Различные методы лазерной маркировки на коже: Сравнительный анализ

Обработка кожи - это искусство, сочетающее в себе традиции и технологии, особенно когда речь идет о гравировке. Лазерные гравировальные станки - это инновационная технология обработки кожи, повышающая точность, скорость и универсальность.

В этой статье мы подробно рассмотрим различные методы лазерной маркировки кожи, изучим типы кожи, которые подходят для этих методов, проведем сравнительный анализ методов и поможем вам выбрать подходящий. кожа лазерная маркировочная машина.

Типы Техника лазерной маркировки

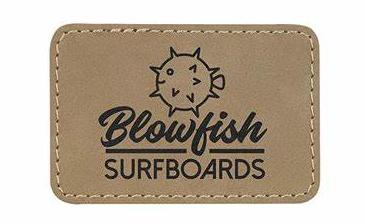

Лазерная маркировка - это бесконтактный процесс, в котором используется сфокусированный лазерный луч для создания постоянных следов на материалах. В случае с кожей лазерный луч может использоваться для гравировки, травления или окрашивания поверхности. Различные лазерные технологии используют разные длины волн и плотность энергии, что приводит к различным характеристикам маркировки.

Лазерная маркировка CO2

CO2-лазеры испускают инфракрасное излучение с длиной волны 10,6 микрона. Эта длина волны сильно поглощается большинством материалов, включая кожу. Когда лазерный луч фокусируется на поверхности кожи, он вызывает быстрый нагрев и испарение материала, оставляя после себя несмываемый след.

Преимущества:

- Возможность глубокой гравировки, подходящая для создания замысловатых рисунков.

- Высококачественные знаки с четкими краями и хорошим контрастом.

- Может использоваться как для резки, так и для маркировки кожи.

Недостатки:

- Возможность термического повреждения кожи, особенно для тонких или деликатных материалов.

- Более высокое потребление энергии по сравнению с другими лазерными методами.

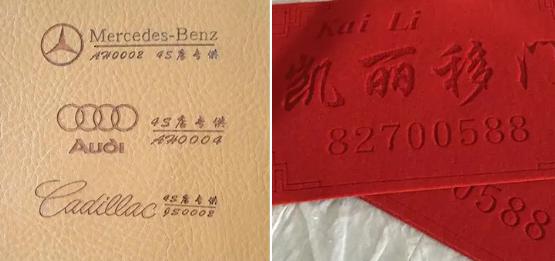

Волоконно-лазерная маркировка

Волоконные лазеры испускают излучение ближнего инфракрасного диапазона с длиной волны около 1064 нанометров. Эта длина волны поглощается металлами и некоторыми пигментами, но не так сильно органическими материалами, такими как кожа. Поэтому маркировка волоконным лазером обычно приводит к изменению цвета, а не к физическому удалению материала.

Преимущества:

- Высокая точность и аккуратность, подходит для тонкой маркировки и штрихкодирования.

- Высокая скорость, позволяющая эффективно маркировать большие объемы кожи.

- Низкое энергопотребление, что делает его более экономичным вариантом.

Недостатки:

- Ограниченная глубина маркировки по сравнению с CO2-лазерами.

- Для достижения оптимального результата может потребоваться предварительная обработка поверхности кожи, особенно для темной или сильно пигментированной кожи.

Ультрафиолетовая лазерная маркировка

Ультрафиолетовые лазеры испускают ультрафиолетовое излучение с длиной волны, как правило, от 266 до 355 нанометров. Эта длина волны поглощается органическими материалами, в том числе кожей, но не вызывает значительных термических повреждений. Ультрафиолетовая лазерная маркировка часто используется для изменения цвета или для удаления поверхностного слоя, не затрагивая основной материал.

Преимущества:

- Бесконтактная маркировка, сводящая к минимуму риск повреждения поверхности кожи.

- Минимальное тепловое воздействие, сохраняющее целостность кожи.

- Подходит для деликатных или тонких кожаных материалов.

Недостатки:

- Меньшая глубина маркировки по сравнению с CO2 и волоконными лазерами.

- Для определенных типов кожи могут потребоваться специальные длины лазерных волн или предварительная обработка.

Распространенные виды кожи для лазерной маркировки

Когда речь идет о лазерной маркировке, различные типы кожи дают разные результаты благодаря своим отличительным свойствам. Понимание этих типов может помочь в выборе наиболее подходящей техники лазерной маркировки для достижения желаемых результатов.

- Полностью зернистая кожа: Это кожа высочайшего качества, сохранившая весь зерновой слой шкуры. Полнозернистая кожа ценится за свою долговечность и естественную текстуру. Она очень хорошо реагирует на CO2-лазеры, которые позволяют получить детальные и долговечные следы. Натуральные масла и волокна, содержащиеся в полнозернистой коже, часто приводят к глубоким, насыщенным гравировкам, которые подчеркивают уникальный характер кожи.

- Верхняя зернистая кожа: Немного более обработанная, чем цельная кожа, кожа top-grain подверглась шлифовке и обработке для устранения дефектов. Она по-прежнему высококачественная, но менее прочная, чем полнозернистая кожа. CO2- и УФ-лазеры хорошо работают с зернистой кожей, создавая четкие и точные следы. Обработка зернистой кожи может повлиять на глубину и выраженность следов.

- Скрепленная кожа: Изготовленная из обрезков и волокон, скрепленных клеем, бондарная кожа менее прочна, чем цельнозерновая или высокозерновая. Она обычно хорошо маркируется CO2-лазерами, хотя качество может варьироваться в зависимости от состава кожи и ее покрытия. Следы могут быть не такими четкими и глубокими, как на высококачественной коже.

