How to Choose the Right Chassis Number Marking Machine for Your Needs

Choosing the right chassis number marking machine is crucial when it comes to ensuring vehicle identification and regulatory compliance. There are a variety of options on the market, and the right choice depends on your specific requirements, such as material type, production scale, and budget. Below, we’ll explore the importance of chassis number marking, the types of marking machines available, key factors to consider, and some popular brands to help you make an informed decision.

Why is Chassis Number Marking Important?

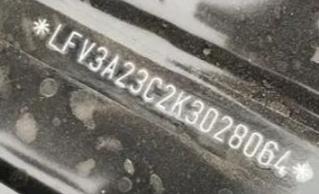

Chassis number marking, commonly referred to as Vehicle Identification Number (VIN) marking, is essential for vehicle identification and traceability. This unique identifier plays a vital role in ensuring compliance with industry regulations, preventing vehicle theft, and aiding in the recovery of stolen vehicles. For manufacturers, precise and durable chassis number markings are required by law to ensure that vehicles can be tracked throughout their entire lifecycle, from production to end-of-life.

Proper chassis number marking ensures that every vehicle is distinguishable and traceable in a global supply chain. In industries like automotive manufacturing, where regulatory inspections are stringent, non-compliance with VIN marking standards can lead to significant fines or recalls.

Additionally, poor-quality or easily removable markings can compromise a vehicle’s identity, making it more vulnerable to tampering or fraud. This is why choosing a reliable and durable chassis number marking machine is crucial—not only for legal compliance but also to protect the integrity of your vehicles and brand.

Types of Chassis Number Marking Machines for You

When choosing a chassis number marking machine, it’s crucial to understand the different technologies available and how each one can fit specific use cases. Each type of machine operates using a unique method, offering distinct advantages in terms of precision, durability, speed, and cost. Below, we break down the primary types of chassis number marking machines to help you determine which one is the best match for your requirements.

Laser Marking Machines

Laser marking machines are widely regarded for their precision and versatility. Using a concentrated beam of light, these machines can engrave or etch detailed markings onto various materials without physically touching the surface. This non-contact method ensures that the integrity of the material is preserved, making laser marking ideal for delicate or highly finished surfaces, such as polished metals.

Laser marking is known for its high speed and accuracy, making it the preferred choice in industries that require fast production cycles and high-quality results. It can produce permanent, tamper-resistant markings that are both aesthetically pleasing and highly durable, withstanding harsh conditions such as extreme temperatures or chemical exposure. These machines are typically used in high-volume manufacturing environments where consistency, precision, and compliance are critical.

- Best For: Automotive manufacturers requiring fast, high-quality, and precise markings.

- Advantages: Non-contact process, high resolution, durable marks, low maintenance, and suitable for various materials like metals, plastics, and composites.

- Disadvantages: Higher upfront cost compared to other marking technologies, may not achieve deep engravings as dot peen machines can.

