Optimizing Marking Depth: A Guide for Pneumatic Marking Machines

Pneumatic marking machines are versatile tools that utilize compressed air to create permanent markings on a wide range of materials. From simple text and numbers to complex logos and barcodes, these machines offer precision and efficiency in industrial marking applications. However, achieving the desired marking depth can be influenced by several factors. This guide delves into the key aspects of optimizing marking depth in pneumatic marking machines.

What is a Pneumatic Marking Machine?

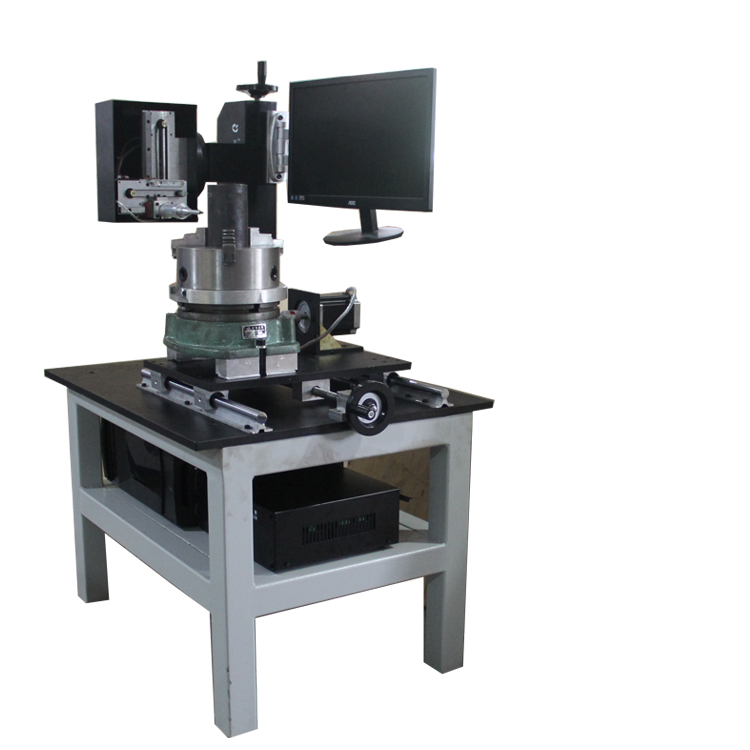

A pneumatic marking machine is a device that utilizes compressed air as its power source and employs computer control to drive a marking pin against a workpiece, creating a clear and deep mark. By precisely controlling the movement of the marking pin and utilizing the impact force of compressed air, this machine can imprint various information such as serial numbers, model numbers, and production dates onto workpieces.

Pneumatic marking machines find extensive applications in manufacturing industries, including automotive parts, machinery hardware, and instrumentation. They play a crucial role in product traceability and management by providing clear and permanent markings on workpieces.

How Does a Pneumatic Marking Machine Work?

A pneumatic marking machine is a non-contact marking device commonly used in industrial settings. Its operation is primarily driven by a compressed air system. The pneumatic marking machine involves a series of interconnected components, including:

- Compressed Air Supply: A compressed air source provides the necessary energy for the marking process.

- Air Regulator: The air regulator controls the pressure of the compressed air, ensuring consistent and precise marking.

- Solenoid Valve: The solenoid valve, activated by an electrical signal, controls the flow of compressed air to the marking pin.

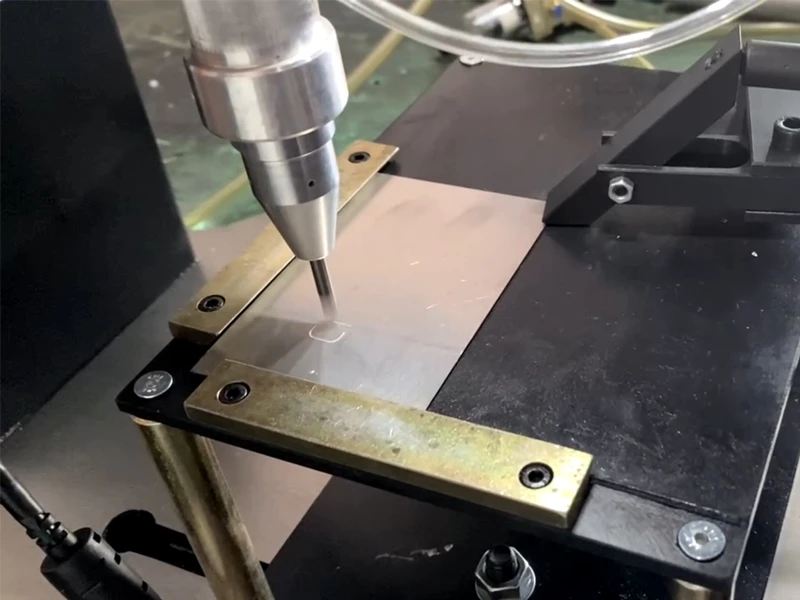

- Marking Pin: The marking pin, made of a hard and durable material, is the component that directly contacts the workpiece and creates the mark.

When the solenoid valve is triggered, a burst of compressed air is released, propelling the marking pin against the workpiece. The impact force of the pin creates a small indentation in the material, forming the desired mark.

