How Laser Marking Secures Food Safety in the Packaging Industry

Food packaging is a crucial component in ensuring food quality and safety, and laser marking technology, as an innovative identification method, provides a safe and efficient marking solution for food packaging. This article delves into the working principles, necessity, advantages, and applications of laser marking in the food packaging industry, emphasizing its role in safeguarding food safety.

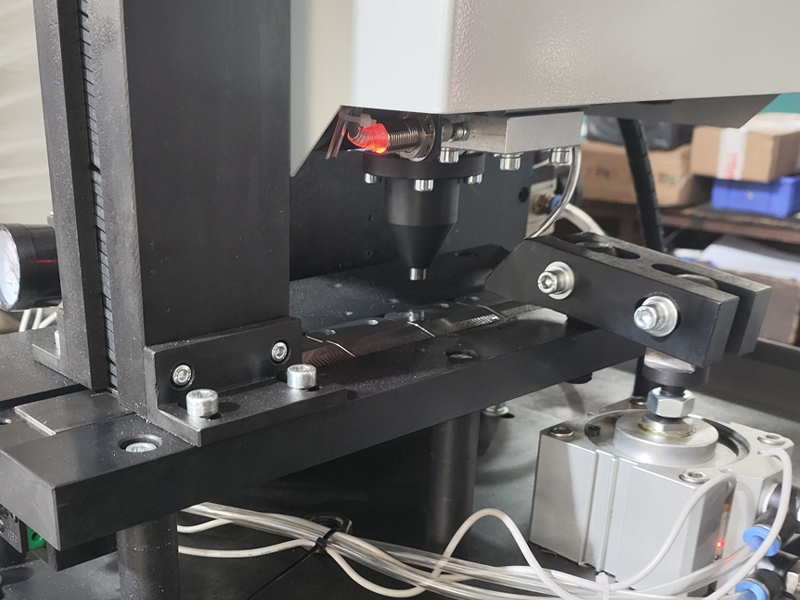

Working Principle of Laser Marking Machines for Food Packaging Marking

Laser marking machines utilize a focused beam of light to create permanent marks on various packaging materials. The process involves directing a high-intensity laser beam onto the surface, which alters the material’s properties through ablation, engraving, or color change.

Different types of lasers, such as CO2, fiber, and UV lasers, are employed based on the packaging material. CO2 lasers are ideal for organic materials like paper and cardboard, while fiber lasers excel on metals and plastics. UV lasers are used for high-precision marking on sensitive materials, including certain plastics and glass.

The laser beam’s interaction with the material creates a durable, high-resolution mark without physical contact, ensuring hygiene and preventing contamination. This non-contact process makes it exceptionally suitable for food packaging, where cleanliness is critical.

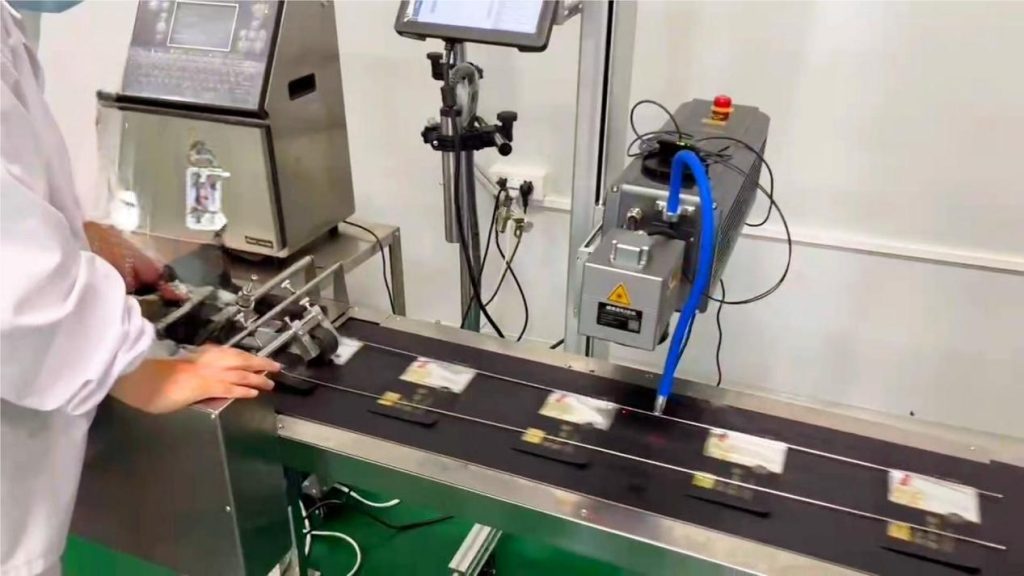

Learn about the marking performance of our laser marking machines across a range of fully automated industrial packaging applications by watching this video.

