All You Need to Know About UV Laser Marking Machines

лазерные маркираторы UV have emerged as a cutting-edge technology in material processing, offering high precision, flexibility, and efficiency. Unlike traditional marking methods, UV laser marking utilizes short-wavelength ultraviolet lasers to create permanent, high-quality marks on a wide range of materials. This article will delve into the working principle of UV laser marking machines, explore the suitable materials for this technology, and examine its diverse applications across various industries.

The Working Principle of UV Laser Marking Machines

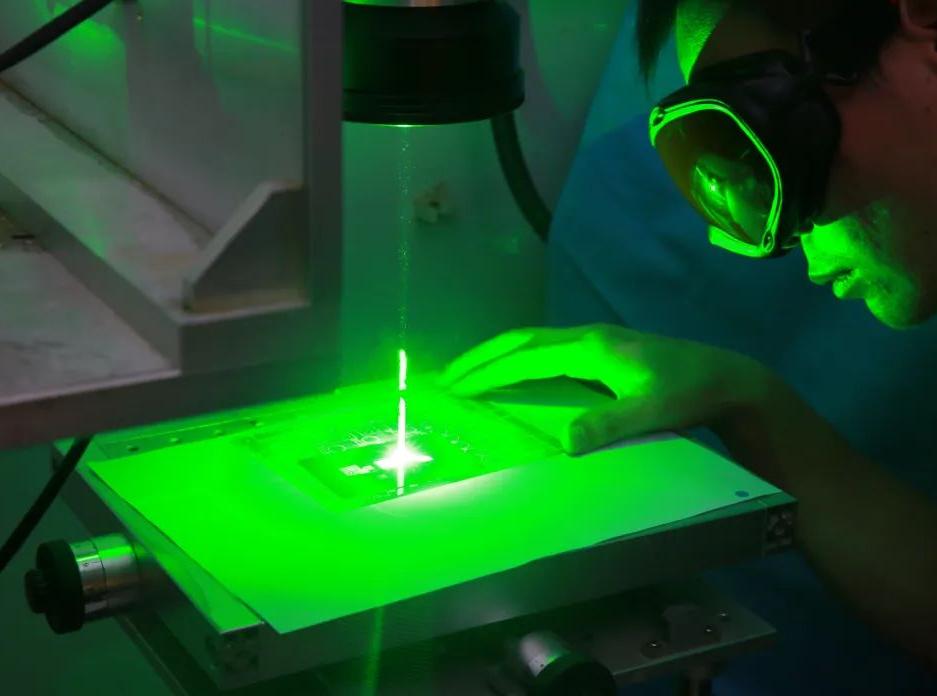

A UV laser marking machine is a marking equipment that operates on the principle of laser technology. When a laser beam passes through a gain medium, photons undergo stimulated emission, emitting photons of the same frequency, resulting in a beam of light with high monochromaticity, coherence, and directionality.

In a UV laser marking machine, the laser is generated by ionizing a gas. The laser cavity is filled with a gaseous medium. When a high voltage is applied, the gas molecules ionize, releasing electrons. These ions recombine with atoms, producing a beam of light containing both visible and ultraviolet wavelengths. This is how the laser is generated. Through an optical path, the laser is collimated and then focused onto the marking material by a lens. These lasers emit short-pulse, high-intensity light that interacts with the material’s surface. Depending on the material and the desired marking effect, the laser energy can induce various phenomena.

- Ablation: In this process, the laser energy removes material from the surface, creating a permanent mark by vaporizing or sublimating the material. This is commonly used for marking metals, ceramics, and some plastics.

- Изменение цвета: For certain materials, the laser energy can induce a color change. This can be achieved by altering the material’s molecular structure or creating microscopic surface modifications that interfere with light reflection.

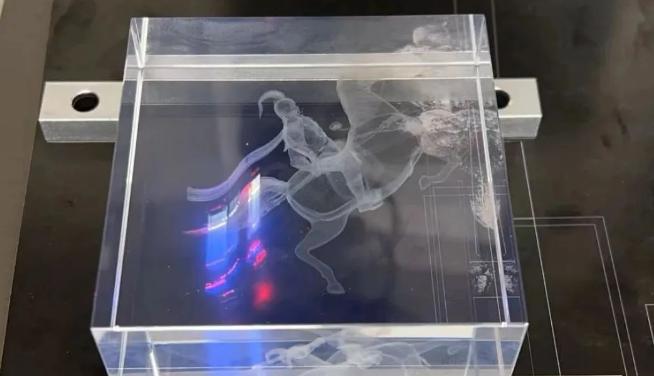

- Marking on Transparent Materials: UV lasers can be used to mark transparent materials like glass and some plastics by focusing the beam within the material. This creates a localized area of stress that alters the refractive index, resulting in a visible mark.

