Laser Rust Removal vs. Traditional Rust Removal: How to Choose a Rust Removal Method

Rust, the common name for iron oxide, is a pervasive problem affecting various industries, from automotive and aerospace to construction and marine. Left unchecked, rust can compromise structural integrity, diminish aesthetic appeal, and lead to costly repairs or replacements. While traditional rust removal methods have been employed for decades, laser cleaning technology has emerged as a powerful and increasingly popular alternative.

This article explores the various traditional rust removal techniques, delves into the characteristics of laser rust removal, and provides a comparative analysis to help you choose the most appropriate method for your specific needs.

What are the Traditional Rust Removal Methods?

Several traditional methods exist for removing rust, each with its own set of advantages and disadvantages.

Manual Rust Removal

Including tools such as scrapers, hand hammers, steel brushes, and grinding wheels, this method involves treating rust on metal surfaces through actions like hammering, chiseling, grinding, and scraping. It aims to achieve rust removal through physical vibration and friction.

- Advantages: Low initial cost, simple tools, suitable for small areas.

- Disadvantages: Labor-intensive, time-consuming, inconsistent results, can damage the underlying material if not done carefully, ineffective for deeply embedded rust.

Mechanical Rust Removal

Mechanical rust removal involves using tools such as hand-held grinders, electric brushes, and rust removal guns to remove rust and stains through physical impact and friction. Among them, blasting and shot blasting are the two most widely used methods.

- Advantages: Faster than manual removal, effective for larger areas, can remove thicker layers of rust.

- Disadvantages: It will generate dust and debris, which will pollute the environment. Improper use may damage the surface and require special equipment, which may not be suitable for precision or complex parts. In particular, the sandblasting method requires careful selection of the medium to avoid damage to the substrate.

Chemical Rust Removal

This method involves applying chemical solutions, such as phosphoric acid, hydrochloric acid, or chelating agents, to dissolve or loosen rust. These chemicals react with the rust, converting it into a more stable compound or making it easier to remove mechanically.

- Advantages: Can reach hard-to-access areas, effective for removing thin layers of rust, relatively easy to apply.

- Disadvantages: Can be hazardous if not handled properly, requires careful surface preparation, may leave chemical residues, disposal of chemicals can be environmentally problematic, some chemicals can be corrosive to the base metal.

