Laser Marking Automation: A Comprehensive Analysis and Solution Selection

Faced with increasingly fierce market competition and the growing demand from consumers for personalized and customized products, traditional manual marking methods can no longer meet the needs of large-scale, high-speed production. The introduction of automated laser marking machines has enabled fully automated operations from material loading, positioning, marking, and unloading, greatly reducing labor costs and improving production efficiency.

This article delves into the world of laser marking automation, exploring its principles, advantages, applications, and various available solutions, ultimately guiding you to build the perfect automated laser marking system to meet your needs.

What is Laser Marking Automation?

Laser marking automation integrates automated technologies into the laser marking process, eliminating the need for manual intervention. This involves automating tasks such as part loading/unloading, precise positioning, marking execution, and quality inspection. Automated laser marking machines typically incorporate sophisticated control systems, robotic arms, sensors, and vision systems to achieve seamless and efficient operation. This technology is particularly beneficial for high-volume, repetitive marking tasks common in industries like electronics, automotive, medical devices, and more.

Working Principle of Automated Laser Marking Systems

System Composition:

An automated laser marking system comprises several key components working in synergy:

- Laser Source: The heart of the system, generating the laser beam for marking. Common types include fiber, CO2, and UV lasers, each suited for different materials.

- Control System: The brains of the operation, managing the laser parameters, motion platform, and other system components.

- Motion Platform: Precisely moves the workpiece or laser head to achieve the desired marking location.

- Robotic Arm (Optional): Handles part loading/unloading and manipulation for complex marking tasks.

- Sensors: Detect part presence, position, and orientation, ensuring accurate marking.

- Vision System (Optional): Employs cameras and image processing to precisely locate parts and verify marking quality.

- Loading/Unloading Mechanism (Optional): Automates the process of feeding parts into the marking station and removing finished parts.

Workflow:

The automated laser marking process typically follows these steps:

Part Preparation: Workpieces are placed on a conveyor, tray, or other staging area.

Automated Loading: A robotic arm or loading mechanism picks up a workpiece and places it in the marking station.

Precise Positioning: Sensors or a vision system accurately locates the workpiece, ensuring correct marking placement.

Laser Marking Execution: The control system triggers the laser to mark the workpiece according to pre-programmed parameters.

Quality Inspection (Optional): A vision system or sensor verifies the marking quality, checking for accuracy and legibility.

Automated Unloading: The robotic arm or unloading mechanism removes the marked workpiece and places it in a designated area.

What are the Advantages of Automated Laser Marking Systems?

Automating laser marking offers numerous benefits:

1. Improve production efficiency: Automated laser marking machines can maintain a high-speed and efficient working state during continuous production, reduce manual intervention, shorten production cycles and costs, thereby improving production efficiency.

2. Improve accuracy: Automated laser marking machines can precisely control the position, shape, and depth of marking, avoiding errors in manual operation and improving the quality and accuracy of marking.

3. Strong traceability: Automated laser marking machines can record the production data of each product, including marking time, location, operator, and other information, which is convenient for product traceability and quality management.

4. Reduce labor costs: Automated laser marking machines are simple to operate and only require a small amount of professional personnel for maintenance, reducing training and labor costs.

5. High safety: Automated laser marking machines can automatically detect and respond to abnormal situations in a continuous working state, avoiding some safety risks and accidents. At the same time, automation minimizes the operator’s interaction with the laser, thereby improving safety.

Applications of Automated Laser Marking

The applications of automated laser marking are vast and span across diverse indust:

Электронная промышленность: Automated laser marking machines can mark and engrave electronic components, such as resistors, capacitors, and semiconductor chips.

Machining: Mark and engrave metal or plastic parts to identify the model, size, batch, and other information of the parts.

Medical Industry: It can be used for marking and engraving on medical devices, such as surgical instruments, implants, and medical packaging.

Food Industry: Automated laser marking machines can mark and code food packaging to trace the production date, shelf life, and other information of the food.

Автомобиль: Marking of engine parts, chassis components, dashboards, and lighting systems.

