How to Choose the Right Laser Marking Machine for Leather Fabrics?

Leather and fabric, renowned for their unique texture and durability, are staples in industries such as apparel, footwear, and luggage. Laser marking, celebrated for its efficiency and precision, has become an indispensable tool for marking these materials. However, with a plethora of laser marking machines on the market, selecting the optimal machine for leather and fabric applications can be challenging.

This article will provide a comprehensive guide to choosing the right laser marking machine based on the specific characteristics of leather and fabric.

1. The Principle of Laser Processing Leather

Laser marking on leather involves the application of a laser beam to the leather surface, triggering chemical reactions such as oxidation, carbonization, and vaporization. These reactions result in the formation of the desired patterns or text. By adjusting the laser type and parameters, various effects can be achieved:

- Ablation: A thin layer of material is removed by the laser beam, resulting in a permanent mark or engraving.

- Coloration: The laser can induce localized chemical changes in the leather, altering its color.

- Marking: Intricate patterns, logos, and text can be created on the leather surface using the laser.

2. Advantages of Laser Processing Leather

Laser marking offers significant advantages over traditional methods when it comes to leather. Employing digital control technology, laser printing on leather can achieve exceptional speed, precision, clarity, repeatability, and stability. Key benefits include:

- High Precision: The precision of leather laser printing can reach 0.01mm, which can achieve fine printing on leather products, ensuring the clarity and stability of patterns and letters.

- Non-contact Process: Eliminates physical contact with the material, minimizing damage and ensuring consistent results.

- High Efficiency And Energy Saving: Leather laser printing does not require templates and ink, and the printing speed is fast, which not only saves manpower, time and cost, but also has the advantages of being environmentally friendly and energy-saving.

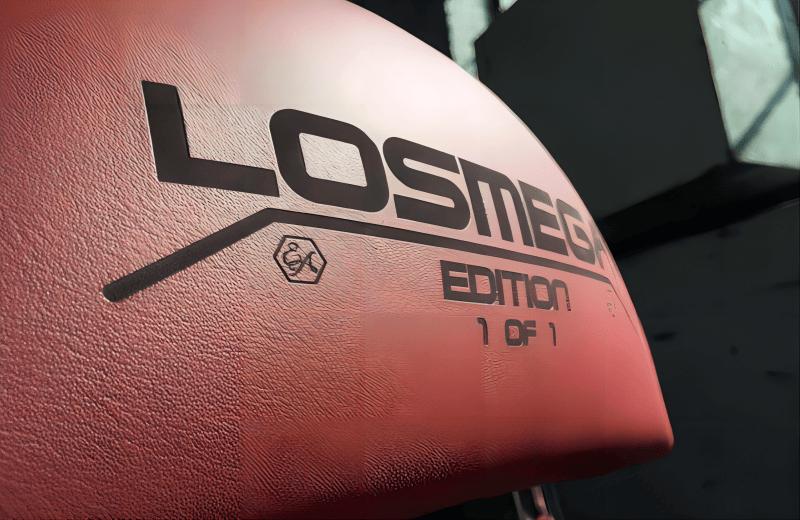

- Personalized Customization: Leather laser printing can directly print personalized customized content such as patterns, letters and numbers on leather products, meeting consumers’ demand for personalization and customization.

- Wide Range of Applications: It can be marked on various colors and types of leather, including artificial leather, PU leather, PVC leather, etc.

3. How to Choose the Right Laser Marking Machine for Leather Fabrics?

Selecting the appropriate laser marking machine requires careful consideration of your specific needs and the characteristics of your leather fabrics.

3.1 Clarify Product Requirements

Material Identification: Determine the specific type of leather or fabric to be marked, considering factors such as thickness, color, and composition (e.g., full-grain, split leather, suede).

Marking Requirements: Clearly define the desired markings, including logos, patterns, barcodes, or personalized text.

Production Efficiency Assessment: Evaluate the required marking depth and intensity, and estimate the production volume to determine the necessary processing speed.

Budget Allocation: Set a practical budget for the laser marking machine and associated costs.

3.2 Choose the Right Laser Type

CO2 and UV laser marking machines are the two primary types of lasers used for leather processing. While both offer precise marking capabilities, they exhibit distinct characteristics in terms of material compatibility and marking outcomes. Key differences between these two laser types are outlined below:

| Feature | CO2 Laser Marking Machine | UV Laser Marking Machine |

| Suitable Materials | Non-metallic materials, including leather | Sensitive materials, coated or treated leathers |

| Marking Quality | Clear, durable markings | High precision, intricate designs |

| Power Output | High | Lower |

| Cost | Relatively cost-effective | Generally more expensive |

| Heat Affected Zone | Larger | Smaller |

CO2 Laser Marking Machine

- Applications: Ideal for marking a wide range of non-metallic materials, including natural and synthetic leathers. Offers both high-precision and high-speed marking capabilities.

