Chassis Number Marking Machine: Manual vs. Automated Types

In industries like automotive manufacturing, the chassis number plays a crucial role in identifying, tracking, and authenticating vehicles. To guarantee each vehicle is uniquely identifiable, a chassis number marking machine is used to engrave the number onto the vehicle’s frame or body. There are two primary types of chassis number marking machines: manual and automated. Each type offers unique features and advantages, making them suitable for different production requirements. Let’s take a closer look at both options.

Application of Chassis Number Marking

Chassis number marking(VIN marking)plays a critical role in the automotive industry, serving several important functions. Here are the main applications:

- Vehicle Identification: The chassis number serves as a distinct identifier for every vehicle, allowing manufacturers, authorities, and owners to track and distinguish one vehicle from another. It guarantees that each car, truck, or motorcycle is uniquely recognized.

- Regulatory Compliance: Regulatory agencies and governments mandate that vehicles display a chassis number to adhere to legal requirements. This marking ensures vehicles meet safety, emissions, and environmental standards while also streamlining the registration process.

- Security and Anti-Theft Measures: Chassis numbers are integral in preventing vehicle theft and fraud. If a vehicle is stolen, the chassis number is a permanent record that can be traced back to its rightful owner, making it more difficult for stolen vehicles to be resold.

- Tracking Maintenance and Warranty: The chassis number is also used to maintain service records and warranty claims. It ensures that a vehicle’s history is accurately documented, helping both manufacturers and service providers track repairs and parts replacements.

These functions are essential for ensuring transparency, traceability, and security throughout a vehicle’s lifecycle.

Manual Chassis Number Marking Machines

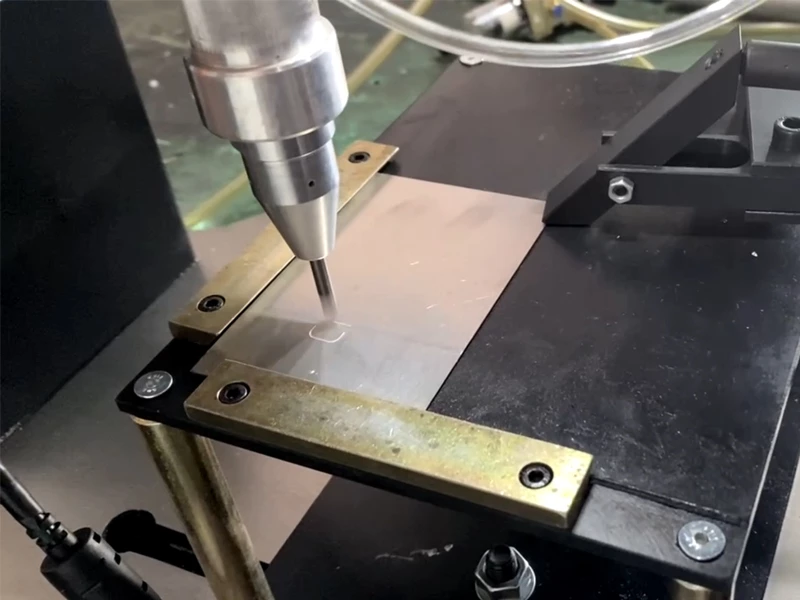

Manual chassis number marking machines are operated by hand and are commonly used in smaller-scale manufacturing settings or for low-volume production lines. These machines allow operators to manually guide the marking tool to etch the chassis number onto the vehicle’s frame.

- The main advantage of manual machines is their affordability; they require a lower initial investment compared to automated systems, making them a good option for small manufacturers or startups.

- They also offer flexibility, allowing for customization of chassis number formats and placement depending on the specific needs of each vehicle type.

- However, manual marking is labor-intensive, requiring more time and effort from operators, which can slow down production rates.

- Additionally, the quality of the markings depends on the operator’s skill, making it prone to human error and inconsistencies.

As a result, manual marking may not be ideal for high-volume production, where precision and speed are critical.

