Metallic Material Application

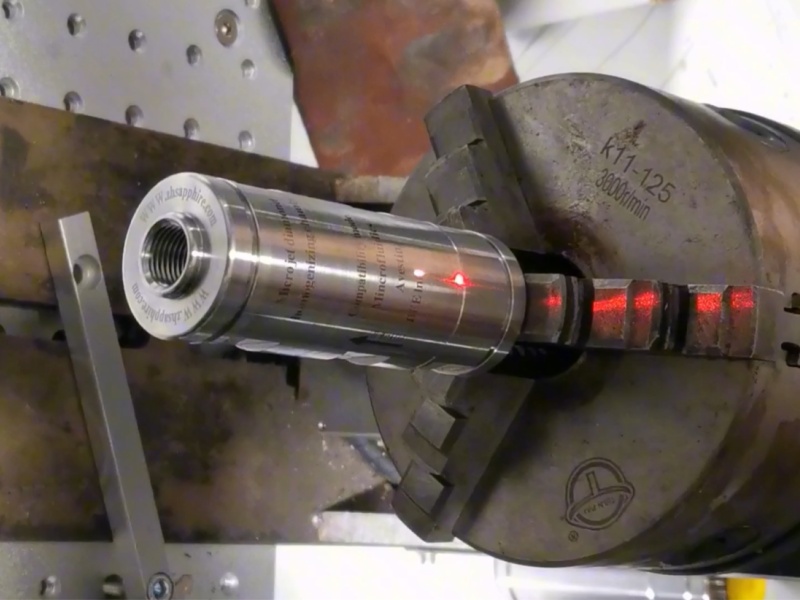

Over the years, we have provided highly customized automated metal peen marking, laser marking & engraving, welding, and cleaning machines and have accumulated extensive experience in process and automation, especially for industrial metal marking. Specifically for automotive VIN marking and all types of industrial Direct Part Marking (DPM), we offer all machines and solutions from conventional needle to laser.

