Точечный гравер или лазерный маркировочный станок: Как выбрать?

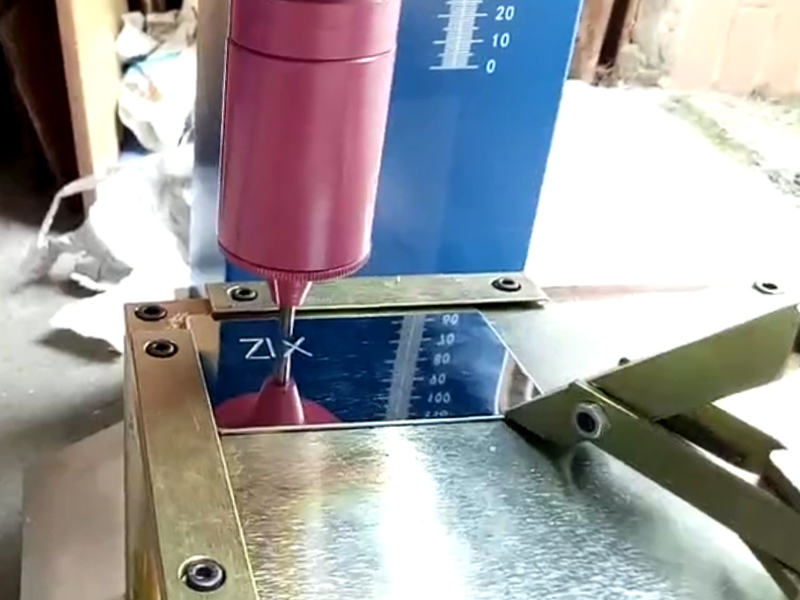

Необходимость в точной и долговечной маркировке продукции сегодня приобрела первостепенное значение. Будь то отслеживание товарных запасов, обеспечение контроля качества или добавление фирменного стиля, постоянная маркировка необходима. В этой области доминируют две основные технологии: точечная гравировка и лазерная маркировка. Каждая из них имеет свои преимущества и ограничения, что делает выбор между ними важным решением для производителей и предприятий.

Эта статья призвана пролить свет на эти две технологии, изучить их ключевые особенности, достоинства и недостатки. В конце статьи вы получите знания, необходимые для принятия взвешенного решения о том, какой станок лучше всего подходит для ваших конкретных потребностей в маркировке. Мы рассмотрим такие факторы, как совместимость материалов, глубина маркировки, скорость, качество, стоимость и безопасность, чтобы предоставить всестороннее сравнение.

Понимание основ

| Точечная гравировка(Гравировальный станок) | Лазерная маркировка(Лазерная маркировочная машина) | |

| Процесс | Мощный лазерный луч фокусируется на поверхности материала. Энергия лазера испаряет материал, создавая постоянный след. Могут использоваться различные типы лазеров, такие как волоконный, CO2 и ультрафиолетовый, каждый из которых имеет свои преимущества и ограничения. | Более высокая первоначальная стоимость: Лазерные маркировочные машины могут стоить дороже, чем машины для точечной маркировки. Потенциал теплового повреждения: Мощные лазеры могут повредить чувствительные материалы. Необходимость вентиляции: При лазерной маркировке могут образовываться пары и дым, поэтому необходимо обеспечить надлежащую вентиляцию. |

| Преимущества | Высокая прочность: Знаки глубоко въедаются в материал, что делает их устойчивыми к истиранию, коррозии и другим факторам окружающей среды. Универсальность: Может маркировать широкий спектр материалов, включая металлы, пластики и керамику. Работа в автономном режиме: Может использоваться в местах с ограниченным или отсутствующим электропитанием. | Высокая скорость: Лазерная маркировка - очень быстрый процесс, особенно для простых конструкций. Точность: Может производить высокодетализированную и точную разметку. Чистые метки: Никакого физического контакта с материалом, в результате чего получаются чистые следы без заусенцев. Бесконтактная маркировка: Снижает риск повреждения материала. |

| Недостатки | Снижение скорости маркировки: По сравнению с лазерной маркировкой точечная гравировка - более медленный процесс. Потенциал повреждения поверхности: Чрезмерное усилие может повредить поверхность материала, особенно если речь идет о более мягких материалах. Шумовое загрязнение: Многократные удары стилуса могут создавать шум. | Более высокая первоначальная стоимость: Лазерные маркировочные машины могут стоить дороже, чем машины для точечной маркировки. Потенциал теплового повреждения: Мощные лазеры могут повредить чувствительные материалы. Необходимость вентиляции: При лазерной маркировке могут образовываться пары и дым, поэтому необходимо обеспечить надлежащую вентиляцию. |

