Nameplate Marking Machine: What You Need to Know

Nameplate marking machines are an important tool for identifying and tracking products, assets, and equipment across a wide range of industries. These machines create durable, high-quality marks on nameplates that provide important information such as serial numbers, model numbers, manufacturer details, and safety instructions. Two types of engraving systems are in vogue today, dot peen marking and laser engraving.

Understanding the importance of nameplate marking and the different methods available can help businesses choose the machine that best suits their needs.

Why Nameplate Marking is needed?

Nameplate marking is a vital process across numerous industries, serving several important functions.

- Primarily, it offers clear identification of products, components, or assets, which is essential for maintaining traceability and preventing errors. By clearly marking items, companies can avoid confusion, especially when dealing with large inventories or complex machinery.

- Additionally, nameplates provide specific product information, such as model numbers, serial numbers, or manufacturing dates. This detailed information is critical for various purposes, including quality control, warranty claims, and customer service. For instance, if a product needs servicing or replacement, the information on the nameplate can help ensure the correct parts are used, maintaining the integrity and safety of the product.

- Furthermore, nameplate marking helps in regulatory compliance by ensuring that all necessary product information is clearly displayed, aiding both manufacturers and end-users in maintaining proper documentation and operational standards.

Types of Nameplate Marking Methods

When it comes to marking nameplates, there are several methods available, each suited to different applications and materials. Two of the most widely used methods are dot peen marking and laser marking.

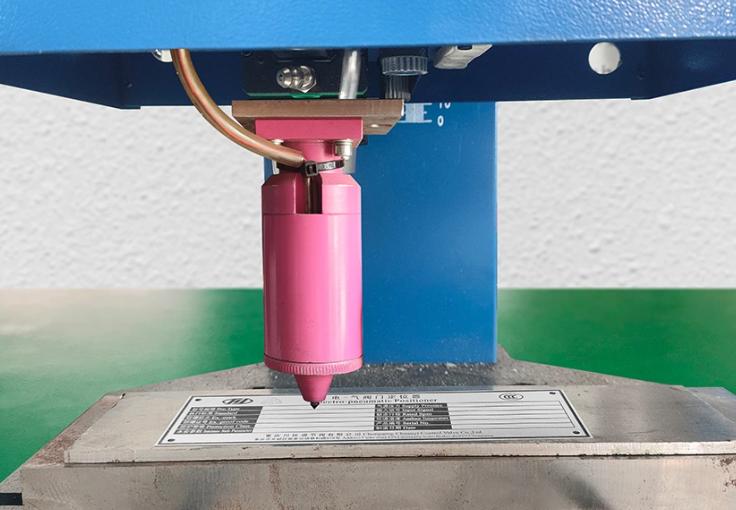

Dot Peen Marking

Dot peen marking, also known as pin marking, is a direct impact marking process that creates permanent marks on a nameplate using a hard-tipped stylus. The stylus is pneumatically or electromechanically driven to strike the surface of the material in a series of closely spaced dots, forming characters, numbers, or images.

Advantages of Dot Peen Marking:

- Durability: Dot peen marking produces deep, indented marks that are resistant to wear, corrosion, and environmental conditions, making it ideal for harsh environments and applications where longevity is critical.

- Versatility: This method can be used on a wide range of materials, including metals, plastics, and even hardened steel, without damaging the integrity of the material.

- Cost-Effectiveness: Dot peen marking machines are generally more affordable than laser marking systems, making them a budget-friendly option for many industries. They also have lower maintenance costs due to their simple mechanical operation.

Dot peen marking widely used in the automotive, aerospace, and manufacturing industries for marking parts and components with serial numbers, barcodes, logos, and other identifying information. It is especially useful for parts that undergo heavy use or are exposed to extreme conditions.

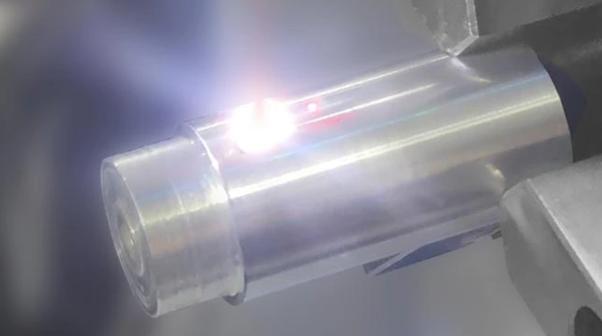

Laser Marking

Laser marking is a more advanced method that uses a focused laser beam to etch or engrave markings onto the surface of a nameplate. The laser precisely removes material or changes its color, creating sharp, detailed marks.

Advantages of Laser marking:

- High Precision: Laser marking provides exceptionally fine detail, making it ideal for small or intricate designs, such as logos, barcodes, or serial numbers, where clarity is essential.

- Non-Contact Process: Since the laser doesn’t physically touch the nameplate, there’s no risk of damaging the material during the marking process, which is particularly beneficial for delicate or sensitive components.

- Speed and Efficiency: Laser marking is a fast process, capable of producing high-quality marks in a short amount of time, making it suitable for high-volume production environments.

Laser marking is widely used in industries like electronics, medical devices, and jewelry, where precise, detailed markings are necessary, and the aesthetic appearance of the mark is important.

Both dot peen and laser marking methods have their unique advantages and are suited to different applications. The choice between these methods depends on factors such as the type of material, the required mark durability, the precision needed, and the production volume. By selecting the appropriate marking method, businesses can ensure that their nameplates meet all their identification, compliance, and branding needs.

