Jewelry & Dental YAG Laser Welder

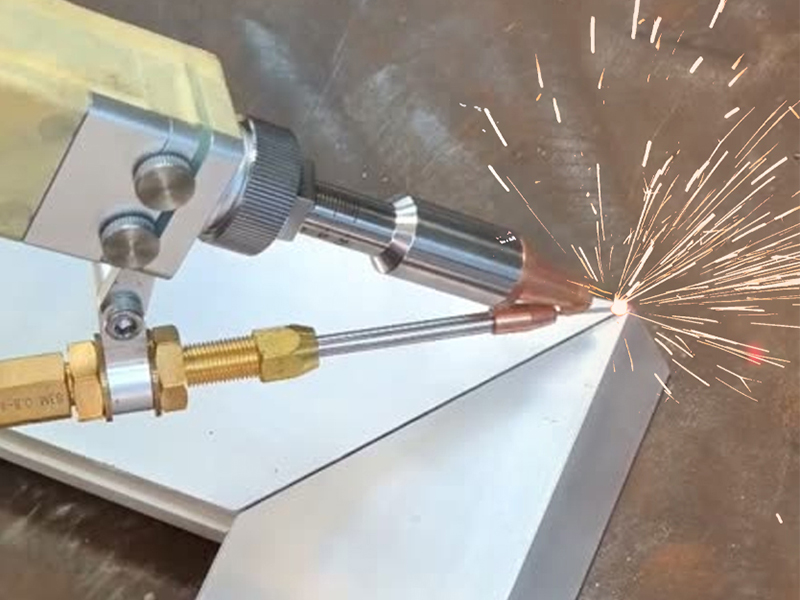

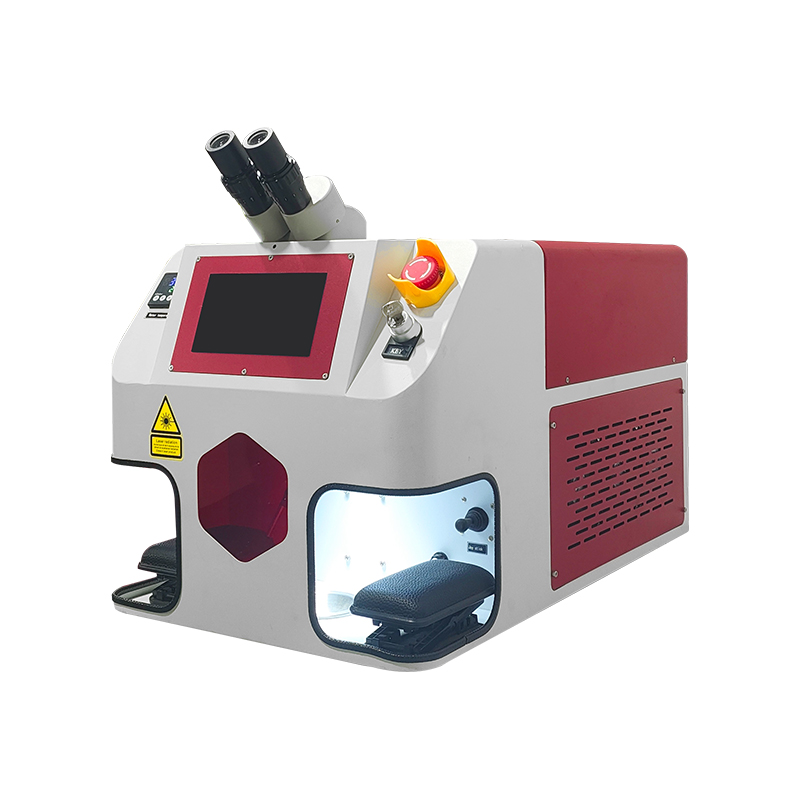

Since 2018, we’ve offered standard desktop and stand-alone precision YAG laser welders equipped with reliable lasers that deliver stable, long-lasting welding performance, whether it’s for precious metal jewelry, dental, or other small-volume, hand-held precision welding. The machines are now equipped as standard with an optical microscope, a CCD electron microscope and a touch screen that allows the user to monitor and adjust the weld position in real time to ensure perfect weld quality.

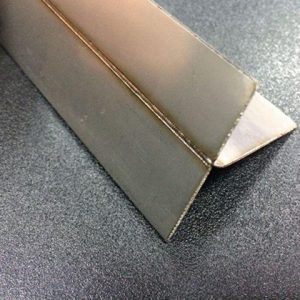

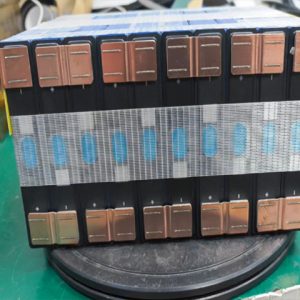

Our precision YAG laser welding machines do not need welding wires, but use high instantaneous energy laser pulse to melt metal in very small sizes, resulting in low visible weld marks with high weld strength, which are used for welding orthodontic braces in dental clinics, precision welding of thin plates of metal parts, etc. In addition, our precision YAG laser welding machines can be used to fabricate jewelry.

For product pricing, customization, or other inquiries:

Description

Technical data of our standardized Precise YAG laser welding machines

Choose from our standard machines below and slide to the right for more information, or contact us for a solution.

| Typical Appearance | Machine Type | Laser Type | Laser Wavelength | Laser Power | Laser Beam Quality | Power per Pulse | Frequency Scope | Pulse Width | Power Supply | Operating Environment | Storage Environment |

| Desktop | YAG | 1064±3nm | 80W/100W/120W/150W/200W | m²<1.2 | Up to 100J | 1~15Hz | 0.1~15ms | 100~240VAC, 50~60Hz | 10~40℃ or 50~104℉, RH10~84% no condensation | -10~60℃ or 14~140℉, RH10~84% no condensation |

| Stand-alone | 80W/100W/120W/150W/200W/300W/500W | Up to 250J |

Welding Samples

Clients who chose our Laser Welding Machine.

FAQs about our Laser Welding Machine

Want an un art handing video demonstration on specialized material? Looking for a solution to your specialized environment or automatic process demand?