Thanks to the mass production and use of fiber lasers in recent years, handheld laser welding machines have become affordable and cost-effective for small and medium-sized businesses, and are gradually gaining popularity in a variety of industries due to their reliability, low maintenance, low consumption, and consistent weld quality. Compared to conventional TIG and MIG welding, laser welding requires less welding skill, is faster, consumes no electrodes, and is safer for people and the environment.

Key Specification

| Wavelength | 1064nm |

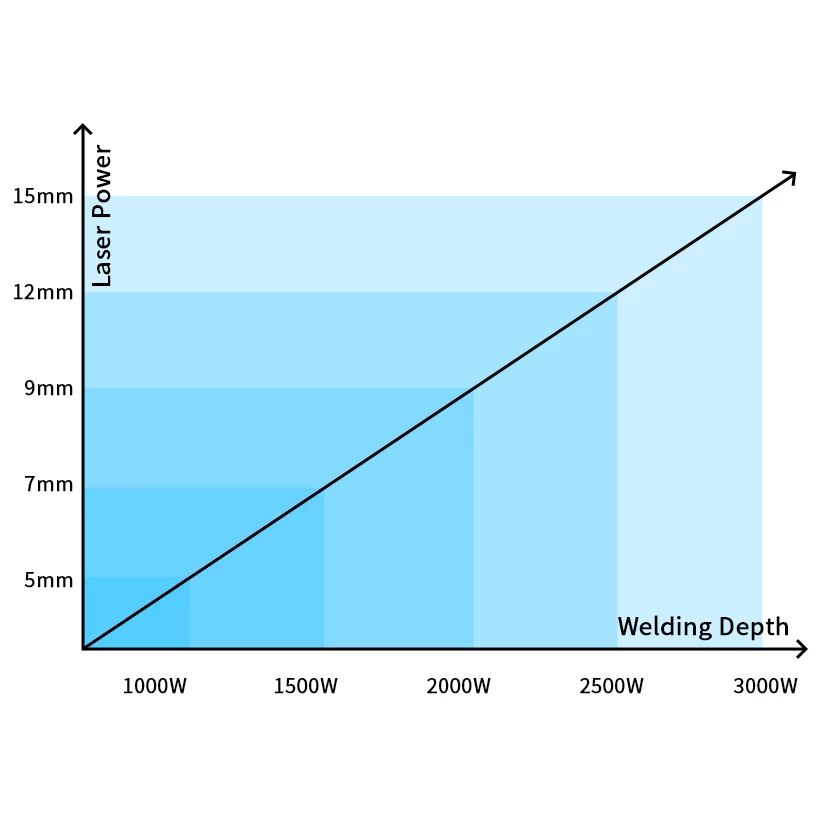

| Laser Power | 1000W/1500W/2000W/3000W |

| Duration | ≥100,000 working hours |

| Max Welding Depth | Up to 6mm on one site |

| Working Temperature | 0~45℃ or 32~104℉ |

Maximize your laser marking productivity.

Over the years, we have worked with a wide range of customers in a variety of industries, from automotive to small batch production of small artifacts, for whom we have designed and manufactured thousands of products with varying degrees of customization, maximizing the efficiency of your marking productivity with our extensive experience.

Accelerate your welding business, with lasers.

