Portable vs. Stationary Flange Marking Machines: Which to Choose?

Flange marking machines play a crucial role in the industrial landscape, particularly in sectors like manufacturing, construction, and metalworking. These machines are specifically designed to mark critical information on flanges, such as identification numbers, material types, and other essential details that facilitate proper installation, traceability, and quality control.

Role of Flange Marking Machines

Flange marking machines play a crucial role in ensuring that flanges are accurately labeled according to industry standards and regulations. This precision is essential, as it facilitates quick identification during installation, significantly reducing the risk of errors that can lead to costly delays or safety hazards. By enabling faster assembly processes, these machines improve overall operational efficiency, allowing teams to focus on other critical tasks.

Moreover, proper marking is vital for effective maintenance and inventory management, helping organizations track their components with ease. Clear labeling ensures that every part can be quickly located and serviced, which is particularly important in industries where downtime can be expensive.

Whether employed in large-scale production facilities or smaller batch operations, flange marking machines enhance productivity and contribute to a safer workplace environment. Their ability to streamline workflows not only boosts efficiency but also promotes compliance with safety standards, ultimately leading to better project outcomes and reduced liability for organizations.

Types of Flange Marking Machines

Flange marking machines come in two primary types: portable and stationary. Each type is designed to meet specific industrial needs based on the environment, volume of work, and marking precision required. Understanding the features and applications of these machines can help you select the best option for your operational requirements.

Portable Flange Marking Machines

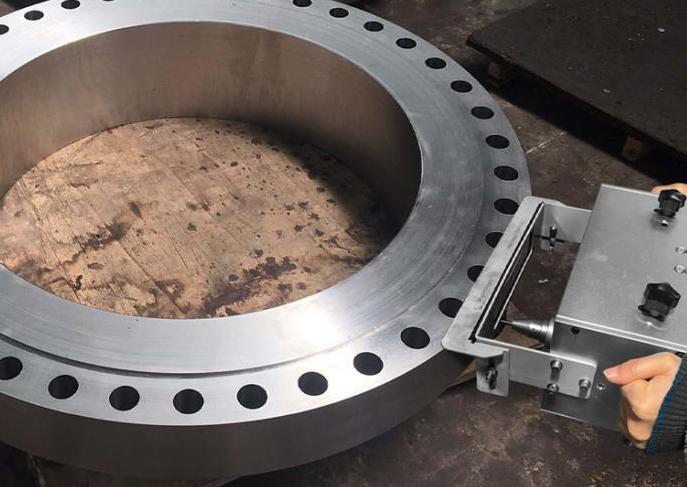

Portable flange marking machines are designed with mobility in mind, making them ideal for on-site use. These machines are typically compact, lightweight, and easy to transport, allowing workers to mark flanges in remote or dynamic environments. Portable machines are particularly useful in industries like construction, oil and gas, or maintenance services, where marking needs to occur directly on the job site.

They offer versatility in terms of flange sizes and materials, and their ease of use allows for quick setup and marking in diverse conditions.

Key Features of Portable Flange Marking Machines:

- Mobility: Easily transported between job sites or departments.

- Ease of Use: Minimal setup time and user-friendly operation.

- Flexibility: Can mark a variety of flange sizes and materials.

- Space-saving: Suitable for environments with limited space or temporary setups.

While portable machines are convenient, they are generally designed for smaller-scale operations and may not offer the same level of automation or precision as their stationary counterparts.

