Jewelry

Whether you want to add value by personalizing or marking your jewelry, have the flexibility to update a model, or need to expand production of a hot model, we offer a stable and efficient solution. With the exception of a few jewelry and watch brands that use peen engravers, the majority of precious metals and natural gemstones are engraved using a variety of laser devices. We have the experience to meet your potential needs from double-sided ring engraving to 3D sub-surface engraving of gemstones and diamonds.

Technologies For Jewelry

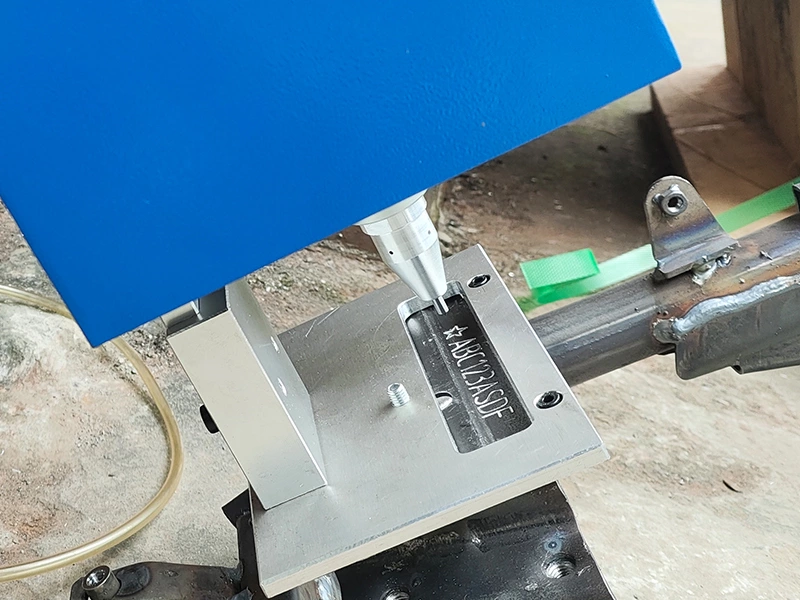

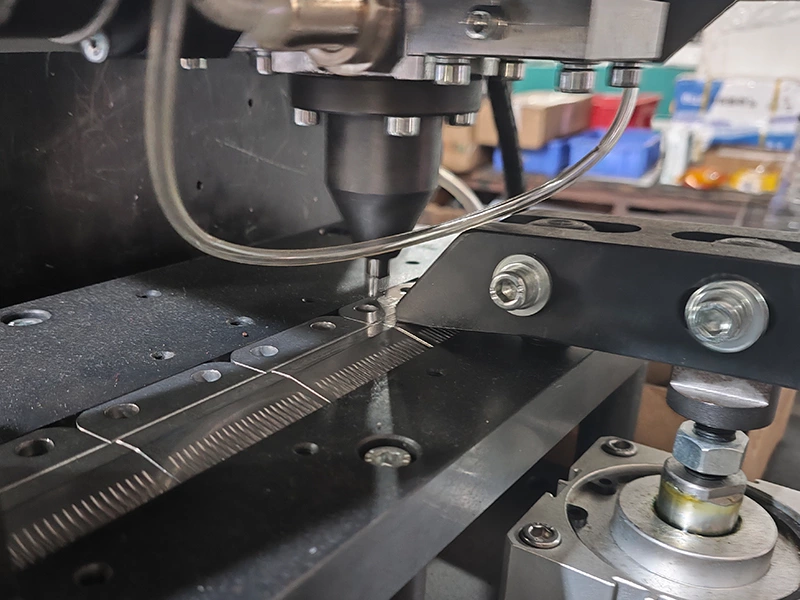

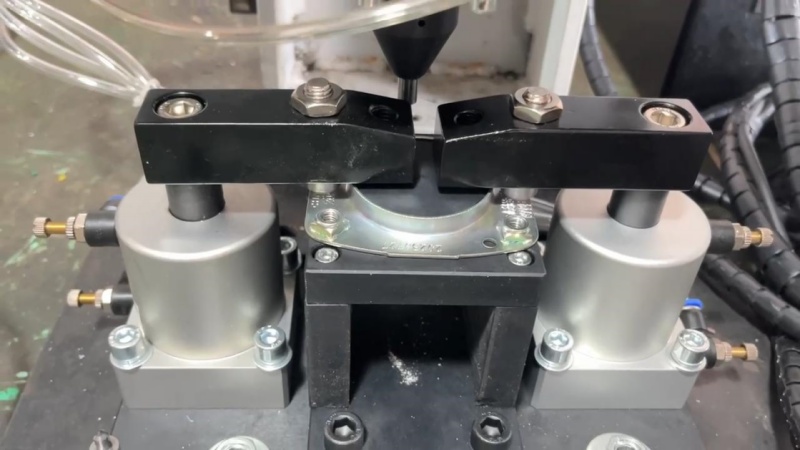

Generally speaking, needle engraving is not good for engraving small-sized precious metal jewelry such as rings and earrings, the main reason being that the compressed air is too strong and can damage the jewelry fixture for a long time, affecting the accuracy of the process and even leading to scrap. However, for flatter or larger sized jewelry such as cufflinks, tie clips, watch dials, etc., some of our high-end customers use a scribing machine to achieve unparalleled aesthetic engraving.

- Beautiful: our peen marking machine offer smooth mark edge and keep in primary color of metal especially by scribe, and no damage or burn on environ surfaces.