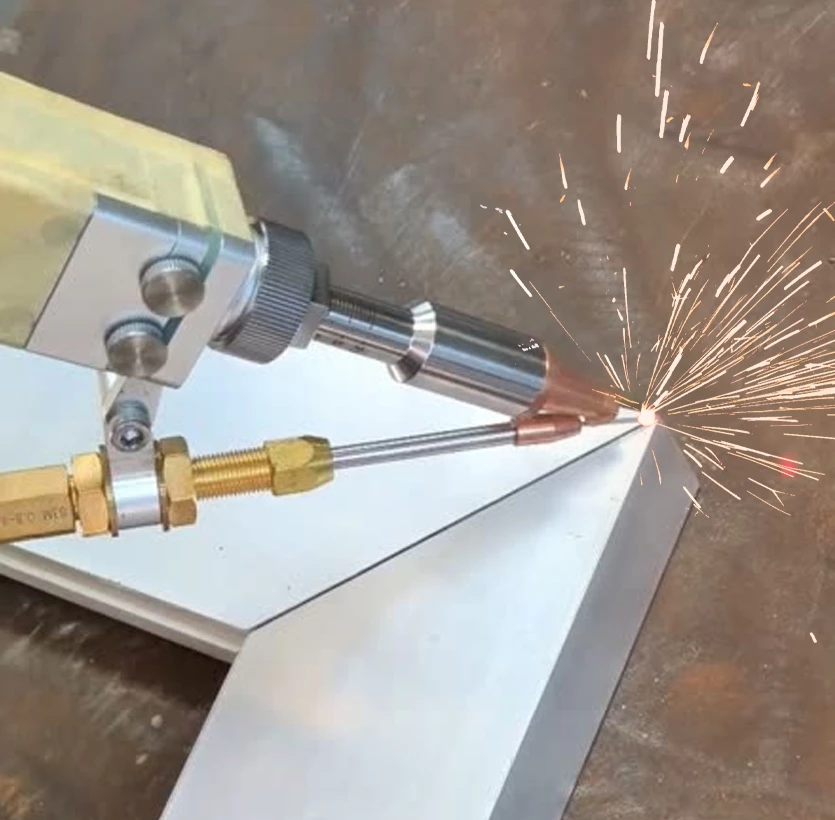

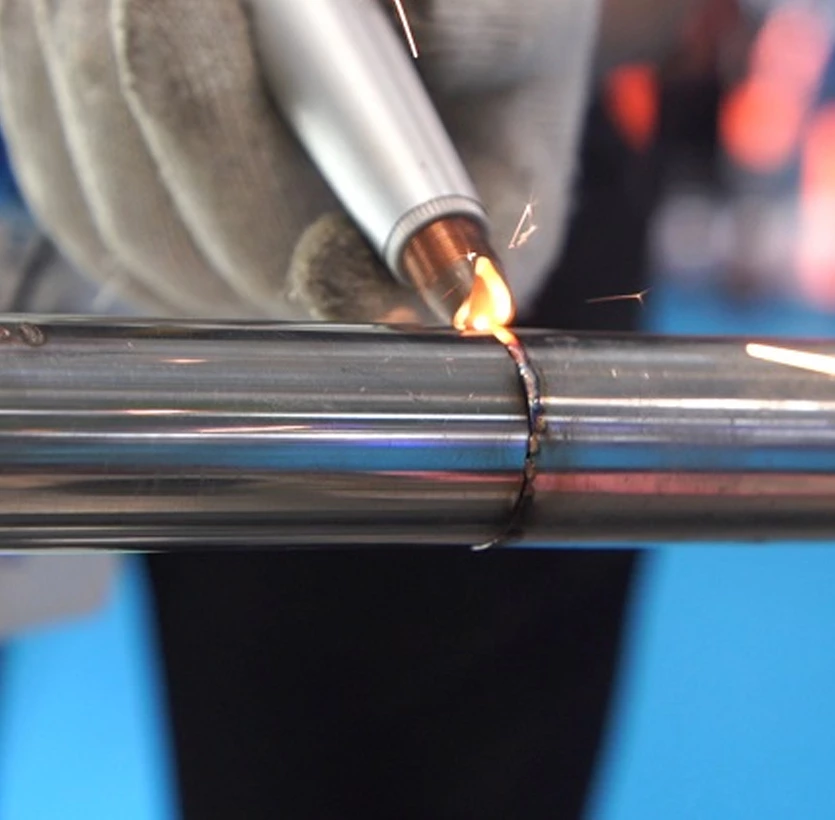

The most popular application for handheld laser welders is in the home improvement industry, whether it be custom doors, beds, fences, stair railings, etc. The most common application for handheld laser welders is in the home finishing industry. Compared to a small TIG welder, a handheld laser welder can achieve 5 to 10 times faster welding speeds at various power levels, while producing smoother weld marks and eliminating the need for polishing and grinding.

