Innovative Application of Laser Marking Machines in Fruit Marking

In the modern food industry, labels and markings serve not only as essential tools for product identification but also as crucial elements for brand promotion and anti-counterfeiting. However, traditional paper labels often suffer from drawbacks such as easy detachment, susceptibility to tampering, and environmental pollution. With advancements in technology, laser marking machines, offering non-contact, high-precision, and environmentally friendly marking, have gradually found their application in fruit marking, revolutionizing the fruit industry.

This article delves into the fundamental principles of laser marking, its advantages in fruit marking, a case study, and recommendations for suitable laser marking machines.

Basic Principle of Laser Marking Machines

A laser marking machine generates a high-intensity laser beam from a laser source. This beam is then manipulated through an optical system, including mirrors and lenses, to focus the beam onto the surface of the material to be marked.

When the laser beam strikes the material’s surface, the material absorbs a portion of the laser energy, causing the surface temperature to rise and resulting in a phase change or ablation, forming a permanent mark. This mark can be text, graphics, barcodes, or other patterns and is characterized by its durability, clarity, and resistance to fading.

Advantages of Laser Marking on Fruits

In recent years, laser marking technology has found increasing applications in the fruit industry. To highlight their brands, many imported or locally branded fruits have labels affixed to their surfaces indicating the brand, origin, and other information. However, these labels are easily damaged or counterfeited. Laser marking technology can directly mark the fruit peel without damaging the fruit flesh, providing an effective anti-counterfeiting measure that is both unique and innovative.

Environmental Friendliness and Pollution-Free

Unlike traditional marking methods that rely on inks or chemicals, laser marking is a clean process that minimizes environmental impact. It eliminates the need for paper labels, ink, and adhesives, reducing waste and energy consumption during production. Laser marking is an eco-friendly process that minimizes its ecological footprint.

High Precision and Clarity

Laser marking machines can produce highly precise and detailed marks, enabling clear and legible codes, logos, or other information to be etched onto fruit surfaces.

Effective Anti-counterfeiting

Laser-marked codes are difficult to counterfeit, effectively preventing unauthorized alterations of production dates, batch numbers, and other information, ensuring food safety.

Enhanced Brand Image

Laser marking allows for direct printing of brand logos, dates, and other information onto fruits, enhancing product brand value and market competitiveness. It adds a touch of sophistication and professionalism to the product, elevating its perceived value.

No Impact on Fruit Quality

The non-contact nature of laser marking ensures that the fruit’s surface is not damaged and that its quality, taste, or shelf life remains unaffected.

Case Study: Marking Traceability Codes on Avocados

Marks & Spencer (M&S) has introduced a new laser marking method for avocados to reduce paper waste. By switching from paper adhesive labels to laser marking, the retailer can save 10 tonnes of labels and backing paper, as well as 5 tonnes of adhesive each year.

Once harvested at their origin and graded according to their source, avocados are shipped to the UK. Upon arrival, ripe avocados are placed on trays and conveyed through a laser marking machine.

The laser will imprint the retailer’s logo, best before date, country of origin, and a checkout code onto the avocado’s outer skin. M&S claims that while the intense light may cause the outermost layer of the fruit’s skin to fade slightly, it does not damage the fruit and can be performed with great precision.

A fruit technology expert stated, “Given the success of this practice on avocados, we can extend this laser labeling technology to a wide variety of other fruits and vegetables. This presents an exciting opportunity to reduce product packaging waste exponentially.”

Laser marking machines have already been successfully applied to mark various fruits such as citrus, watermelon, and avocados. These fruits often have a waxy layer on their surface, which the laser beam can penetrate to interact with pigments in the fruit skin, causing discoloration and evaporating moisture to create the mark.

Additionally, laser marking machines can print PLU codes, QR codes, and barcodes onto the fruit’s surface, facilitating consumer identification and traceability.

CO2 Laser Marking Machine for Fruit

A CO2 laser marking machine focuses a high-energy laser beam onto the surface of a fruit, causing the surface material to vaporize or discolor, thus creating a permanent mark. Due to the highly concentrated energy of the laser beam, it does not damage the interior of the fruit, ensuring its freshness and quality.

Compared to traditional labels, CO2 laser marking offers several significant advantages:

- High Precision and Clarity: CO2 laser marking machines can produce fine, clear marks on fruit surfaces, such as brand logos, production dates, batch numbers, and barcodes, ensuring accurate and reliable information and enhancing product quality.

- Environmental Friendliness: Unlike traditional labels that require ink and adhesives, CO2 laser marking is a clean process that minimizes environmental impact, aligning with sustainable development trends.

- Durability: Laser marks are directly applied to the fruit’s surface and are resistant to wear and tear, ensuring the longevity of the information.

- Traceability: By marking unique identification codes on fruits, the entire production and sales process can be traced, guaranteeing food safety.

- Enhanced Brand Image: Exquisite laser markings not only convey product information but also elevate product quality and brand image, fostering consumer trust.

- Versatility: CO2 laser marking machines can be applied to various fruit surfaces, from smooth apples to rough citrus, achieving high-quality marking results.

Laser marking technology has revolutionized the fruit industry. By providing precise and efficient marking on fruit surfaces, it not only enhances product value but also ensures a safer and more transparent consumer experience. As technology continues to advance, laser marking will find even broader applications in the fruit industry.

With over 16 years of manufacturing experience, Zixu has established a comprehensive laser product system, including marking machines, welding machines, cleaning processing centers, and CNC machining centers. To learn more about CO2 laser marking machines for fruit marking, contact us today.

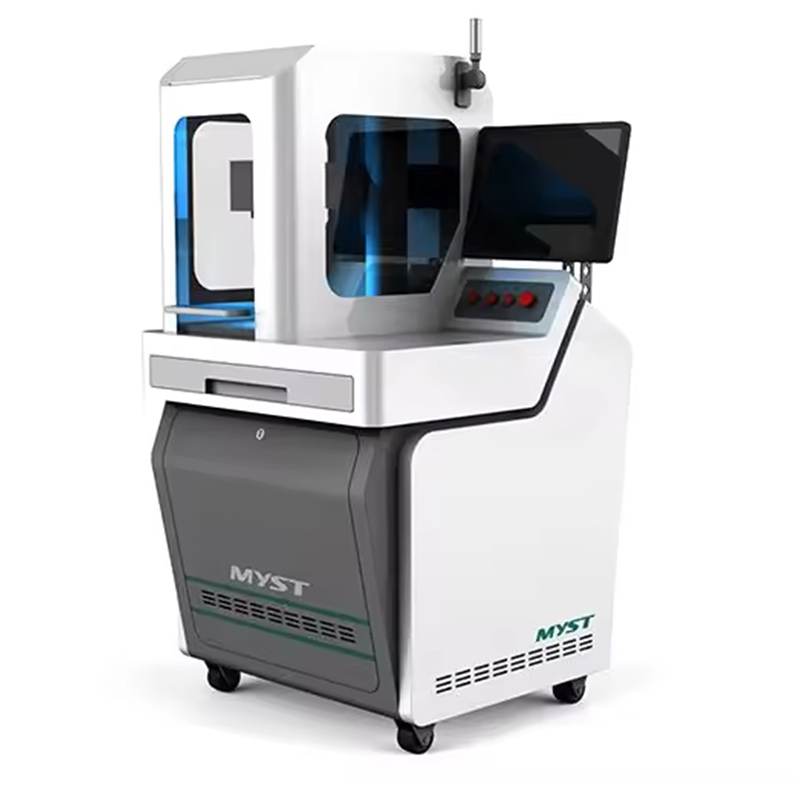

Recommended Products