- Fast: to mark with same specific depth such as 0.3mm, our peen marking machine is 8~10X faster than a 100W fiber laser system;

- Depth: our peen marking machine offer 0.1~0.3mm depth in one pass, and able to precise repeat for deeper marks.

Laser engraving or marking is our most produced and shipped machine for jewelry applications, whether it is a slightly lower power personalized content marking in a retail jewelry store or bulk deep engraving for a jewelry manufacturer, from relatively inexpensive stainless steel, silver, ceramics, and crystals to precious gold, carat gold, platinum and emerald jewelry, we have a wealth of experience and solutions.

- Quiet: laser marking of metal also generates noise, especially deep engraving, but this is negligible compared to the peen marking process;

- Accuracy: Laser marking can mark metal in extremely small sizes, such as 0.03mm line width characters or graphics, which are impossible for peen marking;

- Visibility: Using MOPA fiber or UV laser for laser annealing instead of engraving for black or other color marking on metal workpieces with high contrast.

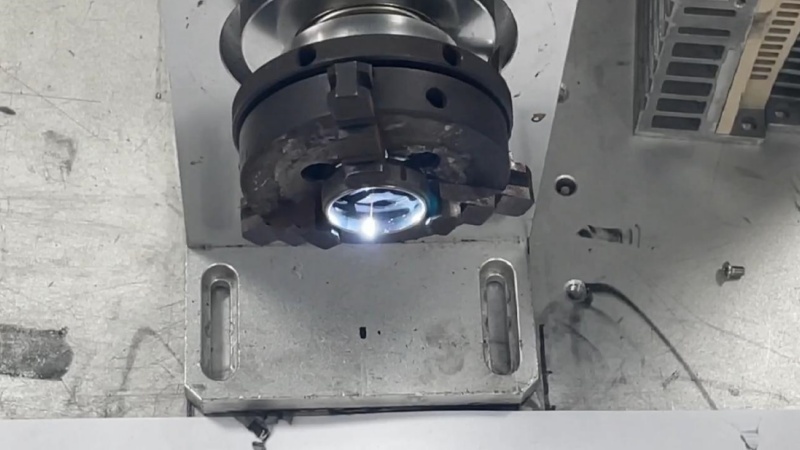

Despite the excellent precision of laser welding and the smallest weld marks, laser welding is more commonly used in the jewelry industry for dimensional adjustments or repair welding of damage to the raw material, and also by manufacturers of very few special shapes of jewelry, such as ‘stud’ rings.

- Precision: we use precise YAG laser welding machines to produce extremely small spots and weld marks;

- Purity: we use high pulse energy laser beam to melt the material a little bit and do not need feed wire, which avoid purity decrease;

- Easy to use: extremely consistent weld quality that requires less operator skill than traditional TIG manual welding.

Explore Our Machines For Jewelry

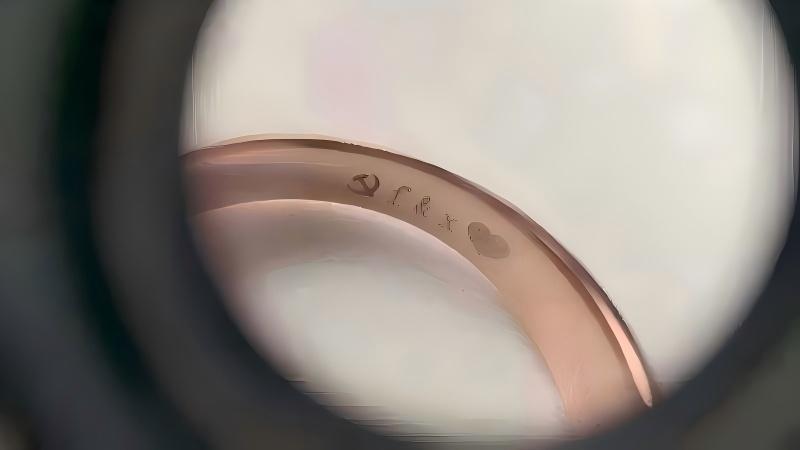

Engraving unique and permanent emotions for clients.

With the development of human civilization and economy, many people are looking for jewelry to commemorate important moments in their lives, such as wedding, birthday, birth and anniversaries of various important dates, and want to inscribe the emotional message of the time to be preserved forever. We listen to the needs of the jewelry and luxury goods industry for flexible customization, whether in metals such as gold or in precious materials such as leather, diamonds and crystals, we can provide the appropriate solution.

Enhance the uniqueness and counterfeit protection of your popular products.

By marking your jewelry with a unique serial number or data matrix (QR code) and recording it in a local information system such as MES, you can dramatically improve the traceability of your products, helping you to prevent counterfeiting and improve after-sales service. In addition, some manufacturers, such as watchmakers, can use MOPA fiber lasers to add unique and permanent color markings to the surface of common stainless steel or titanium parts.

Keep your customers feeling sensational for a lifetime

Accidents happen all the time, and whether it’s a broken necklace or earring, or a ring that’s become too tight or too loose over time, someone will always ask for a repair from the people who make or sell the jewelry. Our standardized jewelry welding machines make it easy to respond, deepening your connection with your customers and extending the reach of your brand.

Want an un art handing video demonstration on specialized material? Looking for a solution to your specialized environment or automatic process demand?