How to Choose the Best Nameplate Laser Marking Machine

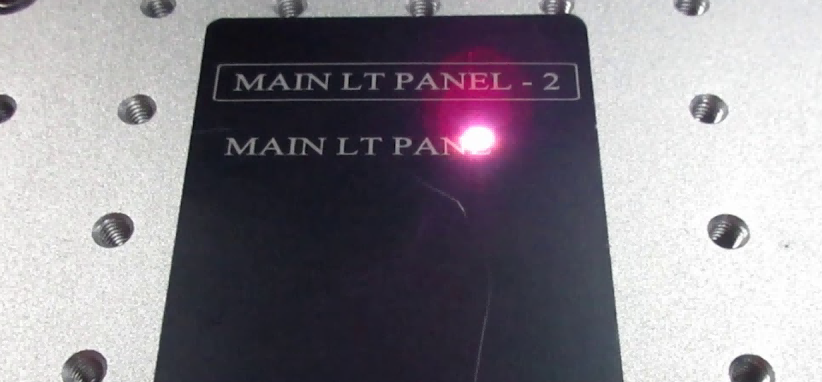

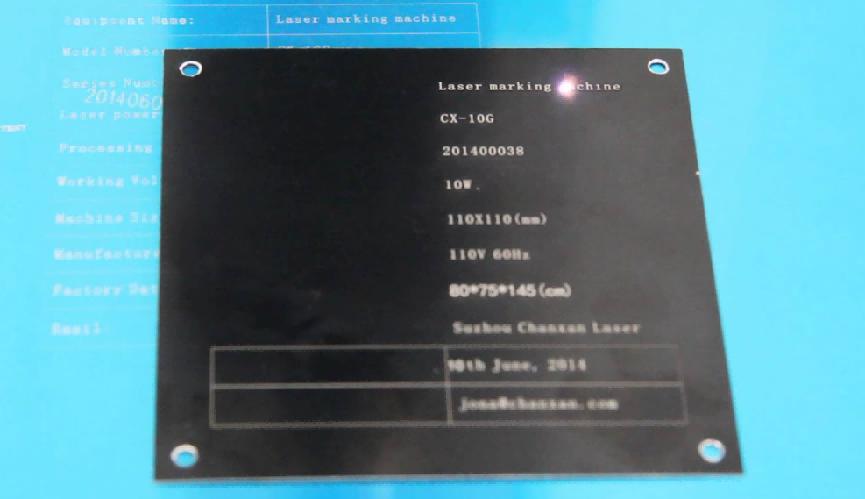

Nameplate laser marking machines have become an essential tool for industries that require precise, durable, and high-quality markings on metal, plastic, or other materials. Whether you’re marking serial numbers, logos, or compliance information, choosing the right laser marking machine is critical to achieving optimal results.

What is Nameplate Laser Marking

Nameplate laser marking is an advanced technology used to create permanent, high-precision markings on nameplates, which are essential for product identification, branding, and regulatory compliance. This process involves using a focused laser beam to alter the surface of materials such as metal, plastic, or glass, resulting in clear, durable, and tamper-proof markings.

Unlike traditional methods like engraving, stamping, or ink printing, laser marking offers several advantages.

Laser marking offers exceptional precision, enabling the creation of intricate designs, fine text, and detailed logos with remarkable accuracy. The durability of these marks is impressive, as they are resistant to wear, corrosion, and environmental elements, ensuring they remain legible over time. This technique is highly versatile, suitable for a wide array of materials, including metals such as stainless steel and aluminum, as well as plastics and ceramics. Additionally, laser marking is an eco-friendly process, being non-contact and free from chemicals, which makes it a cleaner and more sustainable choice.

Nameplate laser marking is widely used in industries such as automotive, aerospace, electronics, and manufacturing, where traceability, quality, and compliance are critical. Whether it’s for serial numbers, barcodes, logos, or safety information, laser marking ensures that nameplates meet the highest standards of performance and reliability.

Types of Nameplate Laser Marking Machines

When choosing a laser marking machine for nameplates, it’s important to understand the different types of lasers available, as each type has unique advantages depending on the materials you plan to mark and the precision required. Below are the most common types of laser marking machines used for nameplate marking:

CO2 laser marking machines

CO2 laser marking machines are highly versatile and widely used for marking non-metallic materials, making them an ideal choice for applications involving plastic, rubber, glass, and ceramics. These lasers work by utilizing a gas mixture to produce an infrared light beam, which is absorbed by various materials, enabling precise and clear engravings. While they may not be as effective on metals as fiber lasers, CO2 lasers excel in creating deep, detailed marks on plastic nameplates and other non-metallic surfaces.

Best suited for: Non-metals such as plastics, wood, glass, and rubber.

Key advantages: Capable of marking a wide range of non-metal materials, and particularly effective for high-quality engravings on plastics.

UV Laser Marking Machines

UV laser marking machines utilize ultraviolet light to produce highly precise markings. The shorter wavelength of the UV laser enables the creation of finer and more detailed marks while generating minimal thermal impact, which makes them perfect for working with sensitive materials that could be damaged by heat. These machines are especially effective for marking plastics, glass, and ceramics, and are commonly used in industries like electronics and medical device manufacturing, where precision and cleanliness are essential.

