How to Choose the Right Metal Tag Engraving Machine?

Metal tags are versatile and durable, used primarily for identification, branding, and tracking. Choosing the right metal tag engraving machine is important to ensure high-quality metal tag marking. This guide will walk you through everything you need to know about metal tags, their applications, and how to choose the best engraving machine for your needs. Let’s read on.

What are Metal Tags?

First of all, you need to know what are metal tags, and how they are use in industries.

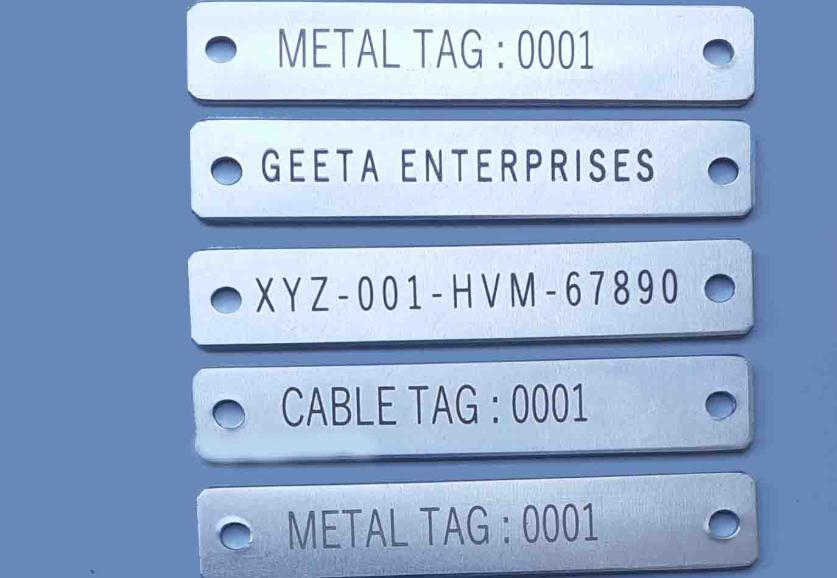

Generally, metal tags are small, flat pieces of metal, typically made from materials like stainless steel, aluminum, brass, or copper. Because they are durable, resistant to wear and tear, and able to withstand harsh environments, they are often used for marking, identification, and branding. Metal tags can be engraved, stamped, or etched with text, logos, barcodes, or serial numbers.

Application of Metal Tags

Metal tags have a wide range of applications across various industries due to their durability, customization options, and versatility. Here are the several most common industries and their uses of metal tags:

- Metal tags are used in the manufacturing and industrial sectors to identify assets, label equipment, and control inventory. They are sturdy and wear-resistant, making them excellent for use in tough conditions.

- Aerospace and aviation use metal tags to identify parts, serial numbers, and ensure regulatory compliance. They are resistant to harsh temperatures, vibration, and chemical exposure.

- Metal tags are used in the automobile industry for vehicle identification (VIN tags), part tracking, and providing essential information concerning safety requirements, manufacturing, and quality control.

- Metal tags are used in hospitals to identify equipment, track medical devices, and ensure regulatory compliance. They’re also utilized in medical implants to ensure patient safety and tracking.

- Metal tags are utilized for inventory management, barcoding, and tracking products throughout the supply chain. Their resilience ensures they remain intact through shipping and storage.

What is Metal Tag Engraving

Metal tag engraving is a specialized process that involves carving or etching designs, text, or codes onto the surface of a metal tag. This technique is widely used to create durable, permanent markings that can withstand harsh environments and heavy use. The process is highly precise, ensuring that the final product is both functional and visually appealing.

There are several methods of metal tag engraving, each with its own unique advantages. Among the many methods, laser engraving and dot pin marking are the two most worthy of our attention.

Laser Engraving Machine

Laser engraving is one of the most popular techniques, using a focused laser beam to remove material from the metal surface. This method is known for its precision, speed, and ability to create intricate designs, making it ideal for detailed work like logos or fine text.

Laser engraving machines can engrave on a wide variety of metals, including stainless steel, aluminum, and brass, and they are particularly useful when high levels of detail and customization are required. The laser’s high intensity allows it to leave permanent, clean marks without causing distortion or damaging the surrounding area. Laser engraving is perfect for industries requiring high-resolution engraving, such as aerospace, automotive, and medical sectors.