- Benefits: Provides clear and durable markings on leather due to excellent material absorption. Offers high power output and cost-effectiveness.

- Considerations: May not be suitable for extremely delicate or light-colored leather materials.

UV Laser Marking Machine

- Applications: Best suited for marking sensitive materials, such as coated or treated leathers. Ideal for intricate designs and color marking.

- Benefits: Minimal heat-affected zone, ensuring precision and detail in marking.

- Considerations: Lower power output compared to CO2 lasers, resulting in potentially slower processing speeds. Typically higher in cost.

4. Application Areas for Laser Marking on Leather

Leather laser marking machines have become indispensable tools in the fashion industry due to their high precision, efficiency, and non-polluting nature. Leather laser marking has a wide range of applications:

Application Areas for Laser Marking on Leather

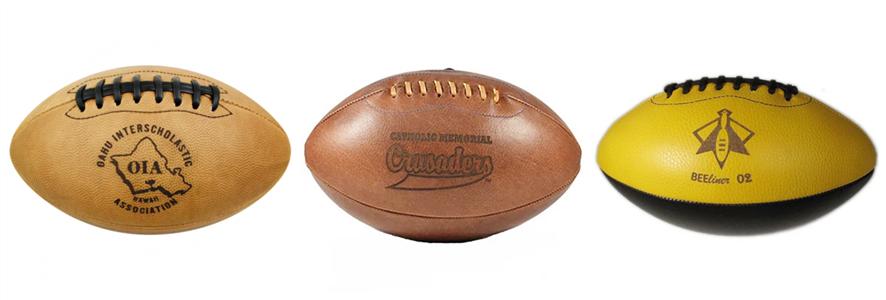

Leather Goods Industry: Laser marking can be used for the identification and decoration of leather products such as bags, wallets, shoes, clothing, and sofas. By laser engraving exquisite patterns, trademarks, dates, logos, or text onto the leather surface, the added value and market competitiveness of products can be enhanced.

Apparel Industry: Laser marking technology can be used for the production of clothing labels, ensuring the durability and aesthetics of labels while avoiding damage to the fabric.

Luggage and Handbag Industry: Laser marking can be used to create various patterns and logos on luggage and handbags, enhancing the uniqueness and brand value of the products.

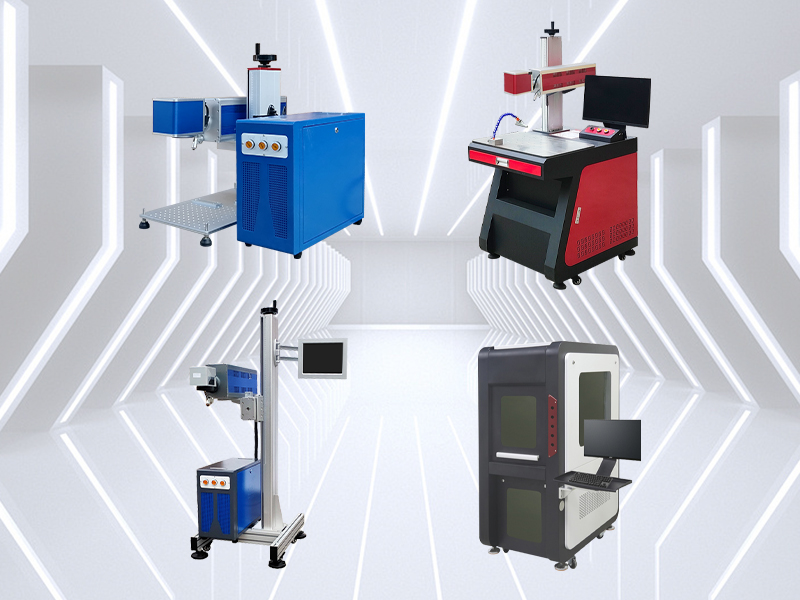

5. Try Zixu’s Leather Laser Machines

Zixu is a leading manufacturer of high-quality laser marking machines, offering a wide range of solutions tailored to the leather and textile industry. Their innovative leather laser machines are designed to:

- Enhance Productivity: Increase production speed and efficiency while minimizing downtime.

- Improve Quality: Deliver consistent and high-quality markings with exceptional precision.

- Reduce Costs: Optimize operational costs through energy efficiency and reduced maintenance.

- Meet Diverse Needs: Offer a range of models to suit various applications and budgets.

By carefully considering your specific requirements and exploring the options available from reputable manufacturers like Zixu, you can select the ideal laser marking machine to enhance your leather fabric production process and achieve superior results.

Recommended Products