Многие из наших клиентов начального уровня планируют или уже внедрили системе выполнения производства (MES) для высокой эффективности, низкого уровня отходов и управления производством в реальном времени. Вся наша линейка лазеров может быть сконфигурирована или модернизирована с помощью плат управления для поддержки систем MES. Эта функция также является стандартной для наших автоматизированных лазерных систем.

Основные характеристики

| Доступно на | Все настольные, шкафные и подвесные системы |

| Кодирование контента | Дата производства, номер партии, номер товара, QR-код или индивидуальный зака |

| Режим кодирования | Распространение через MES через онлайн-компьютер |

| Объем работ по процессу | На основе использования и конфигурации или заказа |

| Режим повторения | Вручную с помощью настраиваемых приспособлений |

Улучшайте стабильное качество и максимально увеличивайте производительность для получения максимальной прибыли.

Выберите функции автоматизации и интеллекта, которые вам больше всего нужны в рамках вашего бюджета, чтобы преодолеть текущие узкие места и достичь оптимальной производительности, обеспечивая при этом постоянное качество во всех процессах лазерной маркировки, сварки и очистки. Наши решения по автоматизации и интеллекту могут также сэкономить вам много повторяющейся работы и обеспечить более высокую окупаемость инвестиций.

Реагируйте быстрее и лучше на потребности ваших клиентов или рынка.

Спрос постоянно меняется, и максимально быстрое реагирование на него может создать или разрушить ваш бизнес. Вот почему вам нужны более гибкие производственные возможности для быстрого переключения между различными частями процесса и достижения экологичной устойчивости с низким потреблением. Наши экономичные автоматизированные лазерные решения сократят ваши потери ресурсов и времени и будут способствовать вашему успеху.

Продолжайте внедрять инновации до тех пор, пока вы не перепишете правила своей отрасли или не измените мир.

В сегодняшней промышленной революции 4.0 сохранение креативности является ключевым фактором формирования и укрепления основных компетенций. Воспользуйтесь нашими экономически эффективными и гибкими решениями по автоматизации, чтобы превратить ваш постоянный поток идей в готовые продукты и улучшить их для будущей реальности. Мы продолжим поддерживать вашу креативность и с нетерпением ждем вашего успеха.

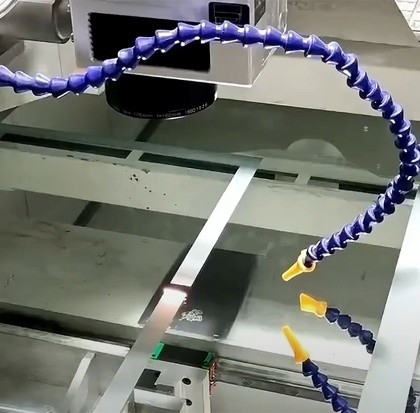

Мы предлагаем опциональные модули CCD для различных лазерных систем для визуального осмотра и распознавания заготовок и сканирования рабочей зоны для дальнейшего повышения точности и согласованности процесса, достижения более высокого качества продукции и сокращения времени, затрачиваемого на смену приспособлений. Кроме того, визуальное распознавание CCD и сопоставление данных с системой MES может сократить потери, вызванные неправильной эксплуатацией.

Основные характеристики

| Доступно на | Все настольные, шкафные и подвесные системы |

| Определить ставку | 5 кГц или настраиваемый |

| Динамический Фокус | Необязательный |

| Устойчивость к повторению | ±0,01мм |

| Режим движения | Поточная линия и шаговый двигатель |

Улучшайте стабильное качество и максимально увеличивайте производительность для получения максимальной прибыли.

Выберите функции автоматизации и интеллекта, которые вам больше всего нужны в рамках вашего бюджета, чтобы преодолеть текущие узкие места и достичь оптимальной производительности, обеспечивая при этом постоянное качество во всех процессах лазерной маркировки, сварки и очистки. Наши решения по автоматизации и интеллекту могут также сэкономить вам много повторяющейся работы и обеспечить более высокую окупаемость инвестиций.

Реагируйте быстрее и лучше на потребности ваших клиентов или рынка.

Спрос постоянно меняется, и максимально быстрое реагирование на него может создать или разрушить ваш бизнес. Вот почему вам нужны более гибкие производственные возможности для быстрого переключения между различными частями процесса и достижения экологичной устойчивости с низким потреблением. Наши экономичные автоматизированные лазерные решения сократят ваши потери ресурсов и времени и будут способствовать вашему успеху.