Dot Peen Marking Machine

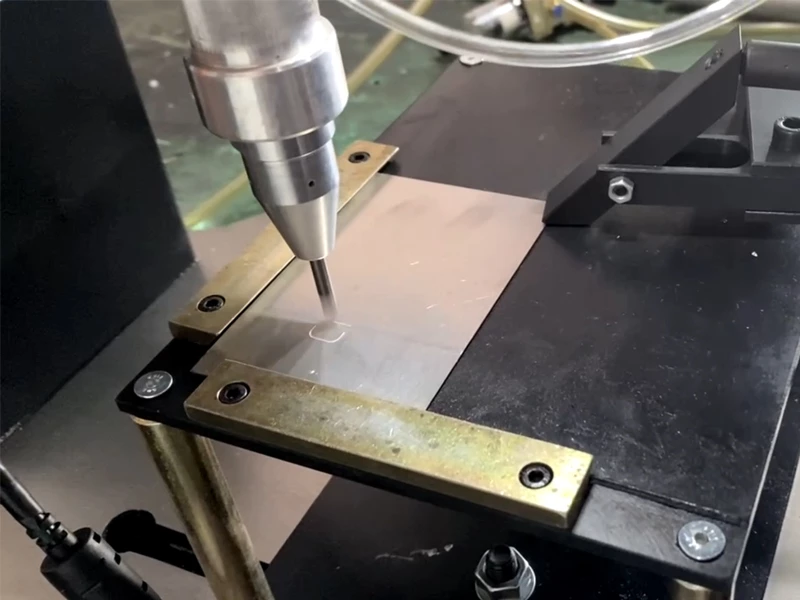

Dot peen marking is another option, utilizing a stylus to create a series of dots that form text or patterns. This method is often used for simple, functional markings like serial numbers or barcodes.

Dot peen marking machines are often used on materials that are tougher or more resistant to lasers, such as hardened steel. This method ensures that the markings are both durable and highly legible, even in environments that involve frequent abrasion or exposure to harsh chemicals. It is commonly found in industries like manufacturing, construction, and logistics, where identification of tools, equipment, and parts is essential for operational efficiency.

How to Choose a Metal Tag Engraving Machine

When selecting a metal tag engraving machine, it’s important to consider various factors to ensure the equipment meets your specific needs. Here’s a guide to help you make an informed decision:

Clear Your Needs

Before choosing an engraving machine, it’s important to clearly define the objectives and scope of your engraving tasks. Consider the following factors:

- Tag Size and Material: Identify the size of the metal tags you intend to engrave and the type of metal (such as stainless steel, aluminum, or brass). Certain machines may be better suited for engraving smaller tags or specific metals, while others are designed for larger projects or more difficult materials.

- Work Volume: Are you working with small batches or large quantities of tags? If you need to engrave at a high volume, selecting a machine that prioritizes speed and efficiency could be crucial.

- Detailing Requirements: Some projects require intricate designs, fine text, or logos. If precision is key for your tasks, you might need a machine capable of detailed engraving. However, for simpler tasks like serial numbers or barcodes, a more basic system might be adequate.

Choose the Right Engraving Technology

The selection of engraving technology largely depends on your specific needs regarding detail, speed, and material compatibility. Two of the most widely used methods are:

Laser Engraving is perfect for achieving fine details, logos, and complex patterns. It employs a concentrated laser beam to etch or cut into the metal, offering high precision, speed, and versatility in working with different metals. Laser engravers are particularly suited for industries that require intricate work, such as aerospace, jewelry, and medical devices.

Dot Peen Marking, In contrast, dot peen marking involves a stylus that creates a series of dots to form text or patterns. This method is ideal for simpler, functional engravings, such as serial numbers, barcodes, or part numbers. Known for its durability, dot peen marking is particularly effective on tougher materials, making it a popular choice for industrial and manufacturing environments.

Your decision between laser engraving and dot peen marking will depend on the complexity of your design and the type of material you intend to engrave.

Consider Machine Features

Speed: Faster machines are essential for high-volume production.

Software Compatibility: Look for machines that work with popular design software for easy customization.

Ease of Use: User-friendly interfaces and automated features can save time and reduce errors.

Durability: Choose a machine built with high-quality materials for long-term use.

By carefully considering your needs, the type of engraving technology, and key machine features, you’ll be able to select the best metal tag engraving machine for your business. Whether you’re engraving for branding, asset identification, or regulatory compliance, the right machine will ensure precision and efficiency in producing high-quality, durable metal tags.

Need a Metal Tag Engraving Machine?

If you’re in the market for a metal tag engraving machine, it’s essential to choose a reliable manufacturer that offers high-quality, durable, and efficient equipment. One such trusted name in the industry is Zixu, a leading manufacturer of metal tag engraving machines known for their precision, innovation, and customer-centric approach.

By choosing Zixu, you’re not just investing in a machine—you’re investing in a partnership with a manufacturer that prioritizes quality, reliability, and customer satisfaction. Whether you need a machine for industrial asset management, personalized jewelry, or promotional products, Zixu has the perfect solution for you. For more information, please visit our official website.

Recommended Products