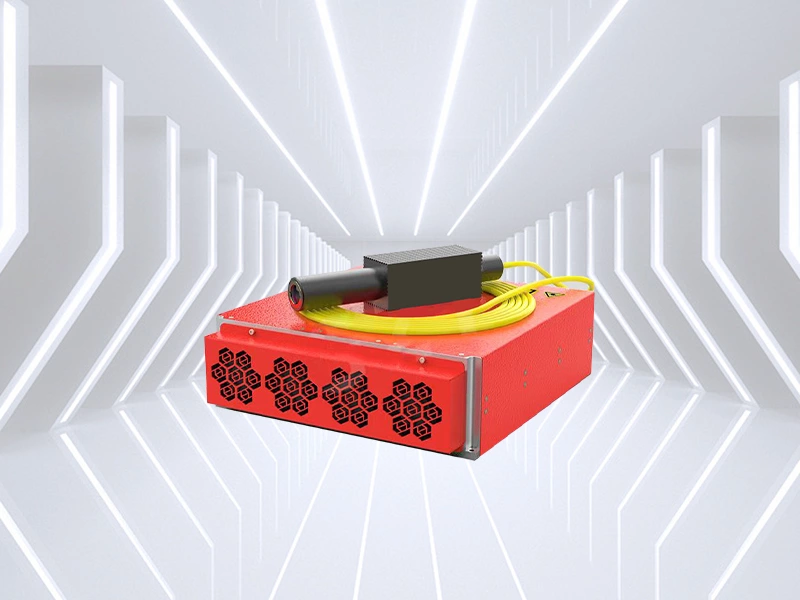

We always insist on providing our customers with the most reliable lasers from IPG, JPT, Raycus or MAX, and we have established good cooperation with these laser brands for many years. We are a strategic partner of JPT and Raycus, and we can even directly entrust them to carry out local repairs and after-sales service for defective lasers overseas.

Key Specification

| Laser Source Type | Fiber, CO2, UV, etc. |

| Laser Source Brand | IPG, JPT, Raycus, MAX, etc. |

| Average Power | 3~12000 Watts based on laser type. |

| Laser Wavelength | 355~1090nm |

| Work Temperature | 0~40℃ / 32~104℉ |

Consider the life cycle of your laser system, not the minimum threshold to meet demand

Generally, you need to select a specific laser type and power according to the actual purpose of using the laser system, but since the power of the laser source decays about 5% per year, we recommend that you select the corresponding reserve power according to the target service life if you intend to use it for a long period of time.

Availability more important than reliability for laser sources.

Although lasers are generally very durable and not easily damaged, due to the effects of the working environment, such as improper parameter settings, dust, high temperature, high heat, collision and other accidents, we recommend that you choose a laser source brand that has local after-sales service in your country to ensure that your business does not stop due to these accidents.

Choose the laser source that best suits your needs, not the one with the highest specifications.

Laser sources are developing at a rapid pace, with higher power, higher beam quality and faster and more refined laser processing, but laser sources are still similar to a consumable, don’t invest more money in power you don’t need, this is our advice to you, and we sincerely hope we can help your business be more successful.

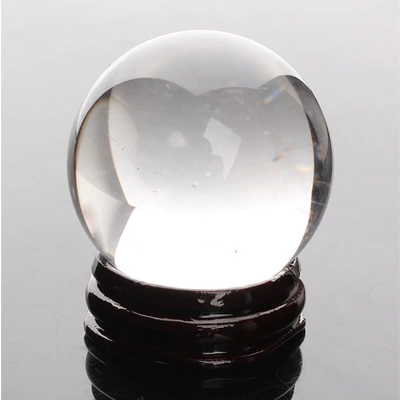

The Galvanometer is an important optical component in the laser industry, mainly used to control the position and direction of the laser beam. When selecting a galvo, it is necessary to consider the type and power of the supporting laser source, as well as the requirements for the size of the working area and the shape of the workpiece.

Key Specification

| Marking Speed | Up to 12000mm/s |

| Positioning Speed | Up to 23000mm/s |

| Writing Speed | Up to 600cps |

| Repeatability (RMS) | ≤138μs |

| Wavelength | 355nm/1064nm |

Availability more important than reliability for a laser galvo.

Although galvos are generally very durable, due to the effects of working environment such as dust, high temperature, high heat, collision and other accidents, we recommend that you choose a brand of galvos that has local after-sales service in your country to ensure that your business does not stop due to these accidents.

Choose the best galvanometer for your needs, not the one with the highest specification.

The optical glass lens industry has developed relatively slowly over the years, but the speed and precision of controllers and drive motors have developed rapidly. Galvos are still similar to a consumable, you should choose galvo based on the working range, precision and speed you need, and do not invest more money in the specification you do not need.

Maintain the galvanometer to ensure process quality and reduce cost of ownership.

The galvo is an extremely precise optical instrument containing a series of precision-machined optical glass lenses, please refer to the instruction manual for regular calibration and maintenance of your galvanometer, and timely replacement in case of failure to avoid major losses.

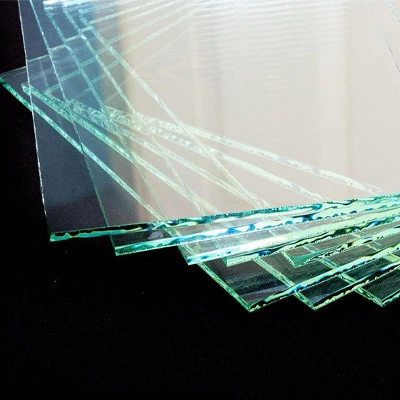

The field lens is located after the galvanometer in the optical path of the laser system which decided your laser work area, and the laser beam is refocused by the field mirror after the direction is determined by the galvo to improve the energy density of the laser work. When selecting a field lens, the type of laser source, the spot size by the galvo, and the final focusing distance must be considered; even equipped with collimated field lenses the laser beam must be focused before reaching the workpiece in order to work properly.

Key Specification

| Focus Length | 63~1450mm |

| Scan Area | Up to 900*900mm |

| Work Distance | 68~1420.8mm |

| M1/M2 Separation | 12.54~25.52mm |

| Fix Thread | M85 |

Availability more important than reliability for a laser field lens.

Although field lenses are generally very durable, due to the effects of working environment such as dust, high temperature, high heat, collision and other accidents, we recommend that you choose a brand of field lenses that has local after-sales service in your country to ensure that your business does not stop due to these accidents.

Choose the best field lens for your needs, not the one with the highest specification.

The optical glass lens industry has been developing slowly over the years. We recommend that you choose your field lens according to the type of laser you already have or have chosen, the power of the laser, the actual environment of the installation and the distance to be used, etc., or seek professional advice from us to avoid unwanted or unusable performance parameters.

Careful maintenance of your field lens will ensure the quality of your laser process and reduce costs over the life of your laser system.

The field lens is an extremely precise optical instrument containing a series of precision-machined optical glass lenses, please refer to the instruction manual for regular calibration and maintenance of your field lens, and timely replacement in case of failure to avoid major losses.

What do you need to consider before you ask a laser spare component for replacement?

If you already have a laser system in good condition, but it is not working properly due to optical degradation or accidental damage, simply purchase the original model. However, if the original model has been discontinued, please choose an iteration of the same brand and make sure the compatibility parameters are the same as before. If you are still in doubt about the type and compatibility of your spare parts, you can get free professional advice online.