Our Metal Processing Technologies

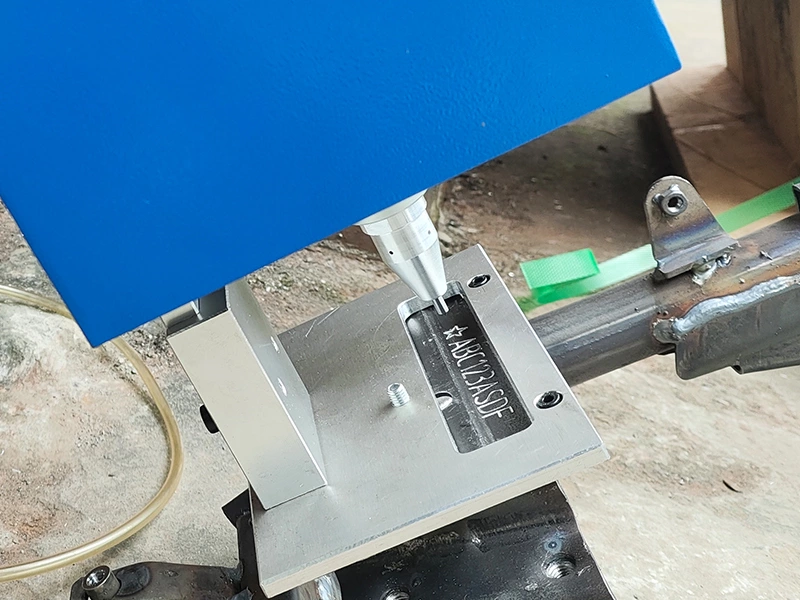

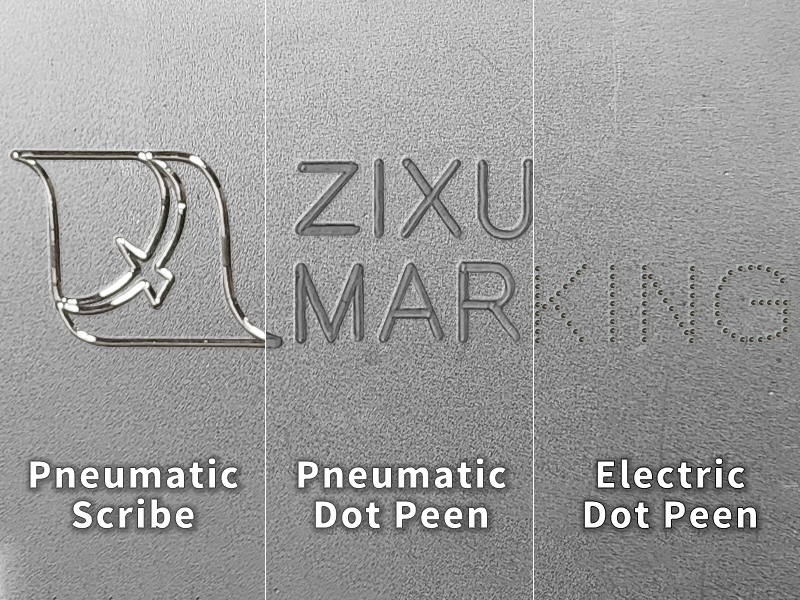

Which includes Dot Peen and Scribe methods to produce dot or continuous line mark, Dot Peen means hard alloy needle tip powered by compressed air or electricity to punch the metal workpiece in high frequency, and Scribe uses hard alloy or diamond needle tip powered by compressed air to carve on workpieces. Basically, peen marking is an efficient marking method for metal with high speed and high depth for a permanent mark.

- Fast: to mark with same specific depth such as 0.3mm, our peen marking machine is 8~10X faster than a 100W fiber laser system;

- Depth: our peen marking machine offer 0.1~0.3mm depth in one pass, and able to precise repeat for deeper marks;

- Beautiful: our peen marking machine offer smooth mark edge and keep in primary color of metal especially by scribe, and no damage or burn on environ surfaces.

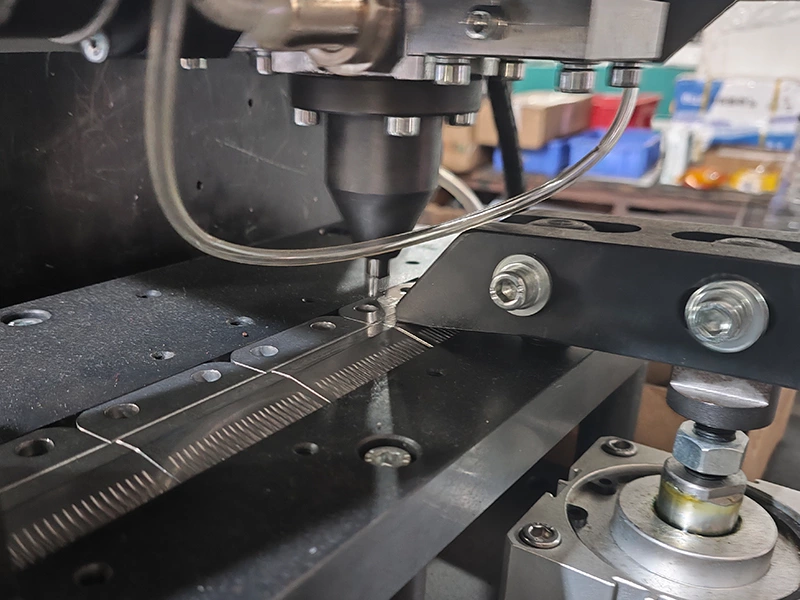

Because laser marking requires no physical contact, it produces less noise and metal debris than traditional peen marking, and can be configured to fit more complex shapes. And because there are no consumables such as marking needles, laser markers can be installed and operated at high loads for long periods of time, requiring only periodic calibration to maintain consistent marking quality and efficiency.

- Quiet: laser marking of metal also generates noise especially deep engraving, but this is negligible compared to the peen marking process;

- Accuracy: Laser marking can mark as small as 2*2mm square UDI code or 0.03mm line width characters, which is impossible for peen marking;

- Visibility: Using MOPA fiber or UV laser for laser annealing instead of engraving for black or other color marking on metal workpiece with high contrast.

In recent years, the use of lasers as an alternative to TIG and MIG welding for all types of metals has become a trend. Compared to TIG and MIG welding, laser welding provides a smoother and more consistent power output, is easier to automate with CNC multi-axis tables or robots, and can be used with a galvanometer welding system for ultra-precise, non-contact welding.

- Easy to use: extremely consistent weld quality that requires less operator skill than TIG and MIG welding;

- Precise: QCW or MOPA fiber laser welding system produces extremely small spots and weld marks for high-precision welding of thin sheets, films, electronic circuits and more;

- Easy to automate: the physical structure of laser welding is simpler than that of TIG and MIG, which facilitates the development and use of automated welding.