Why Laser Marking is Necessary on Food Packaging

Firstly, laser marking technology enables precise identification of critical information on food packaging, enhancing food traceability and recognition. Secondly, compared to traditional marking methods, laser marking technology is simple to operate and fast in marking speed, enabling efficient large-scale production. Additionally, it eliminates the need for consumables such as ink, reducing production costs and environmental pollution. This provides food packaging enterprises with a more economical and environmentally friendly marking option.

Importance of Food Packaging Marking

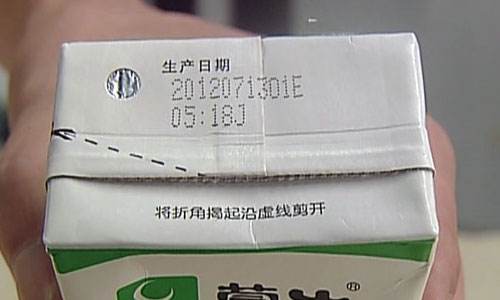

- Traceability: In the event of a product recall or quality control issue, laser-marked codes, such as barcodes, QR codes, and serial numbers, enable precise tracking of products throughout the supply chain. This ensures swift identification and removal of affected items, minimizing risks to consumers.

- Anti-counterfeiting: The unique and permanent nature of laser marks makes them difficult to replicate, providing an effective deterrent against counterfeit products. This protects both consumers and brand integrity. Laser marking can include complex patterns and micro-text, enhancing security.

- Aesthetics: Laser marking offers a clean, precise, and high-quality finish, enhancing the visual appeal of food packaging. This contributes to brand recognition and consumer trust.

Advantages of Laser Marking Compared to Traditional Marking Methods

- Permanence: Laser marks are highly durable and resistant to abrasion, chemicals, and temperature variations. This ensures that essential information remains legible throughout the product’s lifecycle, even in harsh environments. Marks are difficult to erase, providing excellent tamper resistance.

- High Clarity: Laser marking produces sharp, high-contrast marks that are easy to read and scan. This is crucial for accurate data capture and efficient traceability. High resolution ensures that even small text and intricate designs are clearly visible.

- Hygiene and Environmental Protection: As a non-contact process, laser marking eliminates the risk of contamination associated with traditional ink-based methods. This is particularly important in the food industry, where hygiene standards are stringent. Additionally, laser marking does not involve the use of consumables like inks or solvents, reducing waste and environmental impact.

- Wide Adaptability: Laser marking can be applied to a wide range of food packaging materials, including plastics, metals, glass, and paper. This versatility makes it suitable for diverse packaging formats and applications. Notably, the laser engraving machine for plastic is incredibly popular for marking PET bottles, plastic films, and other plastic food containers.

Case Studies – Marking Effects on Different Food Packaging

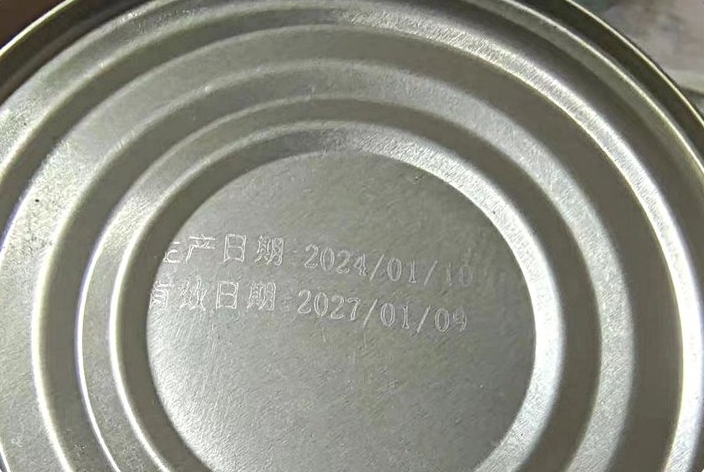

1. Metal Cans: Permanent Marking for Canned Food

Metal cans used for canned food require durable markings that can withstand corrosion and sterilization processes. Laser marking provides a permanent solution, creating high-contrast marks that remain legible even after exposure to harsh conditions. This ensures that vital information, such as production dates and batch numbers, remains intact, supporting traceability and quality control.