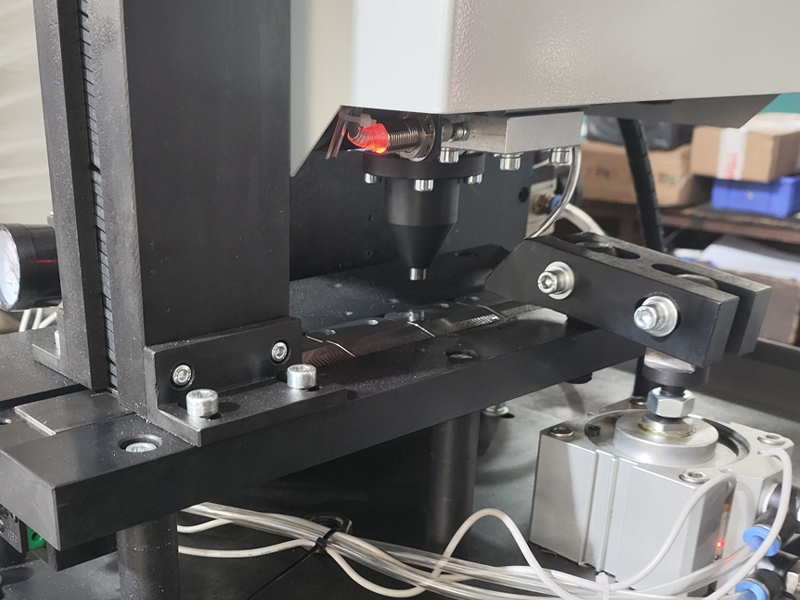

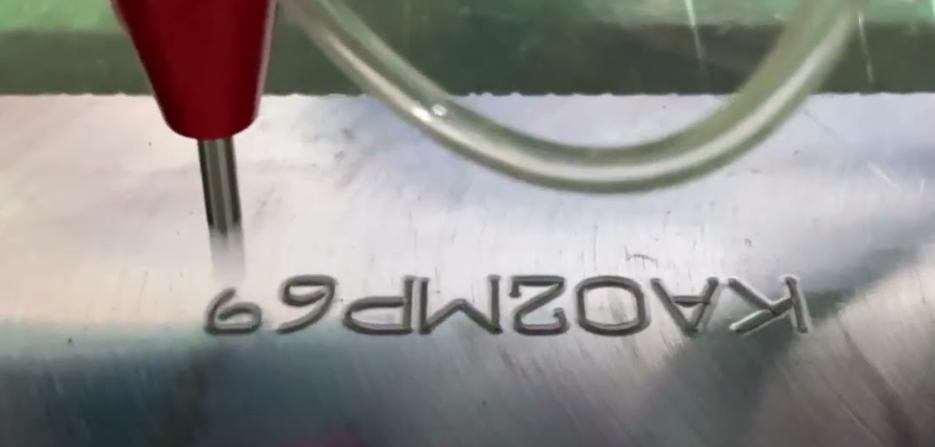

Dot Peen Marking Machines

Dot peen marking machines use a pin or stylus that strikes the surface to create a series of small, closely spaced dots that form the chassis number or VIN. This impact-based method is robust, making it ideal for deep, durable marks that are difficult to erase or tamper with. Dot peen marking is commonly used in industries where the environment is harsh, such as in automotive, heavy machinery, and metal fabrication.

Best For: Heavy-duty applications where durability and depth of the markings are more important than aesthetics.

Advantages:

- Deep, Permanent Marks: Dot peen machines can create deep indentations in the surface of materials, which are not only difficult to remove but also highly resistant to wear, corrosion, and tampering.

- Versatile Material Compatibility: Dot peen marking can be used on a wide range of materials, including hard metals like steel and softer ones like plastic, making it adaptable to different industries.

- Cost-Effective: Dot peen machines are generally more affordable compared to laser systems, making them a popular choice for small to medium-sized businesses.

- Durability in Harsh Environments: The markings created by dot peen machines are particularly suited for environments exposed to extreme conditions, such as heat, chemicals, and mechanical wear.

While dot peen machines are highly effective for heavy-duty marking, the markings they produce may not have the fine, aesthetic quality achieved by laser marking. Additionally, the dot peen process can be noisy due to the impact mechanism.

