metal Laser Welder

Handheld metal laser welders have become a preferred choice for professionals in construction and repair due to their unique capabilities. Here are the five most important benefits, explained in greater detail:

Exceptional Precision and Accuracy

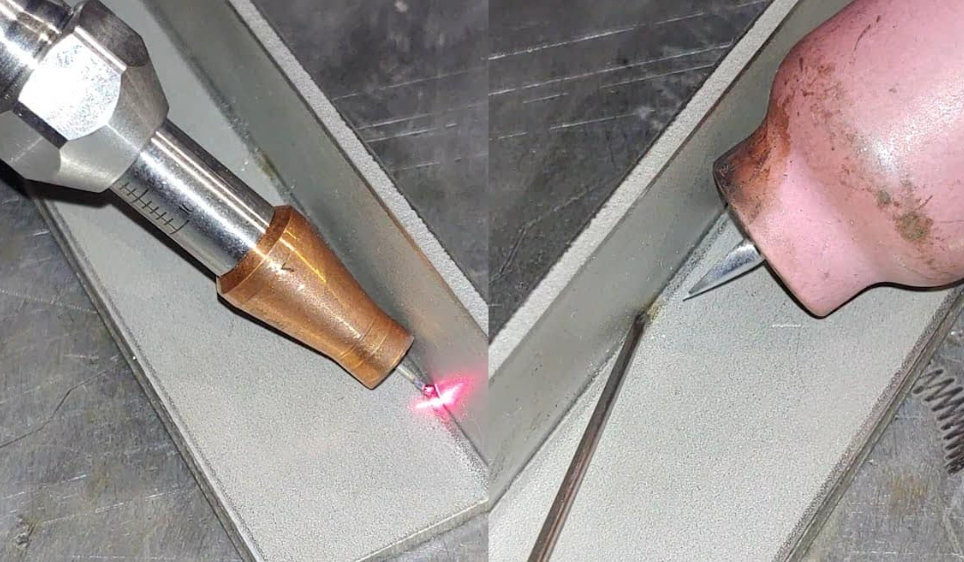

Handheld metal laser welders offer unmatched precision in welding operations. The concentrated laser beam enables pinpoint accuracy, making it effortless to weld small, intricate components or tackle complex joints. This level of precision ensures clean, defect-free, and structurally robust welds

- Welders can produce tight, consistent seams even on delicate or irregular materials, making these tools perfect for applications like automotive repairs, thin sheet metal projects, and high-end construction work.

- Precision welding minimizes the need for rework, enhances overall product quality, and significantly reduces material waste.

High Speed and Efficiency

Handheld laser welders deliver exceptional speed, significantly cutting down the time needed for welding tasks. The laser’s concentrated energy melts and fuses metals almost instantaneously, enabling faster passes compared to traditional welding methods.

- Welding jobs are completed in a fraction of the usual time, enhancing productivity in workshops and on construction sites.

- Increased welding speed reduces labor costs and accelerates project timelines, making it particularly valuable for large-scale construction and repetitive repair tasks.

Minimized Heat-Affected Zone (HAZ)

A key advantage of handheld laser welders is their ability to concentrate heat precisely on the welding area, minimizing its impact on the surrounding material. This results in a significantly smaller heat-affected zone compared to traditional methods like MIG or TIG welding.

- Materials maintain their original properties, reducing the likelihood of warping, cracking, or discoloration.

- This is especially important when working with thin or heat-sensitive materials, such as aluminum or stainless steel, where excessive heat can weaken the material and compromise its structural integrity.

Minimal Cleanup and Post-Weld Work

Laser welding produces clean, precise welds with minimal spatter, smoke, or debris. This significantly reduces the need for extensive post-weld cleaning, grinding, or polishing, which are often required in traditional welding methods.

- The cleaner welding process saves time and enhances safety by reducing exposure to harmful fumes and particles.

- This is especially beneficial for professionals in environments where cleanliness and aesthetics are crucial, such as in the creation of decorative metalwork or the fabrication of high-precision industrial components.

Where to Find Laser Welding Machine Manufacturer?

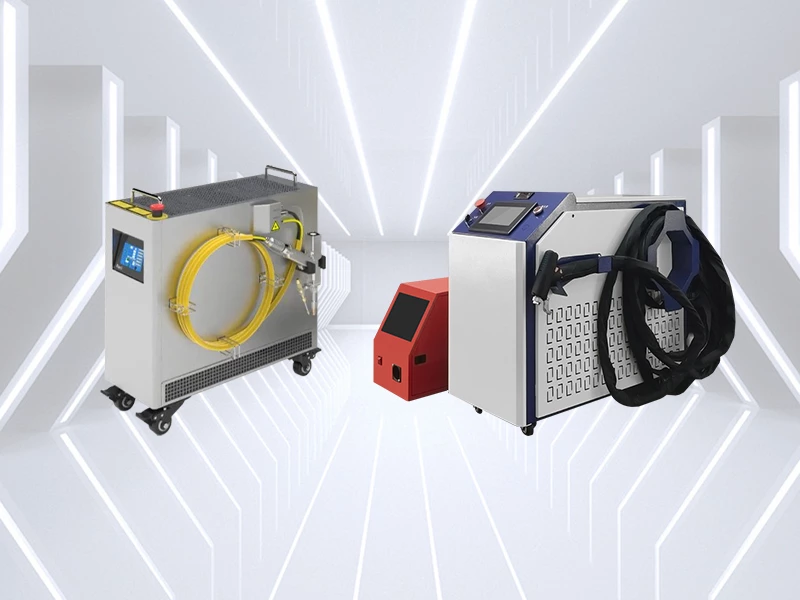

If you are looking to purchase a high-quality handheld metal laser welding machine, choosing a reliable manufacturer is crucial to ensure the performance, durability, and efficiency of the equipment. One such trusted name in the field is Zixu, a leading manufacturer of laser welding machines. Zixu has earned a strong reputation for producing cutting-edge welding technology that meets the needs of both large-scale construction projects and small repair jobs.

Zixu offers a range of metal laser welding machines known for their precision, ease of use, and energy efficiency. Their handheld models are particularly popular for their portability and versatility, making them ideal for complex welding tasks in the construction, automotive, and repair industries.

In addition to metal laser welding, we also offer solutions for metal laser marking, laser cleaning, etc. For more information, please visit our metal application page: metal application.

Recommended Products