Laser vs. Dot Peen: Which Gas Cylinder Marking Technology Is Better?

Gas cylinders are critical for storing and transporting compressed gases used in industries ranging from healthcare to manufacturing. Proper identification of these cylinders is non-negotiable: markings must be permanent, legible, and compliant with safety standards like ISO 13769 or DOT regulations. Two dominant technologies—laser marking and dot peen marking—are widely used for this purpose. But which is better suited for gas cylinder marking? This article compares their mechanisms, performance, and applications to help you make an informed decision.

What Are Laser Marking and Dot Peen Marking?

Laser Marking

Laser marking is a non-contact method that uses a high-intensity laser beam to alter the surface of the material. The beam either removes material, changes its color through heat, or engraves it at a micro level to produce high-contrast, permanent marks.

Types of laser marking used in gas cylinder applications include:

- Fiber laser – ideal for metals, offering high precision and speed.

- CO₂ laser – suitable for organic or non-metallic materials (less common for gas cylinders).

- UV laser – precise but less common due to cost.

Laser systems produce marks by vaporizing material, oxidizing surfaces, or inducing color changes. The result is a high-contrast, wear-resistant mark without physical contact.

视频:https://youtu.be/SGqX-P9LUuM?si=OtUngATvK8IACll9

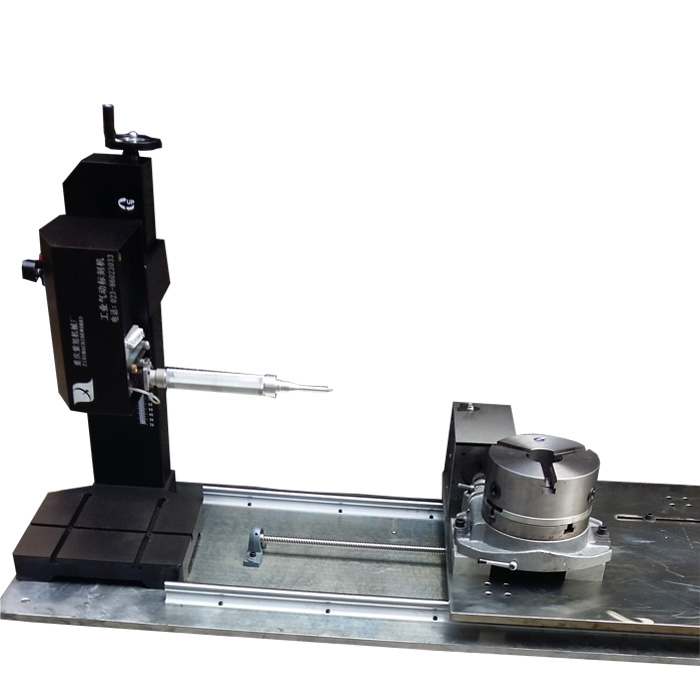

Dot Peen Marking

Dot peen marking (also called pin marking) uses a mechanical stylus or pneumatic pin to indent the material surface. It creates a series of small dots that form letters, numbers, and symbols by rapidly striking the surface.

It’s a contact-based method and has been widely used for heavy-duty marking of metal components, including gas cylinders, due to its durability and deep penetration.

Core Performance Showdown: Laser vs. Dot Peen

Let’s compare the two technologies across key performance criteria to determine which excels in different aspects:

| Performance Aspect | Laser Marking | Dot Peen Marking |

| Marking Quality | High resolution, clean and clear marks | Coarse marks, less refined appearance |

| Depth of Marking | Shallow to moderate (adjustable) | Deep marking ideal for harsh environments |

| Durability | Excellent, especially fiber lasers | Extremely durable, withstands extreme wear |

| Speed | Fast marking, especially for large batches | Moderate, slower on large content |

| Noise Level | Silent | Noisy due to mechanical impact |

| Maintenance | Minimal | Requires periodic pin or stylus replacement |

| Material Compatibility | Most metals and alloys | Metals only (preferably steel and aluminum) |

| Automation Integration | Easy to automate with software systems | Possible, but limited flexibility |

| Initial Investment | Higher cost, especially fiber lasers | Lower entry cost |

Application Scenarios: Where Each Technology Excels for Gas Cylinders

6.jpg)

Both technologies can be used for gas cylinder marking, but their performance varies depending on the specific application environment, budget, and technical requirements.

Laser Marking is the preferred choice when:

- High-resolution and intricate markings are necessary, such as small, scannable 2D barcodes (Data Matrix codes) for detailed tracking, and complex logos.

- A clean, aesthetically pleasing, or high-tech look is desired for branding purposes.

- Marking sensitive materials where the non-contact nature minimizes stress on thinner-walled or specialized alloy cylinders.

- High-volume manufacturing lines demand speed and efficiency with variable data marking.

- Seamless integration with sophisticated digital tracking and quality control systems is required.

- Applications involve clean environments like automated production cells.

- Cylinders have limited marking space requiring fine, high-resolution codes or QR codes.

Dot Peen Marking is the preferred choice when:

- Deep, highly durable markings are essential for cylinders subjected to harsh environments, repeated handling, and potential repainting, ensuring legibility even with surface damage.

- Cost sensitivity is a major factor, as it offers lower initial investment and running costs for high-volume marking where extreme precision isn’t critical.

- Simple, robust identification is the primary need for basic serial numbers, batch codes, and pressure ratings requiring permanent visibility.

- Marking uneven or slightly contaminated surfaces where the pin’s impact force can penetrate minor imperfections.

- Regulations mandate a specific depth of marking.

- Field marking or operations in harsh or outdoor environments are common.