Automated Chassis Number Marking Machines

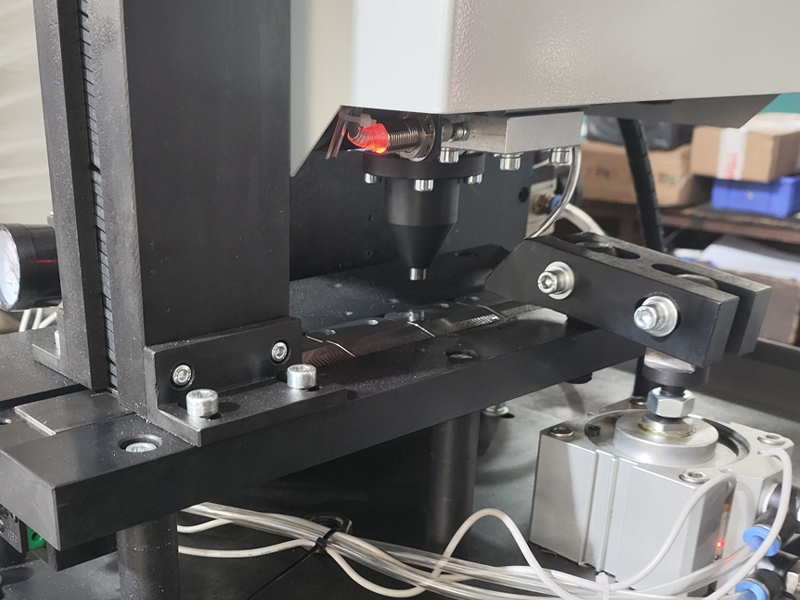

Automated chassis number marking machines use advanced technology, such as laser engraving or robotic arms, to mark the chassis number with precision and speed. These systems are ideal for high-volume production lines, where consistency and efficiency are crucial. Once set up, automated machines require minimal human intervention, allowing for continuous, hands-free operation.

- The primary advantages of automated machines include fast, high-precision markings that are uniform across large batches of vehicles. This results in accurate, permanent markings that are difficult to alter or tamper with.

- Automated systems also reduce the risk of human error, enhancing the reliability of vehicle identification. However, these machines come with a higher initial investment and may require specialized maintenance and repairs.

While automated machines are less flexible than manual systems in terms of customization, they are optimal for manufacturers with large-scale production needs looking to boost output while ensuring accuracy and reducing labor costs.

Manual vs. Automated Marking Chassis Number Marking Machines

When choosing between manual and automated chassis number marking machines, several factors must be considered, including production volume, cost, precision, and flexibility. Below is a comparison to help you decide which option is best for your needs.

| Factor | Manual Chassis Number Marking Machines | Automated Chassis Number Marking Machines |

| Production Volume | Ideal for low-volume or small-scale operations. | Best for high-volume or mass production environments. |

| Cost | Lower upfront cost, more budget-friendly for small businesses. | Higher initial investment, but reduces labor costs in the long run. |

| Accuracy | Dependent on the operator’s skill, can result in inconsistencies. | High precision and consistency with minimal error, ideal for standardized markings. |

| Speed and Efficiency | Slower process due to manual operation, less efficient for large batches. | Fast, continuous operation with high throughput and minimal downtime. |

| Labor Involvement | Requires constant human intervention and manual labor. | Minimal human intervention, reducing labor requirements. |

| Flexibility | Flexible for custom marking styles and small batches. | Less flexible, optimized for high-volume, standardized production. |

| Maintenance | Simple and less costly to maintain. | Requires regular maintenance, can be costly to repair if complex systems break down. |

| Risk of Errors | Higher risk of human error, inconsistent results. | Very low risk of errors, uniform and reliable markings. |

So, we can make a conclusion:

- Manual Marking Machines: Ideal for smaller operations that require flexibility and customization, manual marking machines offer lower initial costs. However, they tend to be slower and more prone to errors, making them best suited for businesses with lower production volumes.

- Automated Marking Machines: Designed for large-scale production, automated machines provide faster speeds, enhanced accuracy, and greater efficiency. Although they come with a higher initial investment, they can help reduce labor costs and improve consistency, making them perfect for manufacturers with high-volume needs.

By evaluating production requirements, cost constraints, and the need for precision, manufacturers can make an informed choice between manual and automated chassis number marking machines.

Choose Which One?

When deciding between manual and automated chassis number marking machines, manufacturers must consider several factors.

- For Low-Volume or Custom Manufacturers: If you have a low production volume or need flexibility to mark different types of vehicles or customizations, a manual marking machine could be the better option. With a lower initial investment, it’s well-suited for smaller businesses or manufacturers on a budget. Manual machines offer greater control over the marking process and can accommodate slight variations in speed or precision, making them ideal for businesses that don’t require high throughput.

- For High-Volume or Mass Production Manufacturers: Automated marking machines are the best fit for large-scale manufacturers or those producing vehicles in high volumes. The speed, consistency, and precision of automated machines significantly improve productivity, making them ideal for environments where quick turnaround times and high accuracy are crucial. Despite the higher initial investment, automated systems reduce long-term labor costs and the risk of human error, making them the optimal solution for manufacturers looking to scale their operations efficiently.

Ultimately, the decision between manual and automated chassis number marking machines depends on factors such as production requirements, budget, and the desired level of precision. Assess your specific needs to make an informed choice that will best enhance your manufacturing processes.

In conclusion, both manual and automated chassis number marking machines serve important roles in vehicle production. The key is to evaluate your specific requirements, such as volume, budget, and flexibility, to select the most appropriate solution for your needs.

For any need about chassis number marking machines, you can contact our service team.

Recommended Products