- Синтетическая кожа: Искусственная кожа, состоящая из пластика и других искусственных материалов, требует тщательного подхода к лазерной маркировке. Ультрафиолетовые лазеры часто предпочитают из-за их способности наносить маркировку с высокой точностью и минимальным риском повреждения. Также можно использовать CO2 и волоконные лазеры, но результаты могут отличаться в зависимости от конкретного состава синтетики.

Понимая эти типы кожи, вы сможете лучше подобрать технику лазерной маркировки для достижения наилучших результатов в ваших проектах.

Сравнительный анализ

Чтобы помочь разобраться в различиях между методами лазерной маркировки, приведем сравнительный анализ, представленный в виде таблицы:

| Характеристика | CO2-лазер | Волоконный лазер | UV-лазер |

| Точность и детализация | Хорошая точность; эффективен для различных типов кожи. | Высокая точность; оставляет четкие и ясные следы на предварительно обработанной коже. | Высочайшая детализация и разрешение; идеально подходит для сложных рисунков и высококонтрастной разметки. |

| Скорость обработки | Умеренная скорость; подходит для многих задач, но медленнее других. | Быстро и эффективно; идеально подходит для крупносерийного производства. | Медленнее, чем волоконные лазеры; превосходно детализирует, но менее пригоден для быстрой обработки. |

| Стоимость и обслуживание | Как правило, более доступны по цене; не требуют особого ухода. | Более высокая первоначальная стоимость; меньшая потребность в обслуживании и более длительный срок службы. | Как правило, самый дорогой; требует специализированного обслуживания, но обеспечивает высочайшую точность. |

| Совместимость с кожей | Универсальна; хорошо подходит для натуральных кож, таких как full-grain и top-grain. | Эффективен для предварительно обработанной кожи; менее идеален для необработанной кожи. | Лучше всего подходит для искусственной кожи и материалов с покрытием; менее эффективен для необработанной натуральной кожи. |

| Качество маркировки | Позволяет получать высококачественные знаки; подходит для детального дизайна, но с некоторыми ограничениями. | Обеспечивает четкие и резкие следы; эффективен как для поверхностной, так и для глубокой гравировки. | Обеспечивает исключительное качество с мелкими деталями; идеально подходит для высококонтрастных и замысловатых узоров. |

В этой таблице приведены основные различия между методами лазерной маркировки CO2, волоконным и ультрафиолетовым лазерами, что поможет вам выбрать подходящий метод в зависимости от ваших конкретных потребностей и требований.

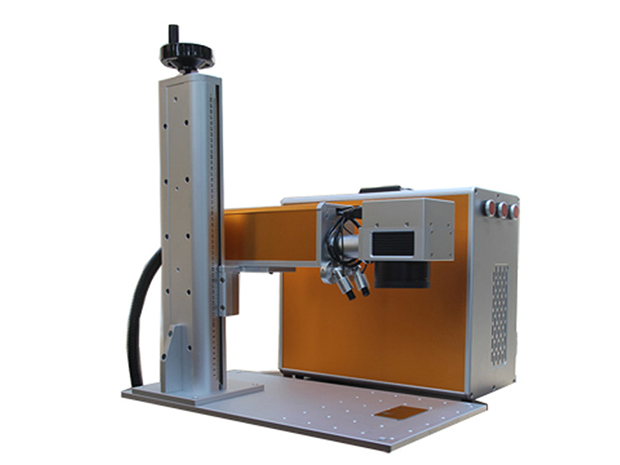

Выбор правильного Кожа лазерная маркировка машина

Выбор подходящей машины для лазерной маркировки кожи включает в себя рассмотрение нескольких ключевых факторов, чтобы убедиться, что оборудование отвечает вашим конкретным потребностям. Вот некоторые важные аспекты, которые необходимо оценить:

- Тип кожи: Выбирайте оборудование, совместимое с типами кожи, с которыми вы планируете работать. Например, УФ-лазеры высокоэффективны для синтетических кож и материалов с покрытием, а CO2-лазеры универсальны для натуральных кож, таких как full-grain и top-grain.

- Требования к маркировке: Оцените уровень детализации и точности, требуемый для ваших рисунков. Если вам нужна сложная маркировка с высоким разрешением, лучшим выбором может стать ультрафиолетовый лазер. Для общей гравировки и резки подойдут CO2 или волоконные лазеры.

- Бюджет и экономическая эффективность: Сбалансируйте первоначальную стоимость оборудования с долгосрочными расходами на обслуживание. CO2-лазеры обычно более доступны по цене и требуют меньшего обслуживания, в то время как волоконные лазеры имеют более высокую начальную стоимость, но меньшую потребность в обслуживании. Ультрафиолетовые лазеры, несмотря на исключительную точность, как правило, самые дорогие.

- Объем производства: Учитывайте объем производства и скорость обработки. Волоконные лазеры идеально подходят для крупносерийного производства благодаря своей скорости и эффективности. Если ваши производственные потребности ниже, CO2-лазеры могут обеспечить адекватную производительность по более выгодной цене.

Тщательно оценив эти факторы, вы сможете выбрать лазерный маркировочный станок, который будет соответствовать вашим потребностям в маркировке кожи, обеспечивая качество и эффективность вашей работы.

Заключение

Лазерная маркировка на коже обеспечивает точность и универсальность, при этом каждый метод имеет свои преимущества. CO2-лазеры экономичны и универсальны для натуральной кожи, волоконные лазеры обеспечивают скорость и точность, а УФ-лазеры - исключительную детализацию для синтетических материалов. Выбор подходящего оборудования зависит от типа кожи, потребностей в маркировке и бюджета, что гарантирует оптимальные результаты для ваших кожаных изделий.

Для получения дополнительной информации о лазерной маркировки кожи машины или покупке рекомендации, пожалуйста, не стесняйтесь связаться с нами.

Recommended Products