Продолжайте внедрять инновации до тех пор, пока вы не перепишете правила своей отрасли или не измените мир.

В сегодняшней промышленной революции 4.0 сохранение креативности является ключевым фактором формирования и укрепления основных компетенций. Воспользуйтесь нашими экономически эффективными и гибкими решениями по автоматизации, чтобы превратить ваш постоянный поток идей в готовые продукты и улучшить их для будущей реальности. Мы продолжим поддерживать вашу креативность и с нетерпением ждем вашего успеха.

Решения с летающим лазером широко используются в автоматизированных процессах на производственных линиях. Эта технология экономит много человеческих ресурсов и обеспечивает высокую точность и скорость в эффективности процесса. Примерами служат автоматизированная маркировка даты производства для пластиковой упаковки, автоматизированная криволинейная сварка в автомобильной промышленности, автоматизированное удаление ржавчины и грязи на судах и т. д. В то же время ее можно комбинировать с модулем CCD для достижения лучшего качества процесса.

Основные характеристики

| Режим движения | Поточная линия и шаговый двигатель |

| Максимальная скорость процесса | <70000мм/с |

| Объем работ | На основе использования и конфигурации или заказа |

| Устойчивость к повторению | ±0,01 мм с CCD и динамической фокусировкой |

| Многоосевое управление | Дополнительное управление осями 2/3/4/6 |

Улучшайте стабильное качество и максимально увеличивайте производительность для получения максимальной прибыли.

Выберите функции автоматизации и интеллекта, которые вам больше всего нужны в рамках вашего бюджета, чтобы преодолеть текущие узкие места и достичь оптимальной производительности, обеспечивая при этом постоянное качество во всех процессах лазерной маркировки, сварки и очистки. Наши решения по автоматизации и интеллекту могут также сэкономить вам много повторяющейся работы и обеспечить более высокую окупаемость инвестиций.

Реагируйте быстрее и лучше на потребности ваших клиентов или рынка.

Спрос постоянно меняется, и максимально быстрое реагирование на него может создать или разрушить ваш бизнес. Вот почему вам нужны более гибкие производственные возможности для быстрого переключения между различными частями процесса и достижения экологичной устойчивости с низким потреблением. Наши экономичные автоматизированные лазерные решения сократят ваши потери ресурсов и времени и будут способствовать вашему успеху.

Продолжайте внедрять инновации до тех пор, пока вы не перепишете правила своей отрасли или не измените мир.

В сегодняшней промышленной революции 4.0 сохранение креативности является ключевым фактором формирования и укрепления основных компетенций. Воспользуйтесь нашими экономически эффективными и гибкими решениями по автоматизации, чтобы превратить ваш постоянный поток идей в готовые продукты и улучшить их для будущей реальности. Мы продолжим поддерживать вашу креативность и с нетерпением ждем вашего успеха.

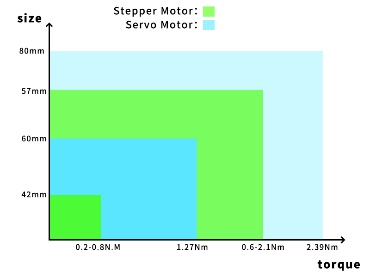

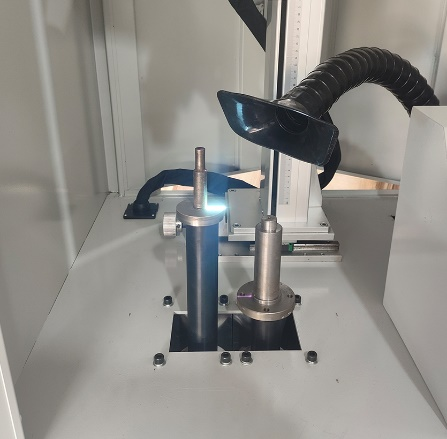

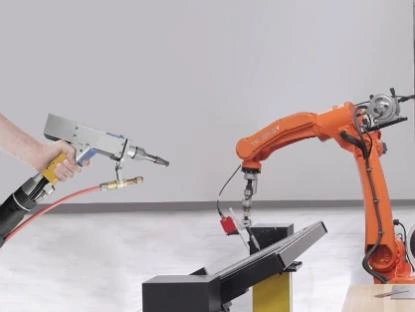

Будь то лазерная маркировка, гравировка, резка, сварка или очистка, многоосевые системы являются широко распространенными решениями в области автоматизации, призванными минимизировать влияние человеческого вмешательства за счет использования шаговых двигателей или серводвигателей для точного управления, повышения стабильности качества процесса и снижения риска травматизма из-за неисправностей оборудования и других непредвиденных факторов.