- Marking thick-walled or painted cylinders requiring deep indentation.

- Small-scale operations or businesses with tighter budgets are involved.

Making the Right Choice: Factors to Consider for Your Gas Cylinder Marking Needs

When deciding between laser and dot peen technology, consider the following factors:

- Marking Requirements

Do you need deep engraving for extreme durability or precise, readable codes for scanning? - Production Volume

Laser machines are better suited for high-speed, automated environments. - Budget

Dot peen machines are more affordable upfront, while lasers may save more long term with lower maintenance. - Surface Condition

Rough, oily, or painted surfaces may be better suited for dot peen machines. - Automation and Integration

Laser systems are typically easier to integrate into Industry 4.0 smart manufacturing environments. - Compliance Requirements

Some regulations may require specific types of markings (depth, durability, legibility), influencing your choice.

No single technology is universally better—it depends on the unique combination of technical, operational, and financial factors relevant to your business.

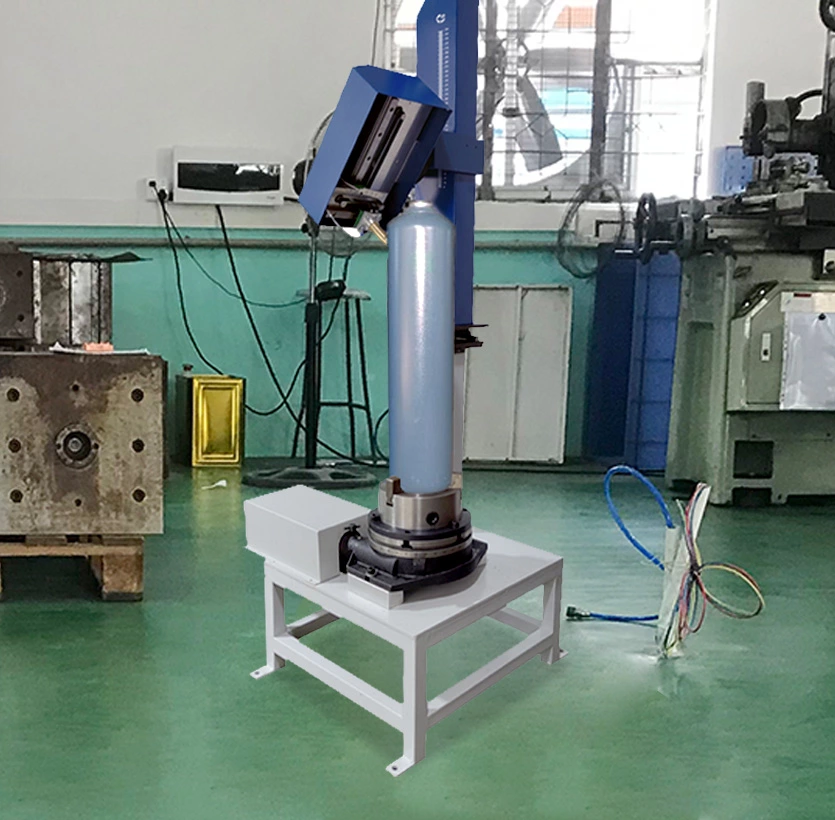

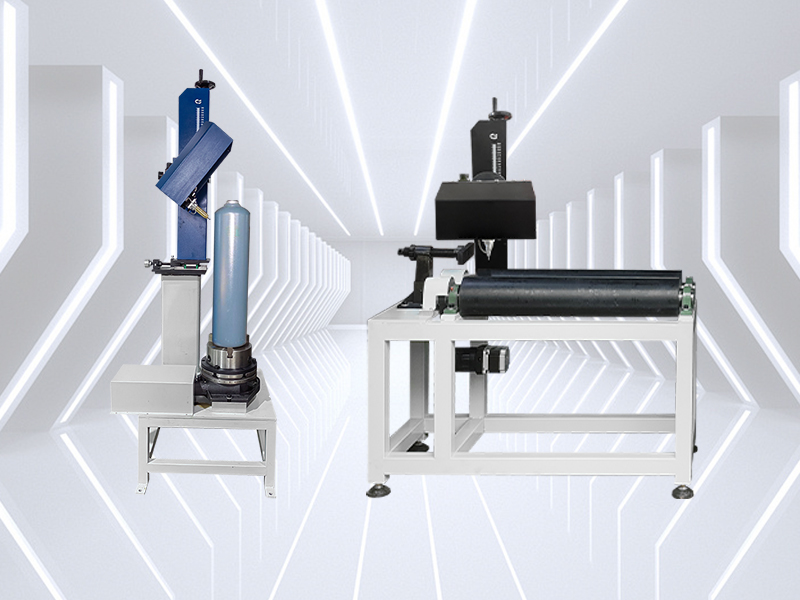

Explore Zixu Range of Laser and Dot Peen Marking Machines

At Zixu, we understand the complexities of gas cylinder marking across different industries and compliance standards. That’s why we offer both laser marking machines and dot peen marking systems, each engineered with:

- High marking precision and stability

- Customizable software and marking content

- Robust build quality suitable for industrial applications

- Support for curved surfaces and various gas cylinder diameters

Both laser and dot peen technologies offer distinct advantages for gas cylinder marking. Laser technology excels in precision and speed, while dot peen technology offers ease of operation and cost-effectiveness. Your choice will depend on your production needs, material types, and compliance requirements.

For future-proof solutions, explore Zixu’s versatile range of marking machines. Whether you prioritize cutting-edge laser accuracy or rugged dot peen durability, we have the tools to ensure your gas cylinders meet global standards safely, efficiently, and economically.

Recommended Products