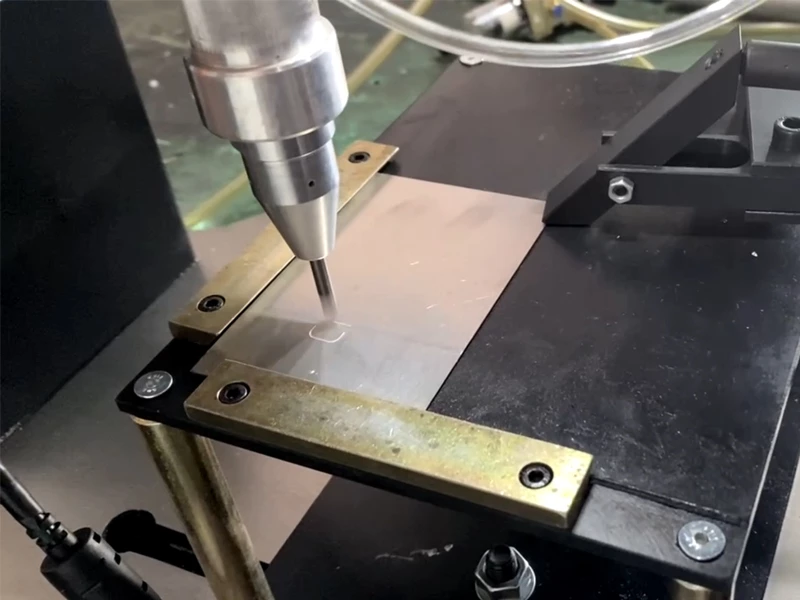

Scribing Marking Machines

Scribing marking machines, also known as “scratch marking” machines, use a diamond-tipped stylus or carbide needle to drag across the surface of a material, creating continuous, engraved lines. This process is quieter than dot peen marking and results in clean, precise markings with minimal surface deformation, making it suitable for environments where noise control is important.

Ideal Applications: Industries that need deep, silent marking with high-quality, continuous lines, especially on softer materials like aluminum or composite surfaces.

Advantages:

- Quiet Operation: Unlike the hammering action of dot peen, scribing offers a quieter alternative, perfect for noise-sensitive work environments.

- High-Quality Markings: Produces smooth, continuous marks that are highly readable and professional-looking, particularly on flat or smooth surfaces.

- Minimal Surface Damage: The drag-based scribing process reduces the risk of material damage or distortion compared to impact methods.

- Great for Large Parts: Commonly used to mark larger parts, such as vehicle frames and chassis, where clear, continuous markings are important.

However, scribing may not be the best option for harder materials like steel, where deeper marks are required. In such cases, dot peen or laser marking machines may be more suitable.

Each machine type, like dot peen marking, laser marking, and scribe marking machines, has its strengths. Selecting the appropriate one will contribute to achieving high-quality markings that meet industry standards and enhance vehicle traceability.

Things to Consider When Choose a Chassis Number Marking Machine

To make an informed decision when purchasing a chassis number marking machine, focus on the following crucial factors, which will directly influence the machine’s performance and suitability for your business.

Type of Material and Marking Requirements

The type of material you are marking is one of the most crucial factors when choosing a chassis number marking machine. Different marking technologies are better suited to specific materials, and selecting the wrong machine could lead to poor quality or even unreadable markings.

- Metals: Materials like steel or aluminum are common in chassis manufacturing. Laser marking machines excel in creating clean, precise markings on these metals without causing damage to the surface. For deeper marks on harder metals, dot peen marking machines are ideal as they provide a strong impact that can penetrate tough surfaces.

- Plastics or Coated Materials: If your chassis or parts include plastic or coated surfaces, laser marking is also a great option, as it can mark without stripping coatings or damaging the material. For less delicate plastics, dot peen machines can work but may result in rougher marks.

Considerations: Always ensure that the marking machine is capable of handling the type of material without compromising the marking quality or causing unnecessary wear on the machine itself.

Marking Depth and Durability Requirements

Marking depth and durability are crucial for ensuring that chassis numbers remain visible and tamper-resistant throughout a vehicle’s lifespan. Depending on your industry and regulatory requirements, you may need either shallow surface markings or deeper engravings to withstand wear and environmental conditions.

- Shallow Markings: For applications where aesthetics are a priority, such as luxury vehicles, laser marking provides fine, shallow engravings that are visually appealing. These markings are ideal for branding or situations where permanence is required but not necessarily depth

- Deep Markings: In industries where tamper resistance and long-term durability are essential, like automotive manufacturing, dot peen machines are the preferred choice. They produce deep engravings that are highly resistant to physical wear, abrasion, and environmental factors such as heat and moisture, making them difficult to alter or remove.