Multi-tasker for small business.

Due to the structure and principle of the handheld laser welding machine, it is possible to have an entry-level metal cutting and descaling capability by simply changing the gun head accessory, i.e. the so-called 3-in-1 or 4-in-1 multifunctional laser welding machine (some companies advertise weld mark cleaning as a separate function). This allows our handheld laser welding customers, especially small and medium-sized businesses in the advertising and finishing industries, to expand their business opportunities.

Friendly to environment and individual.

Our handheld laser welders eliminate the use and consumption of electrodes and shielding gas compared to TIG or MIG, drastically reduce airborne particles and odors when welding processed metals, ensure the health of your personnel (tips: please wear anti-laser goggles), and dramatically reduce the full-cycle carbon footprint, adding value and sustainability to your business.

We offer a standard line of laser jewelry & dental welders that use reliable YAG diode lasers to produce a very small spot, leaving the smallest possible weld marks to ensure that welded precious metal rings, necklaces and earrings maintain their grammage and aesthetic appearance, in addition, the use of no additional solder eliminates the loss of precious metal purity due to impurities. The series of welding machines are semi-enclosed structure, with chip collecting box, so you can collect precious metal chips for recycling. Our YAG welders are equipped with microscope and CCD monitor, so you can easily adjust the welding process to achieve the best welding results.

Key Specification

| Wavelength | 1064nm |

| Laser Power | 100W/120W/150W/200W |

| Laser Beam Diameter | 0.1~2mm adjustable |

| Positioning | 10X microscope and 3X CCD monitor |

| Working Temperature | 0~35℃ or 32~95℉ |

Keeps good for you.

Whether you are repairing a broken necklace or adjusting the diameter of a ring or bracelet, the most important thing is to maintain the original appearance. While it’s impossible to achieve a seamless result like melting and re-casting, our YAG laser jewelry welders produce low visible welds that are undetectable to the wearer, so they won’t interfere with your memories.

Done the job, reliable and stable.

We have equipped our jewelry laser welders with a built-in chiller to maintain a stable laser beam and spot energy per pulse, even during long hours of use. You can also use a microscope or real-time CCD monitor to see what is happening, and you can quickly adjust configuration settings on the touch screen. All you need is a steady pair of hands to keep it all going.

Sustainable growth for your business.

Our jewelry laser welders use only electricity (although inert gas is recommended), so in the long run you can save a lot on consumables such as solder wire, inert gas, and even laser safety goggles. In addition, you can collect jewelry welding chips and recast them for reuse. Plus, we use YAG lasers that last 5+ years and offer lifetime online technical support to help you succeed.