Laser cleaning has been used since the 1960s, but it has been popularized for industrial rust removal in the last decade. Non-contact laser cleaning is more efficient and sustainable than ultrasonic or detergent cleaning. Pulsed laser cleaners have become popular as MOPA lasers have become more affordable over the years, offering finer cleaning quality and a wider range of applications than CW cleaners.

- Efficiency: the high-energy laser beam vaporizes contaminants in a very short time with minimal damage to the workpiece.

- Non-consumable: laser cleaning can be operated without detergents or catalysts, a significant savings for high-volume industrial metal derusting.

- Non-contact: laser beam can remove rust, oxides, oil, grease, paint and coating at a distance, therefore suitable to clean hard-to-touch workpiece such as injection mold.

Explore Our Machines For Metal Application

Types of Metals Suitable for Our Marking Machines

Steel

There are a wide range of steels commonly used in industry, which are mainly categorized into carbon steel and alloy steel. Carbon steel is the most widely used because of its high yield and low price, while alloy steel is based on carbon steel to improve toughness, strength, corrosion resistance or wear resistance. Due to its high yield, strength, toughness and ease of processing, steel has irreplaceable applications in all industries. For steel, we offer advanced laser marking, engraving, welding and cleaning solutions in addition to the oldest and most reliable needle marking systems.

Aluminum

Due to its active chemical properties, aluminium is usually processed and used in the form of aluminium alloys. Due to its low density, moderate strength, high corrosion resistance, and ease of machining, aluminum alloys are widely used in engineering or product structures and components that require lightweight or corrosion resistant construction. In addition, the aesthetics of anodic oxidation or electrophoresis processes make aluminum alloys more common on the surfaces of products.

Copper

As the metal with the longest history of human use, whether it is copper, brass, bronze or other copper alloys are still widely used. Copper has excellent electrical and thermal conductivity, is easy to fabricate and is highly corrosion resistant. In addition to electrical systems and cables that need to be insulated, copper is also used in a wide range of applications such as metal parts, piping and connectors, chemical and medical containers, home finishing materials, heat dissipation systems, works of art and many more. For copper, we offer advanced laser marking, engraving, welding and cleaning solutions in addition to the oldest and most reliable needle marking systems.

Zinc

Zinc and zinc alloys have a low density, a low melting point, are easy and inexpensive to machine, have some corrosion and abrasion resistance, and are often galvanized on steel surfaces. In the construction, engineering and machinery industries, steel surfaces and components are often galvanized to protect them from rust, while various types of zinc alloys are used in the engine, sanitary and smart lock industries. For zinc alloy or galvanized, we offer advanced laser marking, engraving, welding and cleaning solutions in addition to the oldest and most reliable needle marking systems.

Titanium

As the newest metal to be used on a large scale, titanium and titanium alloys have the highest specific strength (ratio of tensile strength to density), high and low temperature resistance, extremely low heat distortion, and strong corrosion resistance of any metal. Pure titanium is also extremely biocompatible and is therefore used in a wide range of applications in the aerospace, medical, chemical, automotive, shipbuilding and marine industries. For titanium, we offer advanced laser marking, engraving, welding and cleaning solutions in addition to the oldest and most reliable needle marking systems.

Gold

Gold’s excellent oxidation resistance and chemical stability have made it one of the most important currencies and investments in human history, and it has been used extensively for jewelry and architectural decoration. In addition, gold’s excellent ductility and ease of fabrication have made it useful in microelectronic circuits, aerospace and medical devices. For gold and K-gold, we offer advanced laser marking, engraving and welding solutions in addition to the oldest and most reliable needle marking systems.

Silver

Silver has a certain bactericidal ability and high reflectivity, since ancient times has been used in jewelry, mirrors, high quality tableware and medical equipment. In modern times, silver has been used in electronic circuits, electrical and precision instruments because of its best electrical and thermal conductivity among all metals and its high degree of application in electronic circuits, electrical and precision instruments. For silver, we offer advanced laser marking, engraving and welding solutions in addition to the oldest and most reliable needle marking systems.

Platinum

Platinum and platinum group metals belong to the excessive metal, although with stable chemical properties and oxidation corrosion resistance, and good biocompatibility, but more commonly used as reaction catalysts or as a modification of other materials additives, at present the most common individual application is platinum jewelry. For platinum, we offer advanced laser marking, engraving and welding solutions in addition to the oldest and most reliable needle marking systems.

Want an un art handing video demonstration on specialized material? Looking for a solution to your specialized environment or automatic process demand?