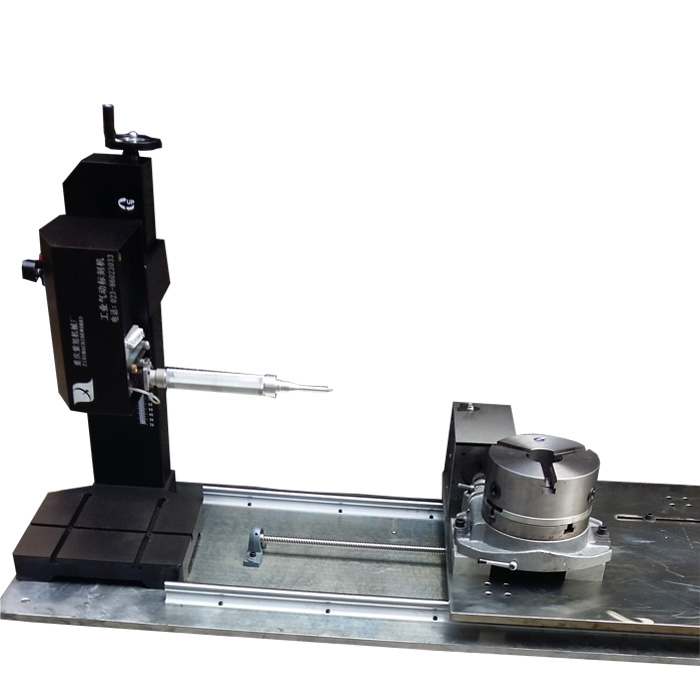

Stationary Flange Marking Machines

Stationary flange marking machines, on the other hand, are designed for use in fixed, high-production environments like manufacturing plants. These machines are often integrated into the production line, enabling rapid, continuous marking of large volumes of flanges with minimal operator intervention. Stationary machines are typically equipped with more advanced technology, such as CNC systems or laser marking, allowing them to produce precise, detailed marks on flanges.

Due to their fixed nature, stationary machines are best suited for businesses with consistent, high-volume production needs. They offer unmatched efficiency for long production runs, significantly reducing marking time and increasing output.

Advantages of Stationary Flange Marking Machines:

- High Efficiency: Optimized for continuous, high-volume production.

- Advanced Technology: Often includes CNC or laser marking for precise, detailed work.

- Durability: Built for long-term use in demanding production environments.

- Automation: Can be integrated with production lines for seamless operation.

- Consistency: Ensures uniformity and accuracy in marking, even over long runs.

By understanding the strengths of each type, businesses can choose the right machine to enhance their operational efficiency, depending on their specific production requirements, budget, and location constraints.

Key Differences Between Portable and Stationary Flange Marking Machines

| Feature | Portable Flange Marking Machine | Stationary Flange Marking Machine |

| Portability | Highly portable, easily moved to different locations. Ideal for on-site work or small workshops. | Not portable, requires a fixed installation. Suitable for large-scale production facilities. |

| Size | Smaller and lighter, suitable for confined spaces. | Larger and heavier, often requires a dedicated workspace. |

| Features | Basic marking capabilities, such as simple text and numbers. | Advanced features like logo marking, barcoding, and serial number generation. Can accommodate complex marking patterns. |

| Production Volume | Suitable for low to medium production volumes, or for marking individual flanges. | Ideal for high-volume production, providing efficient and consistent marking. |

| Cost | Generally more affordable due to its simpler design and features. | Typically more expensive due to its advanced capabilities and larger size. |

| Customization | Limited customization options. | Offers more customization options, such as different marking heads and fonts. Can be tailored to specific marking requirements. |

| Maintenance | Easier to maintain due to its simpler design. | May require more complex maintenance procedures and specialized technicians. |

| Power Source | Typically powered by batteries or a small generator. | Often powered by a dedicated electrical outlet. |

We can summarize from this table, the choice between a portable and stationary flange marking machine depends on several factors, including production volume, required features, budget, and the specific needs of your application. Portable machines offer flexibility and affordability, while stationary machines provide higher levels of productivity and customization. By carefully considering these factors, you can select the most suitable machine for your marking requirements.

Factors to Consider When Choosing these Two

When deciding between portable and stationary flange marking machines, several factors should guide your decision:

- Application Volume: Consider your production needs. For low to moderate volumes or on-site marking, a portable machine offers flexibility. If you handle high-volume production, a stationary machine provides better efficiency and speed.

- Work Environment: Assess your space and operational setting. Portable machines excel in tight spaces or dynamic environments like construction sites, while stationary machines are ideal for dedicated, large-scale facilities.

- Budget: Portable machines generally require a lower upfront investment, making them attractive for smaller operations. However, stationary machines may offer long-term cost savings due to their higher efficiency for large-scale production.

- Marking Complexity: If your marking requirements involve detailed or intricate designs, stationary machines with advanced technology, like CNC or laser marking, may be more suitable.

- Future Needs: Consider growth potential. If you expect increased demand or more complex applications, a stationary machine might offer better scalability.

Want to Purchase a Flange Marking Machine?

If you’re considering purchasing a flange marking machine, it’s essential to research different models and brands to find the best option for your needs.

Look for reputable suppliers with experience in the industry. Consider factors like machine quality, warranty, and after-sales support. Zixu must be your first choice for our years of experience and expert techniques. Feel free to contact us if you have any need.

Recommended Products