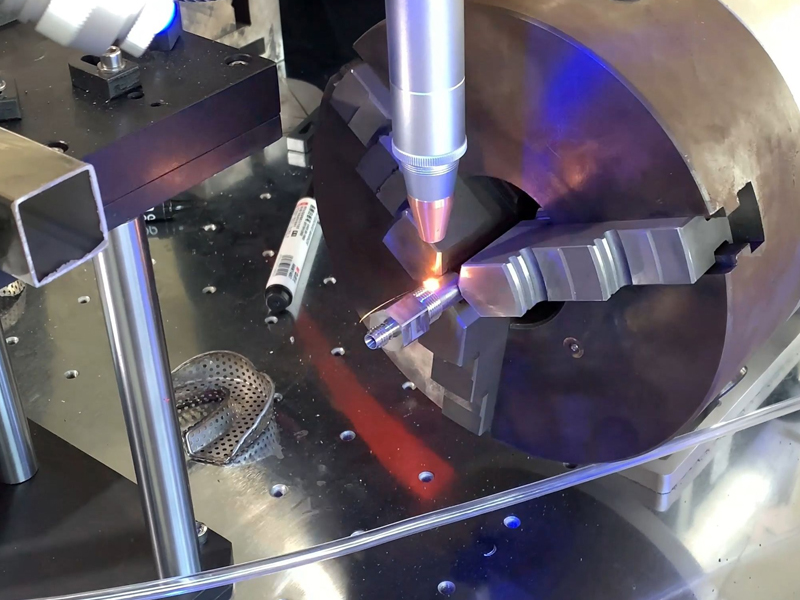

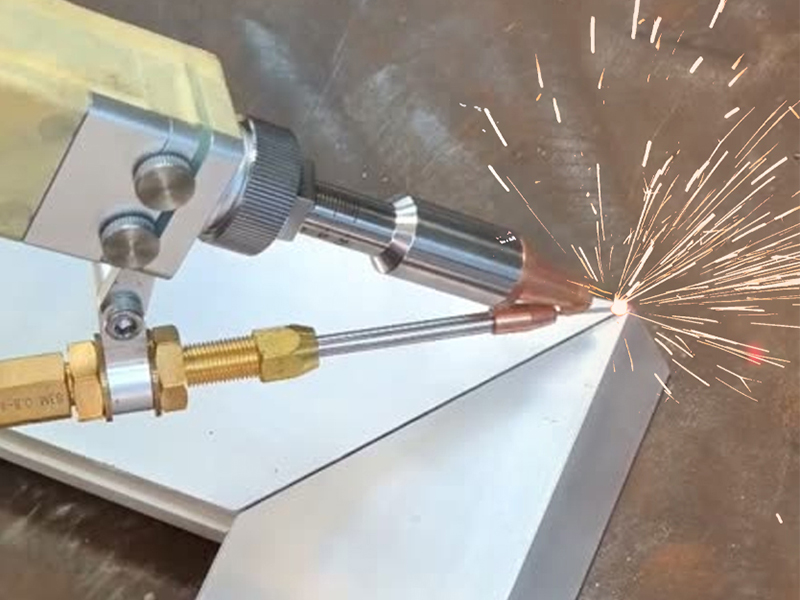

Characteristics of Laser Cleaning Machine Rust Removal

Laser cleaning utilizes a focused beam of light to vaporize or ablate rust and other contaminants from a surface. The laser’s energy is precisely controlled to target the rust layer without damaging the underlying material.

Advantages:

- Non-contact Cleaning: Lightweight design, integrated, easy to carry manually to any work area, to achieve target selection and positioning cleaning, non-contact cleaning work, no damage to the substrate, no pollution, no need for subsequent treatment.

- Fast and Efficient: Efficient, fast, and low cost, the thermal and mechanical loads generated on the substrate are small, and the cleaning is non-destructive; safe and reliable, without harming the health of operators.

- Easy to Automate: It can move freely, can be combined with CNC technology, and can also achieve selective automatic scanning, strong cleaning ability, safety and reliability, without harming the health of operators, etc., to achieve remote control cleaning.

- Multi-functionality: Laser cleaning can be used for a variety of materials, including metals, plastics, ceramics, and composites.

- Precision and Selectivity: Laser cleaning can accurately target rust layers, even in complex areas, without affecting the base material. The laser’s wavelength and power can be adjusted to selectively remove rust while leaving the underlying material intact.

Disadvantages:

- High Initial Cost: The initial investment in laser cleaning equipment can be significant.

- Safety Concerns: Laser cleaning requires proper safety precautions, including eye protection and ventilation, due to the potential hazards of the laser beam and any fumes generated.

- Not Suitable for All Materials: While versatile, laser cleaning may not be suitable for all materials or types of rust. Some materials might be more susceptible to laser damage, and certain types of rust might be more resistant to laser ablation.

Laser Rust Removal VS Traditional Rust Removal: How to Choose a Rust Removal Method

| Feature | Traditional Rust Removal | Laser Cleaning |

| Precision | Varies; can be imprecise, especially in tight areas. | Highly precise; targets rust without affecting the base material. |

| Selectivity | Limited; may remove base material along with rust. | Highly selective; adjusts wavelength and power to remove only rust. |

| Accessibility | Can be challenging for hard-to-reach areas. | Can access even complex or difficult-to-reach areas. |

| Base Material | Potential for damage, especially with aggressive methods. | No damage to the base material; non-contact process. |

| Speed | Can be slow and labor-intensive. | Fast and efficient; significantly reduces cleaning time. |

| Cost | Lower initial cost for equipment and materials. | Higher initial investment, but lower long-term operational costs due to speed and efficiency. |

| Environmental Impact | May produce waste or use harmful chemicals. | Environmentally friendly; reduces waste and eliminates the need for chemicals. |

| Automation | Difficult to automate. | Easily integrated with CNC technology for automated scanning and cleaning. |

| Material Versatility | Varies depending on the method. | Can be used on a wide range of materials (metals, plastics, ceramics, composites). |

| Surface Finish | May require additional steps to achieve desired finish. | Can achieve specific surface finishes without damaging the base material. |

Summation

Traditional rust removal methods like manual, mechanical, and chemical cleaning have their place, particularly for small-scale projects or situations where cost is a primary concern. However, laser rust removal has emerged as a superior alternative for many applications, offering numerous advantages in terms of precision, efficiency, environmental impact, and versatility.

While the initial investment in laser cleaning equipment is higher, the long-term benefits, including reduced labor costs, improved quality, and minimized environmental impact, often make it a worthwhile investment. By carefully considering the factors outlined in this article, you can make an informed decision about the most appropriate rust removal method for your specific needs.

Zixu offers high-quality industrial continuous laser cleaning machines and pulsed laser cleaning machines with a wider range of applications and more refined cleaning effects. Laser cleaning utilizes a high-energy laser beam to evaporate rust, paint, coatings, oil, ink, etc. from metal and non-metal surfaces, with no mechanical wear, no cleaning agent consumption, and no harmful emissions. If you have equipment needs, please feel free to contact us for pricing.

Recommended Products