Pneumatic Marking Machines in Custom Part Marking

Need to permanently mark parts? Pneumatic marking machines are your go-to solution for precise, durable part identification. These machines utilize compressed air to deliver powerful, controlled impacts that create lasting marks on a diverse range of materials, from sturdy metals to delicate plastics.

What Are Pneumatic Marking Machines?

Pneumatic marking machines are tools that use compressed air to power a marking mechanism, typically a pin or stylus, to apply permanent marks to various materials. The marking tool is driven by the force of compressed air, allowing it to strike the surface of a part with precision and consistency. These machines are highly reliable and are widely used for marking a range of materials including metals, plastics, ceramics, and composites.

Key Features of Pneumatic Marking Machines

- Compressed Air Operation: Pneumatic marking machines use compressed air to power the marking pin or stylus, offering greater energy efficiency and requiring less electrical input compared to electrically driven systems.

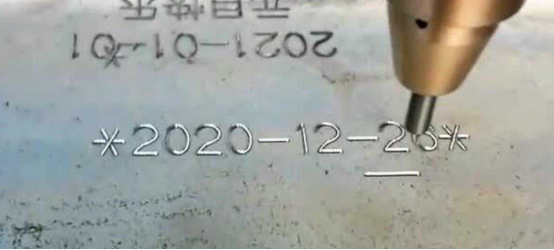

- Precision Marking: These machines deliver precise, clear markings, making them ideal for applications demanding high accuracy, such as engraving serial numbers, barcodes, or logos.

- Durability: The permanent marks created by pneumatic machines are highly resistant to wear and corrosion, ensuring long-term traceability even under harsh conditions.

- Versatility: Capable of marking a wide range of materials, from soft plastics to tough metals, these machines are widely used across industries like automotive, aerospace, medical devices, and electronics.

- Minimal Maintenance: With fewer moving parts, pneumatic marking systems are simpler in design and require less maintenance than other types of marking machines.

Overall, pneumatic marking machines offer an efficient and flexible solution for custom part marking, ensuring high-quality results with minimal operational costs.

Common Types of Pneumatic Marking Machines

Pneumatic marking machines come in various types, each tailored to specific marking requirements. Understanding these types will help you identify which machine best suits your needs. Below, we dive deeper into the most common types:

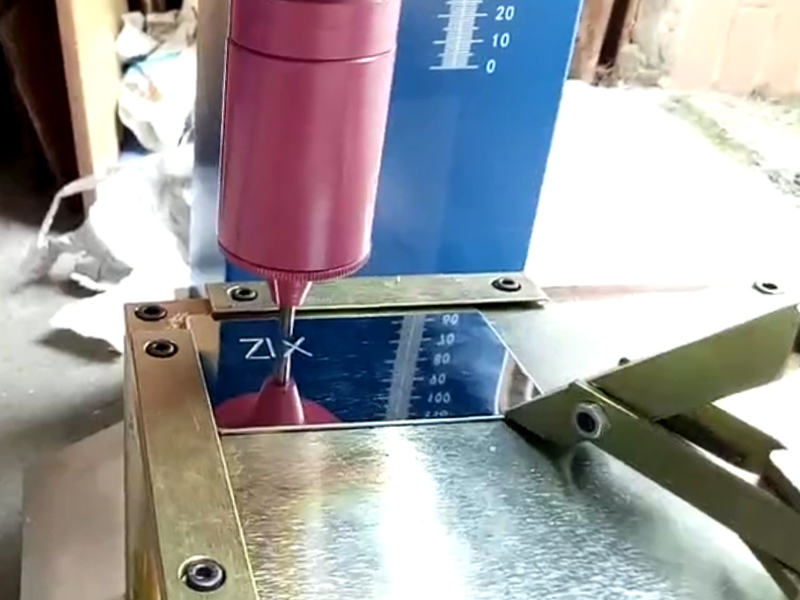

Pneumatic Dot Peen Marking Machines

Pneumatic Dot peen marking machines are among the most commonly used pneumatic marking systems, known for their ability to create highly durable and precise marks. These machines work by using a small pin or stylus that rapidly strikes the surface of the material in a series of tiny, closely spaced dots. By arranging these dots in a specific pattern, the machine can create readable text, numbers, logos, barcodes, QR codes, and even more complex designs like Data Matrix codes.

- Typical Applications:

Dot peen marking machines are widely used in industries where traceability, part identification, and quality control are critical. Some common applications include:

- Automotive Industry: Used to mark parts like engine blocks, gears, and chassis components with serial numbers, part IDs, and manufacturer logos.

- Aerospace: Ideal for marking critical components such as turbine blades, aircraft frames, and fasteners with serial numbers and safety codes.

- Heavy Manufacturing: Frequently used in metalworking for marking large, heavy-duty components like valves, shafts, and heavy machinery parts.

- Customizable Features:

Many modern dot peen machines offer advanced software for easy integration with production systems. Features like automatic depth adjustment, adjustable marking speeds, and variable dot size help tailor the marking to different materials and part sizes. Some machines even offer rotary attachments for marking cylindrical parts with consistent precision.

Dot peen marking machines stand out for their ability to create robust and high-quality marks on a variety of surfaces. Whether you’re marking industrial components, automotive parts, or delicate electronic devices, these machines are an excellent choice for permanent, high-visibility markings that can withstand the test of time.