Four Types of Automated Laser Marking Solutions

Automated laser marking solutions are designed to improve the speed, accuracy, and efficiency of laser marking processes. Here are four common types of automated laser marking solutions:

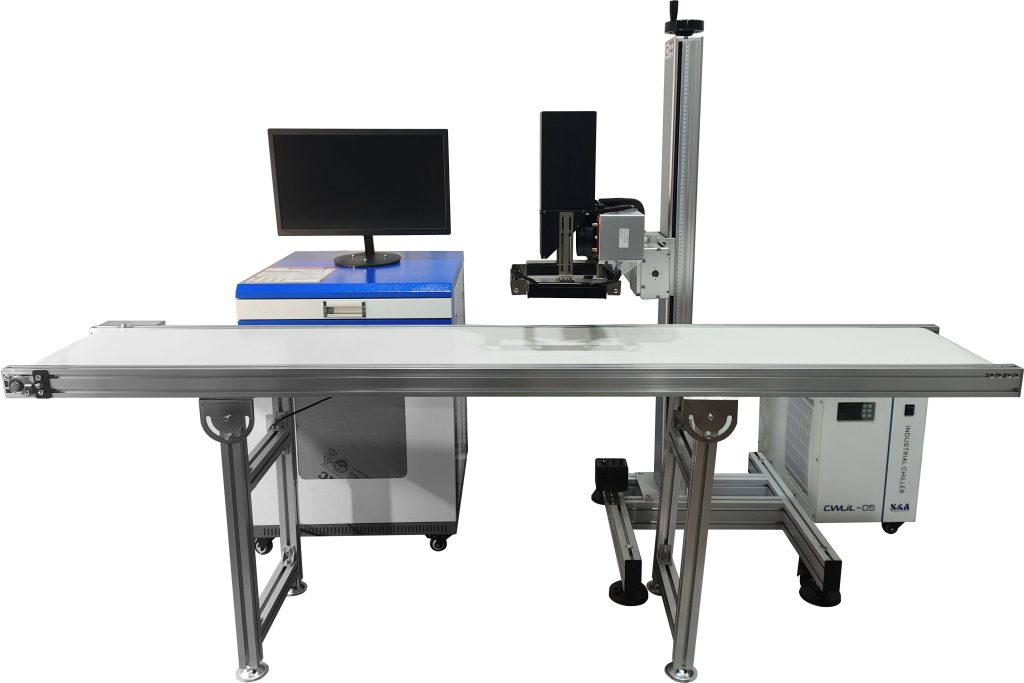

Online Solutions

Онлайн решения integrate the laser marking machine directly into the production line. This allows for seamless marking of parts as they move along the conveyor or production flow.

Преимущества:

High throughput and fast marking speeds.

Ideal for high-volume, continuous production.

Reduced manual handling and labor costs.

Соображения:

Requires careful integration with the existing production line.

May require custom design and engineering.

Less flexible for handling different part types or marking requirements.

CCD Solutions

CCD (Charge-Coupled Device) solutions use cameras and vision systems to precisely locate and identify parts before marking. The CCD camera captures an image of the part, and the vision system analyzes the image to determine the exact position and orientation of the part. The laser marking machine then uses this information to accurately place the mark.

Преимущества:

High marking accuracy and repeatability.

Suitable for applications with tight tolerances or complex marking patterns.

Can handle variations in part placement or orientation.

Соображения:

Vision system setup and programming may require expertise.

Cycle times may be slightly longer compared to online solutions.

Higher initial investment due to the vision system.

