Advantages of Laser Marking in the PCB Industry

Printed circuit boards (PCBs) are the backbone of modern electronics, found in everything from smartphones to industrial machinery. As technology advances, the complexity and miniaturization of PCBs increase, demanding precise and efficient manufacturing processes. Лазерная маркировка has emerged as a leading technology for marking PCBs, offering numerous advantages over traditional methods.

This article explores the working principle of PCB laser marking machines, highlights the unique benefits of this technology, discusses the applications of UV and CO2 lasers in the PCB industry, and takes you to experience the revolutionary changes in the field of PCB manufacturing.

Working Principle of PCB Laser Marking Machines

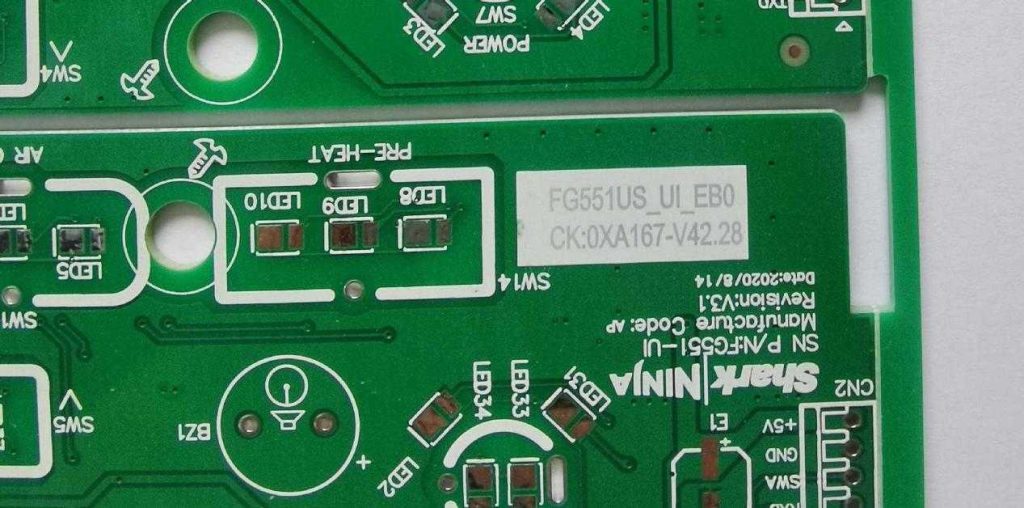

PCB laser marking machines utilize a focused beam of light to create permanent marks on the surface of a PCB. The process involves directing a laser beam, typically generated by a CO2 or UV laser source, through a series of optical components, including mirrors and lenses. These components precisely control the laser beam’s position and intensity, allowing for the creation of intricate patterns, text, and barcodes.

When the focused laser beam interacts with the PCB material, it causes localized heating, ablation, or a change in the material’s properties, resulting in a visible mark. The type of mark produced depends on the laser parameters (power, frequency, speed) and the PCB substrate material. Modern laser marking systems are often computer-controlled, enabling automated and highly accurate marking processes.

Unique Advantages of Laser PCB Marking

Compared to traditional printing technologies, laser PCB marking offers a range of unique advantages, making it the preferred method in the electronics manufacturing industry.

| Характеристика | Labeling | Inkjet Printing | Лазерная маркировка |

| Line Width | Millimeter Level | Millimeter Level | Micrometer Level |

| Minimum Font Size | 2mm | 2mm | 100um |

| Minimum QR Code | 5*5mm | 4*4mm | 0.7*0.7mm |

| PCB Space Requirement | Above 6*6mm | Above 4.5*4.5mm | Above 1.2*1.2mm |

| Consumables | Ink, Labels | Ink | None |

| Consumable Cost (24H) | 300,000/year | 300,000/year | 0 |

| Долговечность | Easy to Fall Off, Damaged | Easy to Fall Off, Damaged | Surface Engraving, Never Lost |