Основные характеристики

| Axes | 3, 4, 5 or 6 axes as required |

| Contour Following Accuracy | Down to ±0.003mm |

| Repeat Accuracy | Down to 0.002mm |

| Motor | Servo or Stepper NEMA 17 (42mm), NEMA 23 (57mm), NEMA 24 (60mm) or NEMA 32 (80mm) depending on requirements |

Начните создавать свое автоматизированное лазерное решение по функциям

Нужна многофункциональная лазерная станция обработки? Или интересуетесь новым применением лазерных технологий?

Поразительная точность

Будь то лазерная маркировка, гравировка, сварка или очистка, мы предлагаем индивидуальные решения и конфигурации, основанные на фактических размерах вашей детали, целях по качеству, целях по точности и целях по эффективности процесса, обеспечивая лидирующие в отрасли точность и повторяемость даже в самых экономичных конфигурациях.

Поддерживайте определенное качество, но быстрее.

Применяемые вместо человеческого труда в крупносерийном производстве, стабилизированные механические оси сокращают отходы, возникающие из-за усталости оператора, нарушений окружающей среды или других факторов, которые могут привести к разрушению детали или необходимости ее доработки, и особенно подходят для автоматизированного массового производства тысяч или даже миллионов деталей.

Увеличьте использование пространства, преодолевая ограничения

Маркировка, гравировка, сварка или очистка с помощью гальво-лазера может обеспечить превосходный контроль точности, но максимальный рабочий диапазон часто ограничен линзой гальво, и система, как правило, требует более мощных лазеров, что приводит к резкому росту затрат. Правильно настроив многоосевую систему управления, этого можно добиться с гораздо меньшими размерами и весом машины и с гораздо более экономичной конфигурацией.

Что следует учитывать перед настройкой автоматизированного или интеллектуального решения?

У нас большой опыт работы в области лазерной маркировки, сварки и очистки с компаниями из самых разных отраслей промышленности, и чем конкретнее потребности вашего бизнеса, тем более точные варианты мы можем вам предложить.

- Шаг 1: Оцените требования к производительности, качеству и гибкости ваших текущих или планируемых лазерных процессов;

- Шаг 3: Проконсультируйтесь с нами по поводу наиболее экономичного решения по автоматизации или интеллектуальному управлению, а также лучшей конфигурации;

- Шаг 2: Оцените экономию труда и времени, которую можно достичь за счет использования автоматизации или интеллектуальных решений;

- Наконец, запросите смету, чтобы убедиться, что ваши потребности и бюджет будут удовлетворены.

Проблемы с возвратом инвестиций?

Проблемы с возвратом инвестиций?

Ускорьте производство с помощью наших интеллектуальных технологий автоматизации.

Мы стремимся развивать автоматизацию и интеллект задач лазерной маркировки, сварки и очистки, чтобы улучшить качество и последовательность результатов задач и сократить затраты на рабочую силу, чтобы максимизировать производительность и окупаемость инвестиций наших клиентов. Мы предлагаем совместимые с системе выполнения производства (MES)стандартизированные лазерные системы с дополнительными летательными модулями и модулями приборов с зарядовой связью (CCD), чтобы вы могли оценить свои фактические потребности и сделать гибкий выбор.

Постоянное качество

Автоматизированные лазерные системы обеспечивают точные и эффективные операции по маркировке, сварке и очистке материалов, которые трудно выполнить с помощью обычного технологического оборудования, сохраняя при этом эффективность и качество задач;

Автоматическое сопоставление

наша полностью автоматическая лазерная система может быть подключена к MES, считывать и вводить существующие коды через систему CCD, а затем переходить к следующему процессу в соответствии с предварительно заданным технологическим процессом;

Гибкость

автоматизированные лазерные системы обеспечивают гибкое управление технологическими процессами, особенно для сценариев мелкосерийного и индивидуального производства, позволяя компаниям быстро реагировать на изменения рынка и удовлетворять уникальные потребности своих клиентов;

Экономия средств и повышение производительности

автоматизированные лазерные системы могут значительно повысить эффективность за счет сокращения ручного труда, времени и затрат. Кроме того, интеллектуальные решения по автоматизации предлагают многочисленные преимущества в плане эффективности и наглядности.