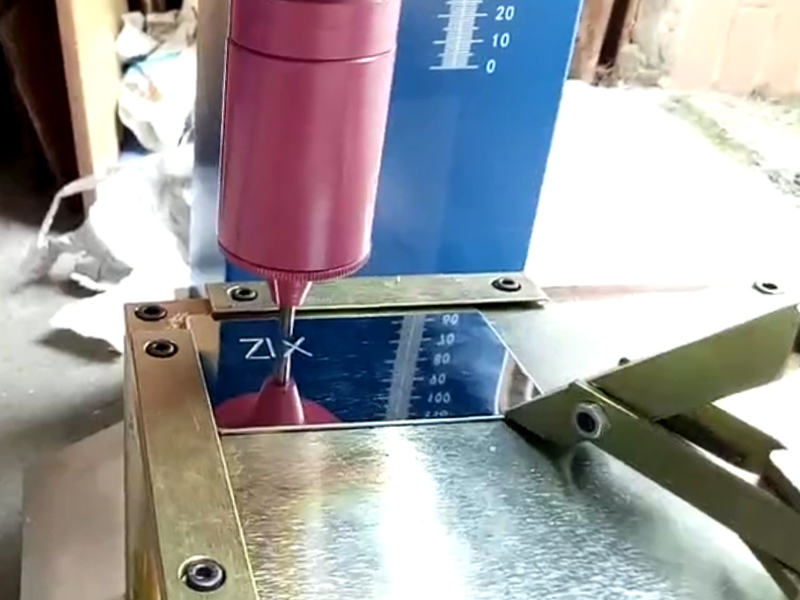

2. Plastic Packaging: Precision Marking on PET Bottle Caps

PET bottle caps require precise and high-resolution markings for product identification and branding. Laser marking, especially using a laser engraving machine for plastic, allows for intricate designs and small text to be accurately marked. The process ensures that the marks are permanent and resistant to abrasion, maintaining the aesthetic appeal and functionality of the packaging.

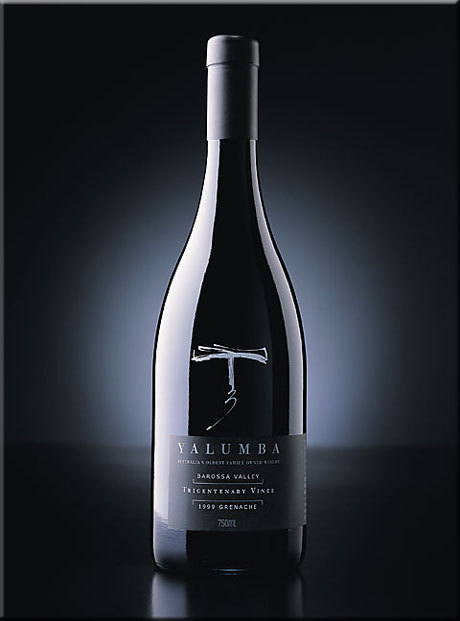

3. Glass Containers: Anti-counterfeiting Traceability for Liquor

Glass containers used for liquor and other beverages benefit from UV laser marking, which creates high-contrast marks without damaging the glass surface. This technology is ideal for anti-counterfeiting measures, as it allows for the marking of unique codes and patterns that are difficult to replicate. Laser marking also supports traceability, enabling the tracking of products throughout the supply chain.

4. Paper Packaging: Marking on Environmentally Friendly Biodegradable Materials

With increasing emphasis on sustainability, paper packaging made from biodegradable materials is gaining popularity. Laser marking offers a clean and efficient method for marking these materials, ensuring that essential information is clearly visible. Low-temperature laser marking techniques are used to prevent damage to delicate materials, maintaining their integrity.

Contact Us for Your Food Packaging Marking Solutions

In summary, the application of laser marking technology in food packaging provides strong support for food safety and production efficiency. It enables precise and clear marking, improving food traceability and identification. Simultaneously, it enhances production efficiency and reduces costs, bringing more competitive advantages to food packaging enterprises. We believe that with the continuous innovation and development of laser marking technology, food packaging will embrace safer and more efficient marking methods.

At Zixu, we provide comprehensive laser marking solutions to meet the specific needs of the food packaging industry. Our expertise and advanced technology ensure your product markings are precise and reliable. Contact us today to learn how we can help you enhance your food packaging marking processes and safeguard food safety.

Recommended Products