High Precision and Resolution

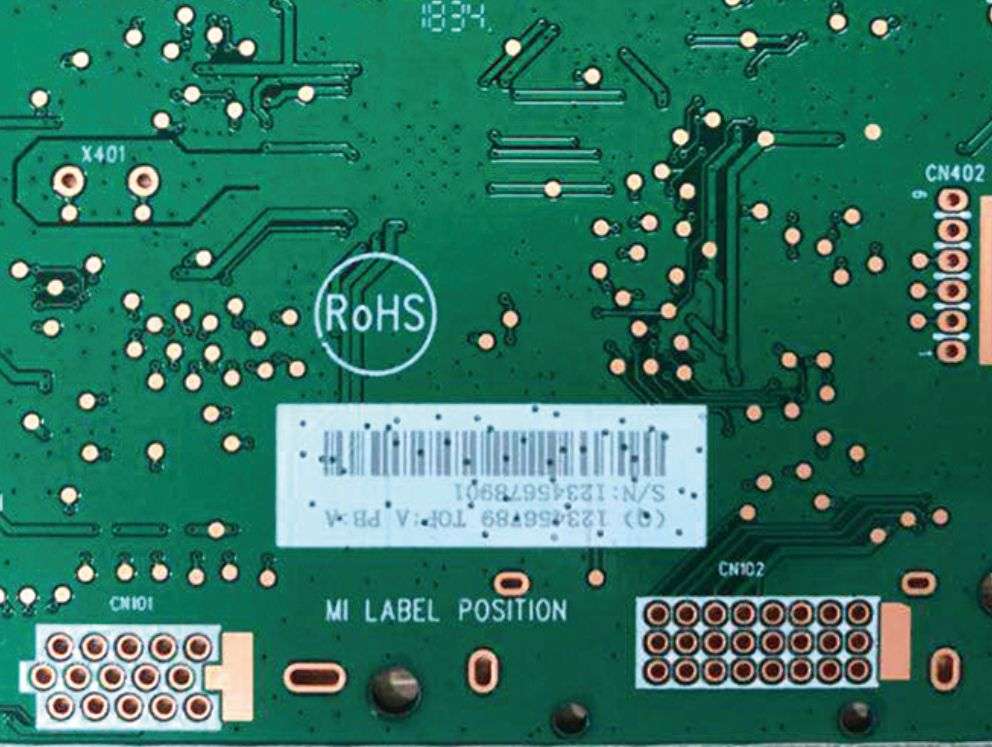

Laser marking offers unparalleled precision and resolution, enabling the creation of extremely fine and detailed marks. This is crucial for marking small components, QR codes, and other intricate designs on PCBs, especially as component sizes shrink. The focused laser beam can produce marks with resolutions down to the micrometer level, ensuring clear and legible markings.

Бесконтактная обработка

Unlike traditional marking methods that involve physical contact with the PCB, laser marking is a non-contact process. This eliminates the risk of mechanical stress or damage to the delicate components and circuitry on the PCB. Non-contact processing also allows for marking on uneven or curved surfaces.

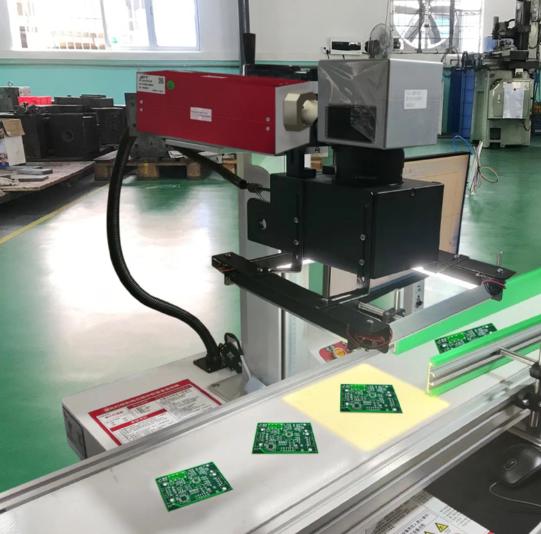

Increased Production Efficiency

Laser marking is a high-speed process, significantly increasing production efficiency compared to other methods. The ability to create marks quickly and accurately reduces production time and throughput, leading to cost savings and faster turnaround times. Automation further enhances the efficiency of laser marking systems.

High Flexibility

Laser marking is highly flexible and adaptable to different marking requirements. The software-controlled system allows for easy changes in marking content, including text, logos, barcodes, and serial numbers. This flexibility makes laser marking suitable for both high-volume production and customized or low-volume applications.

Постоянная маркировка

Laser marks are permanent and highly durable. They are resistant to abrasion, chemicals, and high temperatures, ensuring that the markings remain legible and intact throughout the lifespan of the PCB. This is essential for traceability, identification, and quality control purposes.

Environmentally Friendly with No Consumables

Laser marking is an environmentally friendly process that does not require any consumables, such as inks or chemicals. This reduces waste, lowers operating costs, and minimizes the environmental impact of PCB manufacturing. The absence of consumables also simplifies the marking process and reduces maintenance requirements.

Applications of UV and CO2 Laser Marking in the PCB Industry

Both UV and CO2 lasers are used in PCB marking, each offering specific advantages for different applications:

| Характеристика | UV-лазер | CO2-лазер |

| Applicable Materials | Metals (copper foil), solder mask, PI film, etc. | Non-metallic substrates (FR-4, polyimide, ceramic substrates) |

| Processing Type | Cold processing (photochemical decomposition) | Thermal processing (ablation/carbonization) |

| Точность | ≤20µm ultra-fine marking (HDI board micro-hole marking) | 50-100µm (outer layer characters, thick lines) |

| Heat Affected Zone | Very small, suitable for flexible materials such as FPC | Larger, may cause slight deformation of the substrate |

| Typical Applications | Chip-level two-dimensional code | PCB board edge barcode |

| Blind hole alignment mark | Substrate serial number | |

| Flexible board PI cover film window opening | Large-size panel marking | |

| Стоимость и обслуживание | High equipment cost, but comprehensive accuracy advantage is obvious | Lower cost, suitable for conventional needs |

Four Reasons to Choose Zixu Laser Marking Equipment

Choosing the right laser marking equipment is crucial for achieving optimal results. Компания Zixu offers several compelling reasons to consider their laser marking solutions:

High-Quality Equipment: Zixu is known for producing high-quality and reliable laser marking equipment. Their machines are built to last and deliver consistent performance, ensuring long-term value and minimizing downtime.

Передовые технологии: Zixu incorporates the latest laser technology into their equipment, ensuring high precision, speed, and flexibility. Their machines are designed to meet the demanding requirements of modern PCB manufacturing.

Comprehensive Solutions: Zixu offers a wide range of laser marking solutions to cater to different needs and applications. They provide both UV and CO2 laser marking systems, allowing customers to choose the best technology for their specific requirements.

Excellent Customer Support: Zixu provides excellent customer support, including installation, training, and maintenance services. Their team of experts is available to assist customers with any questions or issues, ensuring a smooth and hassle-free experience.

Laser marking has revolutionized the PCB industry, offering a superior alternative to traditional marking methods. Its advantages in precision, speed, flexibility, and permanence make it an indispensable tool for modern PCB manufacturing. By choosing the right laser marking equipment, such as those offered by Zixu, manufacturers can enhance their production processes, improve product quality, and gain a competitive edge in the market.

Recommended Products