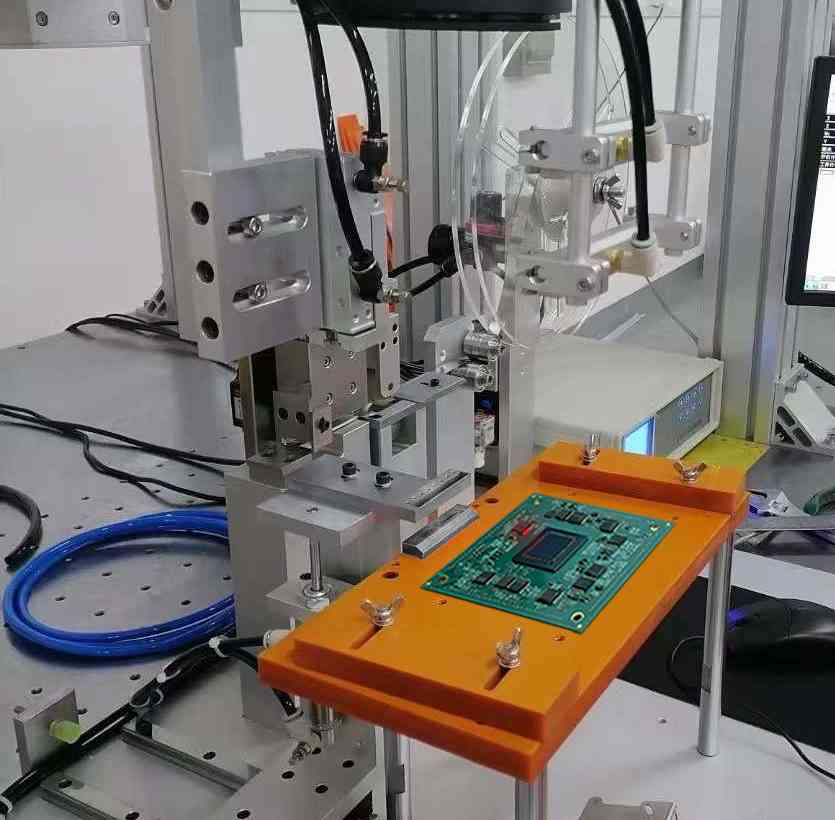

Over the years, we have leveraged our extensive implementation and engineering experience to provide hundreds of different automated welding solutions for our customers’ diverse automated laser welding needs, and have developed standardized multi-axis automated platform laser spot welders and galvanometer laser welders. In addition to the standard model itself, we also offer the most valuable and reliable solutions for your automated loading and unloading needs, workpiece shape, weld depth and seam width.