What Industry Use Nameplate Marking?

In the aspects of real-world applications, many industries are using nameplate marking techniques:

- Automotive Industry: In the automotive sector, nameplate marking is essential for identifying parts, engines, and other components. Markings such as VIN numbers, serial numbers, and manufacturing details are used to ensure proper assembly, maintenance, and compliance with safety regulations. Durable markings also facilitate recall management and warranty claims, enhancing customer safety and satisfaction.

- Aerospace Industry: The aerospace industry requires stringent tracking and identification of parts and components due to strict safety and regulatory standards. Nameplate markings on aircraft parts, such as engines and avionics, provide essential information about the manufacturer, serial number, and maintenance history, ensuring safety and traceability throughout the aircraft’s lifecycle.

- Medical Device Industry: Medical devices often require permanent markings for identification, traceability, and compliance with health regulations. Nameplates on medical devices display important information such as lot numbers, expiration dates, and usage instructions, which are crucial for patient safety and effective device management.

- Electronics Industry: In electronics, nameplate marking is used to identify circuit boards, components, and connectors. This facilitates quality control, inventory management, and compliance with regulatory standards, ensuring that each component can be traced back to its origin.

- Manufacturing Industry: Across various manufacturing sectors, nameplate marking is used to label machinery, tools, and equipment with important information such as operating instructions, safety warnings, and serial numbers. This helps in maintenance management, and equipment tracking, and ensures that safety protocols are followed.

These industries utilize nameplate marking to enhance operational efficiency, ensure regulatory compliance, maintain safety standards, and improve overall product quality. By providing clear, permanent identification, nameplate markings support critical processes such as inventory control, maintenance, and safety management.

Common Materials Used to Mark

Nameplate marking machines are capable of processing a variety of materials, ensuring versatility and adaptability across different industries. Here are some of the most common materials used for nameplate marking:

- Stainless steel nameplate

Stainless steel nameplates are often used on industrial equipment and mechanical equipment because of their corrosion resistance and high temperature resistance. Stainless steel is hard and durable, not easy to rust, and is suitable for humid or rainy environments, such as kitchen equipment, ships, chemical equipment, etc. Stainless steel nameplates usually use 201, 304, 410 and other models, among which 304 stainless steel is widely used in consumer electronics because it is resistant to corrosion by various media.

- Aluminum alloy nameplate

Aluminum alloy nameplates are lightweight and have good corrosion resistance, suitable for outdoor use. Aluminum alloy material makes the nameplate light, easy to install, and easy to process into various shapes. Aluminum alloy nameplates are often used in vehicles, aerospace and other fields, and can also be used for interior decoration, such as furniture, office supplies, etc.

- Copper nameplate

Copper nameplates have a unique metallic luster and are often used in occasions that require decorative or cultural traditions. Copper is wear-resistant and weather-resistant, and is suitable for long-term outdoor use. Copper nameplates are often used for medals, commemorative plaques, etc., and their golden color gives people a noble feeling.

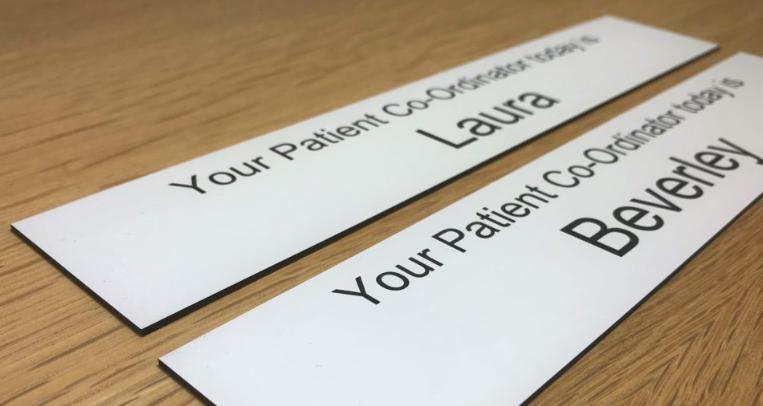

- Non-metallic materials such as PVC and acrylic

Non-metallic material nameplates such as PVC and acrylic are light and colorful, suitable for indoor signs and billboards. These materials are easy to process, relatively low in cost, and can be printed with rich patterns and information.

By understanding the properties and characteristics of these materials, businesses can select the most appropriate material for their specific nameplate marking needs.

Top Brand to Consider When Choosing Nameplate Marking Machine

When selecting a nameplate marking machine, it’s essential to consider reputable brands known for quality, reliability, and customer support. Here are some top brands to consider:

- Zixu: Zixu is a source factory in the nameplate marking machine market, known for its innovative technology and competitive pricing. Zixu machines offer a range of marking options, including laser and dot peen systems.

- Gravotech: A leader in the engraving and marking industry, Gravotech offers a range of dot peen and laser marking machines suitable for various applications.

- Telesis: Known for its robust dot peen and laser marking systems, Telesis machines are widely used in automotive, aerospace, and industrial manufacturing.

- SIC Marking: SIC Marking specializes in dot peen, laser, and scribing machines, offering durable and precise solutions for metal and plastic marking.

The Last You Need to Know

In general, nameplate marking machines are vital tools for businesses. You can choose the best nameplate marking machine for your specific needs.

If you want to know more, you can contact us for detailed information.

Our expert team will lead you to select the best nameplate marking machine according to your specific needs and budget.

Recommended Products