Suitable Materials for UV Laser Marking

UV laser marking machines offer versatility in terms of the materials they can process. Some of the most commonly marked materials include:

- Металлы: Stainless steel, aluminum, copper, brass, gold, silver, titanium

- Пластмассы: Many types of plastics, including ABS, PC, PMMA, PET, and some UV laser marking machines for plastic specifically designed for these materials.

- Керамика: Стекло, ceramics, sapphire

- Semiconductors: Silicon, gallium arsenide

- Дерево: Some types of wood can be marked with UV lasers.

- Other Materials: Some polymers, rubbers, and even certain types of paper can be marked with appropriate laser parameters.

Application Scenarios of UV Laser Marking Machine

The versatility of UV laser marking machines has led to their widespread adoption across various industries:

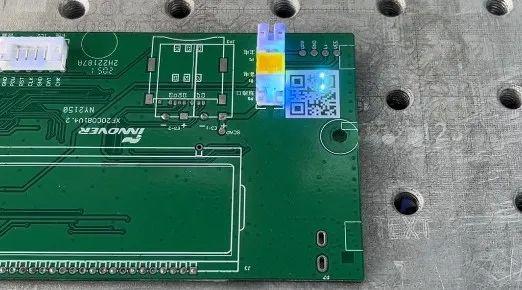

Precision Electronics Industry

Application of UV Laser Marking Machine in the Precision Electronics Industry

Marking serial numbers, barcodes, logos, and other identifying information on electronic components, integrated circuits (ICs), printed circuit boards (PCBs), and other electronic devices. For example, marking production batches and serial numbers on chips.

Medical Equipment Industry

Marking medical devices with clear and durable markings. For example, marking unique identification codes, sterilization dates, and manufacturer information on medical implants, surgical instruments, and other medical devices.

Food Packaging Industry

Marking batch numbers, expiration dates, and other important information on food packaging materials. For example, marking production dates and expiration dates on plastic bottles and paper boxes.

Jewelry Industry

Marking valuable items such as crystals, jewelry, and gemstones to enhance their value. For example, marking logos, brand names, and unique identification numbers on jade and crystal.

Other Industries

With its short wavelength and concentrated energy, UV light is ideal for fine processing and is widely used in high-end applications such as marking on smartphone screens, keyboards, mice, and chargers.

Advantages of UV Laser Marking Machines

Высокая эффективность: Traditional marking methods such as mechanical engraving and chemical etching are not only slow but also have low precision, failing to meet the demands of modern industrial production. In contrast, UV laser marking machines use laser beams to complete a large number of marking tasks in a short time, with higher precision, significantly improving production efficiency.

Высокая точность: Due to the short wavelength and concentrated energy of ultraviolet lasers, they can create very small markings on the material surface, reaching the micrometer or even nanometer level. This high-precision marking not only enhances the aesthetics but also increases the added value of the product, helping to improve the company’s image.

Ease of Operation: UV laser marking machines can be easily automated through computer control. Moreover, the operation of UV laser marking machines is simple and easy to understand, requiring only simple training to use. This operational convenience greatly improves production efficiency and quality.

Non-destructive Marking: UV laser marking machines can mark materials without damaging the surface, avoiding the problems of material damage and scrap that may occur with traditional marking methods. This non-destructive marking technology is widely used in various materials such as metals, plastics, and glass, effectively improving the accuracy of product quality inspection and anti-counterfeiting traceability.

Energy-efficient and Environmentally Friendly: UV laser marking machine uses photolithography for marking, without the need for ink, chemicals and other consumables, in line with the requirements of modern green production, and has relatively low energy consumption.

UV Laser Marking Machine Manufacturer – Zixu

UV laser marking machines have revolutionized material processing across various industries. With their high precision, versatility, and efficiency, they offer numerous advantages over traditional marking methods.

Компания Zixu, with years of research and development experience in laser marking machines, has developed a range of standard and customized automated UV laser marking equipment to meet diverse industrial needs.

Our reliable UV laser marking machines can be used on almost all common workpiece materials, especially non-metals such as plastics, acrylic, glass, ceramics, paper, crystal, diamond, silicon wafers, silicone, wood, paper, and textiles, as well as metals like stainless steel, aluminum, copper, gold, silver, chromium, and platinum.

Recommended Products