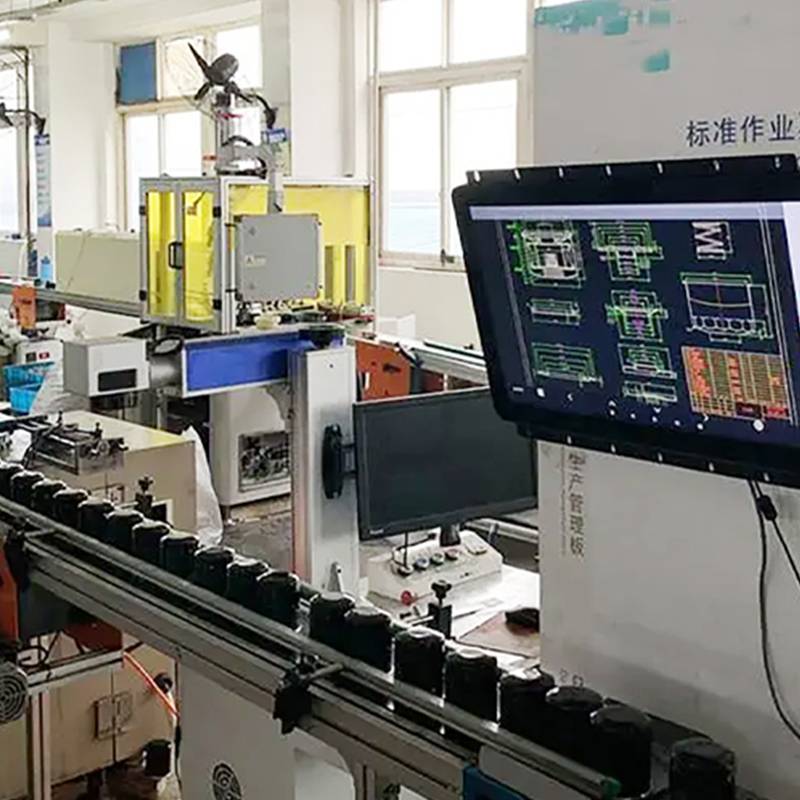

Flying Solutions

Летающие решения involve marking on parts that are in continuous motion. The laser beam is directed onto the moving workpiece, and the marking is performed “on-the-fly.”

Преимущества:

Extremely high marking speeds.

Ideal for high-throughput applications with continuous flow.

Eliminates the need for precise part stopping and positioning.

Соображения:

Requires precise synchronization between the laser marking system and the moving parts.

Complex control and coordination.

May be limited in marking complexity or part types.

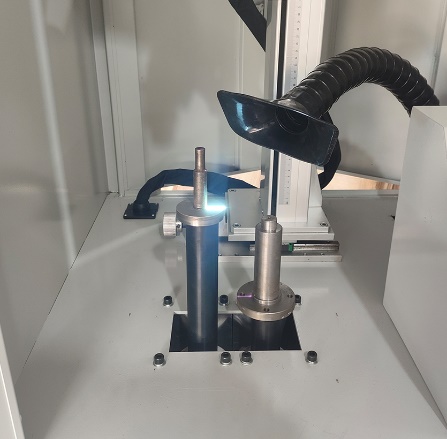

Multi-Axis Systems

Multi-axis systems use multiple axes of motion to achieve marking on complex 3D surfaces or curved parts. The laser head or workpiece is manipulated along multiple axes (e.g., X, Y, Z, rotation) to follow the contours of the part and create the desired mark.

Преимущества:

Enables marking on complex shapes and surfaces.

High flexibility for various marking applications.

Can create intricate and detailed marks.

Соображения:

Requires advanced motion control and programming.

Higher system cost and complexity.

May have slower marking speeds compared to other solutions.

Choose Zixu to Start Building Your Automated Laser Solution

Компания Zixu is a leading provider of laser marking solutions, specializing in the design and manufacturing of high-quality automated laser marking systems. With years of experience and a deep understanding of laser technology, Zixu offers a comprehensive range of solutions tailored to meet diverse customer needs. Our expertise extends from standalone marking machines to fully integrated automated systems, incorporating the latest advancements in laser technology, robotics, and vision systems.

We are committed to providing:

- High-Performance Equipment: Our machines are built with robust components and cutting-edge technology to ensure reliable and consistent performance.

- Customized Solutions: We work closely with our clients to understand their specific requirements and develop tailored automated laser marking solutions.

- Comprehensive Support: We offer comprehensive after-sales support, including installation, training, and maintenance services.

Contact Zixu today to discuss your laser marking automation needs and let us help you build the perfect solution for your business. Our team of experts will guide you through the process, from initial consultation to system integration, ensuring a seamless and successful implementation.

Recommended Products