Ключевые факторы, которые необходимо учитывать

| Точечная гравировка(Точечный гравер) | Лазерная маркировка(Лазерный маркиратор) | |

| Совместимость материалов | Подходит для: Большинство металлов, включая твердые и мягкие стали, алюминий и нержавеющую сталь. Ограничения: Может не подойти для очень мягких или хрупких материалов, так как чрезмерное усилие может повредить поверхность. | Подходит для: Широкий спектр материалов, включая металлы, пластики, керамику и даже некоторые органические материалы. Ограничения: Выбор типа лазера (волоконный, CO2, УФ) влияет на совместимость материалов. Например, CO2-лазеры хорошо подходят для органических материалов, а волоконные лазеры - для металлов. |

| Глубина и долговечность маркировки | Дип Маркс: Образуют относительно глубокие следы, что делает их очень долговечными. Высокая прочность: Устойчивость к истиранию, коррозии и другим факторам окружающей среды. | Изменяемая глубина: Глубину маркировки можно контролировать, регулируя мощность лазера и время экспозиции. Высокая прочность: Лазерная маркировка, как правило, долговечна, но ее долговечность зависит от материала и параметров лазера. |

| Скорость и эффективность маркировки | Низкая скорость: Медленнее, чем лазерная маркировка, особенно для сложных конструкций. Эффективность: Хорошо подходит для простых, повторяющихся знаков. | Высокая скорость: Возможность маркировки сложных конструкций на высокой скорости. Эффективность: Идеально подходит для крупносерийного производства и сложной маркировки. |

| Качество и эстетика марки | Четкие знаки: Четкие, разборчивые следы. Менее эстетично: Может оставлять шероховатую поверхность. | Высококачественные марки: Позволяет получать следы с высоким разрешением и мелкой детализацией. Эстетически приятный: Чистые, гладкие следы с минимальными повреждениями поверхности. |

| Операционные расходы | Низкая первоначальная стоимость: Как правило, дешевле, чем лазерные маркировочные машины. Снижение эксплуатационных расходов: Снижение затрат на обслуживание и расходные материалы. | Более высокая первоначальная стоимость: Лазерные маркировочные машины могут быть значительно дороже. Более высокие эксплуатационные расходы: Возможность увеличения затрат на обслуживание и расходные материалы, особенно для мощных лазеров. |

| Соображения безопасности | Шумовое загрязнение: Может создавать шум, что требует соответствующей защиты органов слуха. Защита глаз: Для защиты от летящих осколков следует надеть защитные очки. | Безопасность глаз: Лазерные защитные очки необходимы для защиты от лазерного излучения. Огнеопасность: Лазерная маркировка может генерировать тепло и искры, что требует надлежащей вентиляции и мер пожарной безопасности. Вытяжка дыма: Для удаления опасных паров и дыма необходима достаточная вентиляция. |

Выбор правильной технологии

Чтобы принять обоснованное решение, необходимо взвесить ключевые факторы, о которых говорилось ранее. Хотя и точечная гравировка, и лазерная маркировка имеют свои достоинства, оптимальный выбор зависит от конкретных требований.

Матрица принятия решений

- Совместимость материалов: Точечная гравировка превосходно работает с металлами, а лазерная маркировка универсальна для различных материалов.

- Глубина и долговечность маркировки: Точечная гравировка позволяет получить глубокие и долговечные следы, а лазерная маркировка обеспечивает различную глубину и долговечность.

- Скорость и эффективность: Лазерная маркировка быстрее справляется со сложными рисунками, а точечная гравировка подходит для простых, повторяющихся знаков.

- Качество и эстетика марки: Лазерная маркировка обеспечивает превосходное качество и эстетику, а точечная гравировка - четкие, разборчивые знаки.

- Операционные расходы: Точечная гравировка обычно более экономична, в то время как лазерная маркировка может быть более дорогой.

- Безопасность: Оба способа требуют соблюдения мер безопасности, но лазерная маркировка сопряжена с дополнительными рисками.

Тематические исследования

- Автомобильная промышленность: Лазерная маркировка широко используется для маркировки деталей автомобилей, включая компоненты двигателя, детали шасси и электронные модули. Высокая скорость, точность и способность маркировать различные материалы делают ее идеальной для этой отрасли.

- Аэрокосмическая промышленность: Обе технологии находят применение в аэрокосмической промышленности. Точечная маркировка используется для маркировки металлических деталей, в то время как лазерная маркировка применяется для маркировки композитных материалов и электронных компонентов.

- Промышленность медицинского оборудования: Лазерная маркировка обычно используется для маркировки медицинских изделий, включая имплантаты, хирургические инструменты и устройства для доставки лекарств. Его способность создавать точные, чистые и биосовместимые маркировки делает его предпочтительным выбором.

В заключение следует отметить, что и граверы для точечной и лазерной маркировки обладают уникальными преимуществами и ограничениями. Оптимальный выбор зависит от множества факторов, включая совместимость материалов, глубину и долговечность маркировки, скорость и эффективность, качество и эстетику маркировки, эксплуатационные расходы и соображения безопасности. Прежде чем принять решение о покупке, необходимо тщательно оценить ваши конкретные требования к применению и проконсультироваться с специалист по писчебумажным машинам чтобы обеспечить наилучший результат. Учитывая ключевые факторы, рассмотренные в этой статье, и обратившись за профессиональной консультацией, вы сможете сделать осознанный выбор, который удовлетворит ваши потребности и будет способствовать развитию вашего бизнеса.

Recommended Products