Industry Regulations: It’s important to consider regulatory standards that dictate the required depth or permanence of chassis number markings, particularly in sectors like automotive, aerospace, or defense. Failing to comply can lead to fines, product recalls, or legal issues.

Mobility: Portable vs. Fixed Machines

Another critical factor to consider is whether you need a portable or fixed marking solution. This decision depends on the nature of the items being marked and the flexibility required within your operations.

- Portable Marking Machines: If you work in an environment where chassis numbers need to be marked on large, immovable objects like trucks, trailers, or heavy machinery, a portable marking machine is a must. These machines offer flexibility and mobility, allowing you to bring the marking process directly to the vehicle or part. Portable options are particularly useful in field operations or outdoor settings.

- Fixed Marking Machines: For factory settings, where precision and repeatability are critical, a fixed marking machine is a better choice. These machines are typically installed at a dedicated station within the production line and offer greater stability, accuracy, and speed. They can be integrated with automated systems to streamline production.

If your business operates in multiple environments, such as both factory and fieldwork, you may need both portable and fixed marking machines to cover all your needs.

Production Volume and Speed

Your production volume plays a significant role in determining the right marking machine for your needs. Selecting a machine that matches your production speed will help you maintain efficiency while ensuring high-quality markings.

- High-Volume Production: For large-scale operations requiring fast production, laser marking machines are often the best option. They can quickly mark multiple units with precision, ensuring consistent quality across a high volume of products.

- Lower-Volume or Custom Production: In smaller-scale manufacturing or custom vehicle production, dot peen or scribing machines may be more cost-effective. While these machines operate at a slower pace, they offer highly durable markings, making them ideal for situations where longevity is more important than speed.

- Automation Needs: For automated assembly lines, consider CNC-based systems that integrate seamlessly into your production workflow. These machines enable continuous, hands-free operation, which is crucial for maintaining high throughput in automated environments.

By carefully evaluating these factors, you can make a well-informed decision. The right marking machine will not only meet your immediate needs but will also scale with your business as it grows.

Popular Chassis Number Marking Machine Brands

In addition to the above factors, it is also important to choose a reliable and reputable brand. The following are some of the most trusted brands in the industry. Their chassis number marking machines provide a range of solutions for various applications.

1. SIC Marking

SIC Marking offers a wide range of laser, dot peen, and scribing machines. Known for durability and precision, they are ideal for industries like automotive and aerospace, providing both portable and fixed marking solutions.

Key Products: Laser and dot peen systems, automated marking solutions.

2. Gravotech

Gravotech specializes in laser and dot peen marking, offering highly precise and aesthetic engravings. They are favored in sectors like automotive and electronics for their clean, permanent marks.

Key Products: CO2 and fiber laser systems, dot peen machines.

3. Telesis

Telesis is known for fast, accurate marking systems suitable for high-volume production. Their laser and dot peen machines are widely used in automotive and medical device industries.

Key Products: Fiber laser and dot peen machines.

5. Zixu

Zixu, a Chinese brand, offers cost-effective and versatile marking solutions, specializing in laser and dot peen systems. Their machines are highly suitable for automotive applications.

Key Products: Fiber laser markers, dot peen marking machines, and scribe marking machines for chassis number marking.

4. Markator

Markator focuses on portable dot peen and scribing machines designed for heavy-duty applications. Their rugged marking solutions are perfect for industries like construction and transportation.

Key Products: Portable dot peen systems, scribing machines.

Choosing the right chassis number marking machine depends on a variety of factors, including the type of material, required marking depth, production volume, and mobility needs. Whether you need the precision of a laser, the durability of a dot peen, or the flexibility of a portable machine, the right marking solution will ensure compliance, security, and long-term reliability in vehicle identification.

For more information about chassis number marking machines, you can consult our service team.

Recommended Products