Key Specification

| Wavelength | 1064nm |

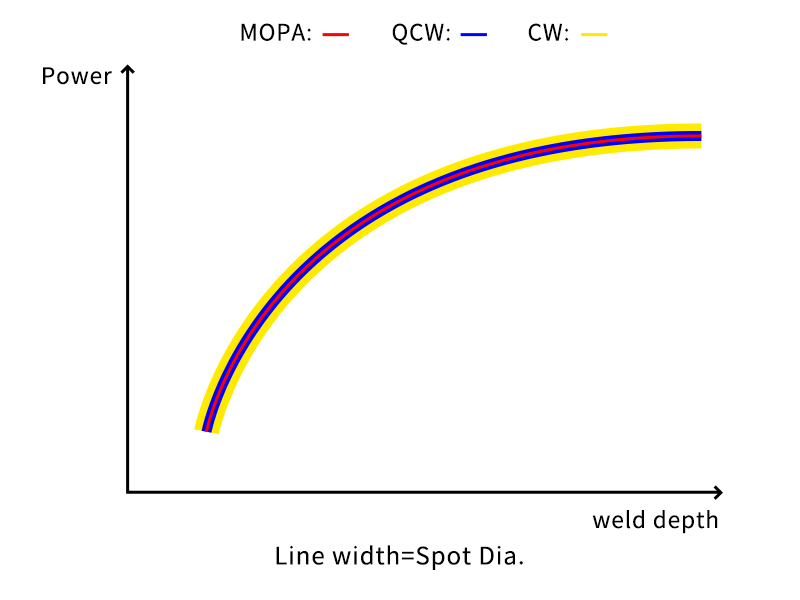

| Laser Model | CW/QCW/Pulse Fiber |

| Power | YAG: 200~500WCW: 1000~6000WQCW: 150~300WMOPA: 100~1000W |

| Multi-Axis Control | 3/4/5/6 Axis |

Efficient and precise welding

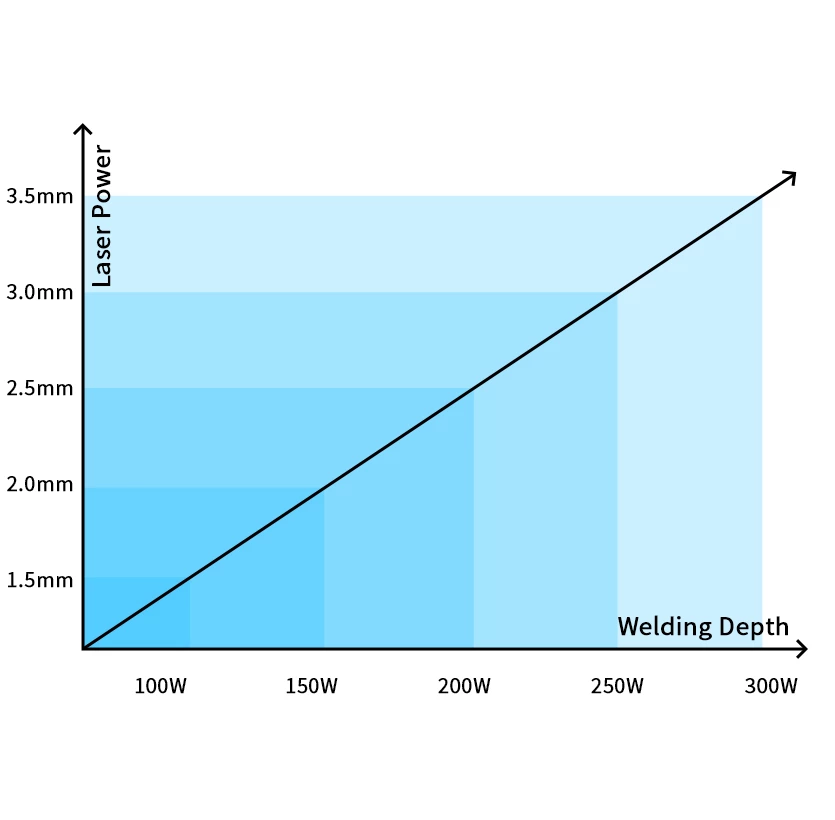

Even for high-density welding processes such as printed circuit boards (PCBs), our high-precision laser soldering machines enable precise soldering with a minimum gap of 0.1 mm and prevent thermal damage to the workpiece. At the same time, we have the flexibility to switch between different workpieces by changing engineering drawings. In addition, our laser welders can be used in conjunction with conveyors, fixtures or robots to achieve fully automated loading and unloading, further increasing efficiency.

Spend a little more to do a lot more

For high-value workpieces such as aircraft structural parts, automobile frames, printed circuit boards (PCBs), etc., the use of automated laser welding creates more value in the long run by reducing the amount of energy and money spent on rework or scrapping. Consistent product reliability, safety, etc. can further enhance your brand reputation, goodwill, and even market capitalization.

Standardize your welding process and quality

Whether you are in the aerospace, automotive, energy, instruments, consumer electronics, appliance, medical devices, or metal hardware industries, high-volume customers are often looking for automated welding solutions to increase the throughput of their welding processes, ensure consistent weld strength and depth, minimize the impact of the human factor on weld quality, and improve the aesthetics of their welds.

Why Choose Zixu Laser Welding Machine?

Our fast and accurate with a variety of automatic level welding solutions work on a wide range of industries including automotive, electronics, appliance, metal hardware, home finishing and more.

Precision and legible

The weld quality of a laser welder is more consistent than a TIG or MIG welder and requires less skill;

Universal with weld strength

From aerospace to marine, laser welding provides consistent depth and strength with excellent material compatibility;

Environment friendly

Compared to TIG or MIG welding, laser welding produces much less wire consumption, noise, airborne particles and pollution;

Nimble deployment

Our laser welders are available in standard models as well as with optional modules or robots for heavy-duty applications.

Clients who chose our laser welding machines?

Want an un art handing video demonstration on specialized material? Looking for a solution to your specialized environment or automatic process demand?