Ideal for: Sensitive materials like plastics, glass, and ceramics.

Main advantages: Superior resolution, minimal heat damage, and well-suited for intricate designs and small text.

Fiber Laser Marking Machines

Fiber laser marking machines are the most popular choice for marking metal nameplates. They use a solid-state laser with a fiber-optic cable to deliver high-quality marks on materials like stainless steel, aluminum, titanium, and brass. Fiber lasers are highly efficient, offering fast engraving speeds and exceptional precision. They produce high-contrast, permanent marks, making them ideal for industries where durability and legibility are crucial, such as automotive and aerospace.

Best for: Metals, especially stainless steel, aluminum, and titanium.

Key benefits: High speed, low maintenance, high precision, and minimal heat-affected zones.

YAG Laser Marking Machines

YAG (Yttrium Aluminum Garnet) laser marking machines use solid-state technology, employing a crystal to generate the laser beam. Though not as widely used in modern industries as fiber or CO2 lasers, YAG lasers remain effective for marking both metals and plastics. They are especially suitable for deep engravings and are often chosen for applications that require a balance between engraving speed and depth. However, fiber lasers have largely taken over in many sectors due to their superior efficiency and lower maintenance needs.

Ideal for: Marking both metals and plastics, especially for deep engravings.

Main advantages: Versatile, excellent for creating deep markings, though less efficient compared to fiber lasers.

What to Consider When Choosing a Nameplate Laser Marking Machine

When selecting a nameplate laser marking machine, there are several key factors that should guide your decision. Below is a helpful breakdown of these factors:

| Factor | Considerations |

| Material Compatibility | – Choose a machine compatible with the materials you plan to mark (metal, plastic, etc.). |

| – Fiber lasers: Best for metals (steel, aluminum, brass). | |

| – CO2 lasers: Ideal for plastics and some coated metals. | |

| – UV lasers: Great for delicate materials (plastics, ceramics). | |

| Marking Speed & Efficiency | – Faster speeds lead to higher throughput. |

| – Consider the balance between speed and marking quality (too fast can affect detail). | |

| Laser Power | – Higher power (50W-100W) for thick metals and deep engravings. |

| – Lower power (20W-30W) for fine detail and light markings on thinner materials. | |

| Precision & Resolution | – Choose machines with high precision (low micron level) for detailed designs. |

| – Important for small or intricate nameplates (e.g., logos, serial numbers). | |

| Ease of Use & Software Integration | – Look for user-friendly interfaces and software integration with your design tools. |

| – Features like auto-scaling and variable text fonts enhance versatility. | |

| Maintenance & Durability | – Opt for machines that require minimal maintenance and offer reliable performance. |

| – Ensure availability of replacement parts and service support. | |

| Budget | – Determine your budget, considering both initial costs and long-term maintenance/consumable costs. |

| – Balance performance with cost efficiency. |

This structure allows the key factors to be quickly referenced, making it easier to compare and prioritize based on specific needs.

Tips for Testing and Evaluating Machines

Before committing to a nameplate laser marking machine, it’s essential to thoroughly test and evaluate its performance to ensure it aligns with your needs. Here are some practical tips to guide you through the process:

1. Inspect Marking Quality: Assess the quality of the markings by thoroughly inspecting the sample for clarity, contrast, and precision. Pay close attention to details such as sharp edges, uniform depth, and high resolution, particularly if your nameplates feature complex designs or small text.

2. Test the Software and User Interface: Evaluate the machine’s software and user interface to ensure it is intuitive and easy to navigate. Check for important features such as design customization options, barcode generation, and compatibility with common file formats like DXF, BMP, or AI. A well-designed software interface can greatly enhance the efficiency of your workflow.

3. Assess Speed and Efficiency: Time the marking process to determine how quickly the machine can complete tasks. If you have high-volume production needs, speed is a critical factor to consider.

4. Evaluate Build Quality and Stability: Inspect the machine’s construction and overall build quality. A sturdy, well-designed machine is more likely to deliver consistent performance and have a longer lifespan.

5. Consider After-Sales Support: When selecting a nameplate laser marking machine, it’s important to assess the supplier’s after-sales support, including customer service, technical assistance, and warranty terms. A strong after-sales support system can be invaluable if any issues arise in the future.

By considering these factors, you can make an informed choice and select a machine that offers the performance, reliability, and quality that aligns with your business needs. Taking the time to thoroughly test and evaluate your options will help ensure that your investment meets both your immediate and long-term requirements.

Choosing the right type of laser marking machine for nameplates depends largely on the materials you’re working with and the specifics of the marking you need. Fiber lasers are typically the go-to option for metal nameplates due to their efficiency and precision, while CO2 lasers excel in marking non-metal materials like plastics. UV lasers offer the highest precision for delicate materials, and YAG lasers are best for deep, detailed marks on both metals and plastics. By understanding the strengths of each laser type, you can choose the most suitable machine for your application.

If you have any needs for marking nameplates or having any questions, please contact our teams fo more information!

Recommended Products