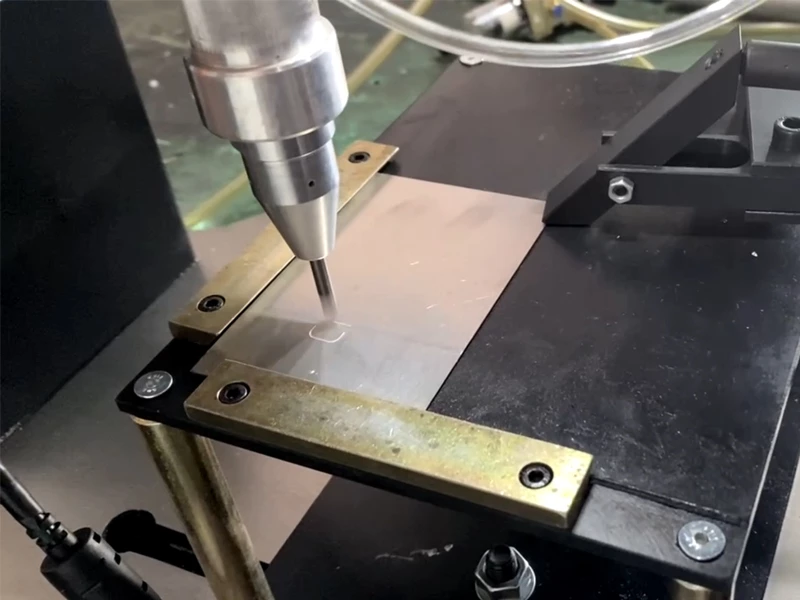

Scribe Marking Machines

Scribe marking machines work differently from dot peen systems. Instead of striking the surface with rapid dots, these machines use a sharp stylus to carve smooth, continuous lines into the material. The stylus, driven by pneumatic force, glides across the surface to produce permanent and precise markings.

Scribe marking machines work differently from dot peen systems. Instead of striking the surface with rapid dots, these machines use a sharp stylus to carve smooth, continuous lines into the material. The stylus, driven by pneumatic force, glides across the surface to produce permanent and precise markings.

1. Advantages of Scribe Marking Machine:

- Produces highly legible, refined markings that are free of the roughness associated with dot peen marks.

- Operates quietly with minimal vibration, making it suitable for environments where noise control is important.

- The smooth engraving process minimizes stress on the material, making it ideal for delicate parts or those requiring tight tolerances.

2. Typical Applications:

Scribe machines are widely used in industries like electronics, medical devices, and luxury goods, where aesthetics and precision are crucial. For instance, they are often used to engrave logos, serial numbers, or product codes on components like surgical tools, electronic panels, and fine jewelry.

3. Customization Options:

Many scribe marking systems offer adjustable settings for line depth, thickness, and speed, allowing for flexibility in creating detailed designs or intricate branding. Whether used for marking high-value products or achieving a polished, professional appearance, scribe machines provide both accuracy and sophistication.

This blend of precision, durability, and a refined finish makes scribe marking machines ideal for applications where aesthetics are as important as functionality.

Applications of Pneumatic Marking Machines in Custom Part Marking

Pneumatic marking machines are indispensable tools in various industries for precise and durable part marking. Here are some of their key applications:

- Automotive: Marking engine blocks, transmission housings, and other components with part numbers, production dates, and manufacturer logos to ensure traceability and quality control.

- Aerospace: Marking aircraft parts, tools, and equipment with serial numbers, maintenance records, and safety information to comply with stringent industry regulations and standards.

- Medical Device Manufacturing: Marking surgical instruments, implants, and medical devices with lot numbers, expiration dates, and regulatory compliance markings to guarantee patient safety and regulatory adherence.

- Electronics Manufacturing: Marking circuit boards, electronic components, and enclosures with part numbers, manufacturer codes, and traceability information to facilitate inventory management and quality assurance.

- General Manufacturing: Marking a wide range of products, including industrial machinery, tools, and consumer goods, with product identification, batch numbers, and other essential information.

These diverse applications demonstrate the versatility and importance of pneumatic marking machines in creating permanent, reliable marks in industries where precision and durability are critical.

How to Choose a Suitable Pneumatic Marking Machine

Choosing the right pneumatic marking machine is essential for ensuring efficient and accurate part marking. Here are the key factors to consider when selecting a machine for your needs:

1. Material Compatibility

Ensure the machine is suitable for the material you’re marking. Some machines are designed for softer materials like plastic, while others can handle tougher metals. Make sure the marking tool can effectively mark the specific material of your parts.

2. Marking Depth and Precision

Consider the type of mark you need. If you require deep, permanent marks (like serial numbers on metal parts), a dot peen machine is ideal. For fine, shallow engravings (such as in electronics or medical devices), a scribe marking machine might be better.

3. Production Speed

If you’re working with high volumes, choose a machine that can keep up with your throughput needs. Some machines prioritize speed, while others are better suited for detailed, slower marking. Make sure the machine can handle the speed of your production process without sacrificing quality.

4. Size and Portability

Think about how much space you have and whether you need the machine to be movable. Some pneumatic marking machines are compact and portable, while others are larger and better suited for fixed setups in a dedicated workspace.

By focusing on these key points—material compatibility, marking depth and precision, speed, and size—you can ensure you select the pneumatic marking machine that best fits your marking requirements.

Conclusion

Pneumatic marking machines offer a reliable and versatile solution for custom part marking in various industries. By understanding the different types of machines and their applications, manufacturers can select the most suitable equipment to meet their specific marking needs. For any need of pneumatic marking machines, you can contact our service team for more information.

Recommended Products