How to Increase Marking Depth in a Pneumatic Marking Machine?

For some products that require deeper engraving depth, how can we use pneumatic marking machines to achieve deeper engraving? The following are several main considerations:

Adjusting Air Pressure

Pneumatic marking machines rely on compressed air to work. The air pressure is crucial for the quality of the marks. If the pressure is too low, the marks might be shallow and fade easily. On the other hand, excessive pressure can damage the product’s surface by making the marks too deep. To get the best results, it’s important to maintain a stable and appropriate air pressure that matches the material being marked.

- Increasing Air Pressure: By increasing the air pressure, you can enhance the impact force of the marking pin, leading to deeper markings. However, excessive pressure can damage both the machine and the workpiece.

- Matching Pressure to Material: Different materials exhibit varying degrees of hardness. Softer materials generally require lower air pressure, while harder materials necessitate higher pressure.

Adjusting the Marking Needle

Since marking needles are considered consumables, pneumatic marking machine manufacturers often include a few with the machine as a standard accessory. These needles are typically designed to meet the needs of most users who prioritize marking clarity over depth. Common core diameters for marking needles available on the market include 2mm, 3mm, and 4mm. Generally speaking, a larger core diameter results in a deeper mark.

- Selecting the Right Needle: The choice of marking needle material and tip shape significantly impacts marking depth. Harder pin materials, like carbide, are suitable for harder materials.

- Optimizing Pin Depth: The distance between the marking needle and the workpiece influences the impact force. Adjusting this distance can help achieve the desired marking depth.

Adjusting Marking Speed

- Decreasing Speed: It is generally observed that a slower marking speed results in a greater marking depth. This phenomenon can be attributed to the increased dwell time of the marking needle on the workpiece surface at lower speeds. With more time for energy transfer, a deeper engraving is produced.

Optimizing the Marking Program

- Reducing Fill Spacing: Decreasing the spacing between individual dots in the marking pattern can increase the overall marking area and depth.

- Increasing Repetition: Repeating the marking process multiple times over the same area can deepen the mark.

Inspecting Equipment Condition

- Checking Air Supply: Ensure that the air supply is clean and free of contaminants.

- Inspecting Solenoid Valve: Verify the proper functioning of the solenoid valve.

- Checking Spring Tension: Inspect the spring tension for wear or damage.

What Deep Pneumatic Marking Machine Do You Need?

To ensure you choose a high-performance pneumatic marking machine that meets your specific needs, consider the following tips:

Clarify Your Needs and Budget:

- Determine key parameters: Based on your production requirements, specify the required power, marking speed, and marking depth of the marking machine.

- Set a reasonable budget: Consider the cost-effectiveness of the equipment within your budget.

Understand Product Performance:

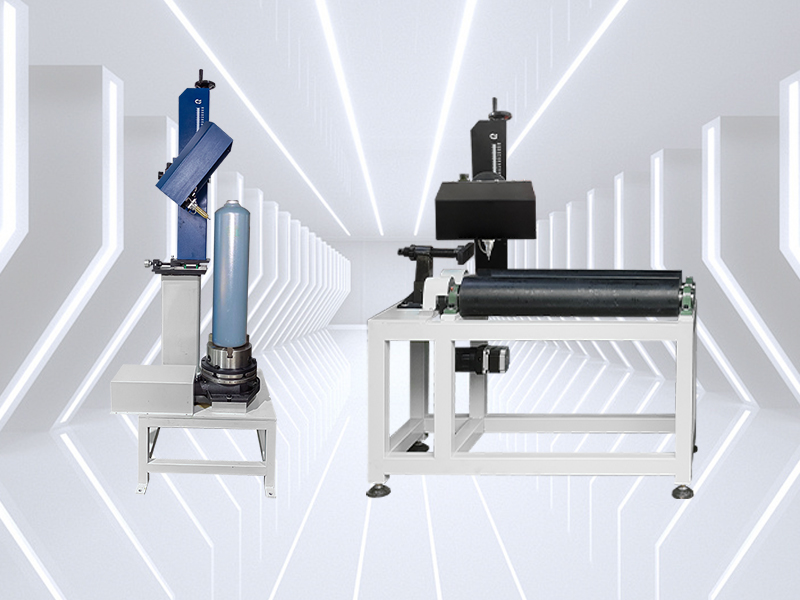

- Marking effect: The pneumatic marking machine should be able to produce clear and accurate marks on various materials, such as metals, plastics, and rubber.

- Marking speed: Pneumatic marking machines typically offer high marking speeds to significantly improve work efficiency.

- Stability and lifespan: Choose equipment that uses imported components and has high reliability and a long lifespan.

Evaluate Company Strength:

- Conduct thorough market research: Learn about the company strength and technical level of different brands and suppliers.

- Understand after-sales service policies: This includes warranty periods and repair response times. Choose a supplier that provides comprehensive after-sales service to ensure timely technical support and repair services during use.

Zixu Machine offers advanced pneumatic marking machines designed to enhance your production processes. By improving efficiency and reducing costs, our machines deliver a significant return on investment.

Contact us today to explore how we can meet your specific needs.

Recommended Products